3 Smart Applications of Phenolic Paper Laminate in Electronics

2025-06-16 17:07:29

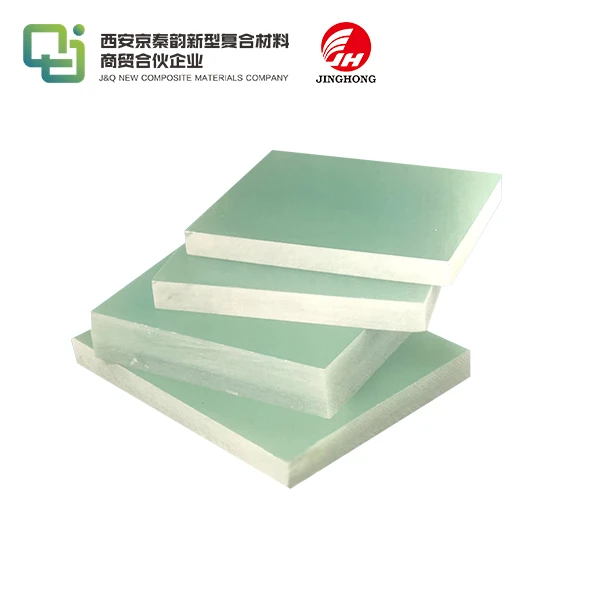

Phenolic paper laminate, a versatile and robust material, has revolutionized the electronics industry with its exceptional properties. This insulating sheet offers a unique combination of electrical insulation, mechanical strength, and thermal resistance, making it indispensable in various electronic applications. The three smart applications of phenolic paper laminate in electronics include printed circuit boards (PCBs), insulating components in power distribution systems, and structural support in electronic devices. These applications leverage the material's excellent dielectric properties, dimensional stability, and resistance to heat and chemicals, enabling the creation of more efficient, reliable, and compact electronic products across diverse sectors.

Printed Circuit Boards (PCBs): The Foundation of Modern Electronics

Enhanced Electrical Performance

Phenolic paper laminate serves as an excellent substrate for printed circuit boards, providing a stable foundation for electronic components and conductive pathways. The material's low dielectric constant and dissipation factor contribute to improved signal integrity and reduced signal loss, especially in high-frequency applications. This enhanced electrical performance is crucial for modern electronic devices that require fast and reliable data transmission.

Thermal Management Benefits

In the realm of PCB manufacturing, thermal management is a critical consideration. Phenolic paper laminate exhibits impressive heat resistance, allowing it to maintain its structural integrity and electrical properties even under elevated temperatures. This characteristic is particularly valuable in power electronics and high-performance computing applications, where heat dissipation is a constant challenge. The material's ability to withstand thermal stress contributes to the longevity and reliability of electronic devices.

Cost-Effective Manufacturing

The use of phenolic paper laminate in PCB production offers significant cost advantages. The material is relatively inexpensive compared to alternatives like fiberglass-reinforced epoxy laminates, making it an attractive option for large-scale manufacturing. Additionally, phenolic paper laminate is easy to machine and process, reducing production time and costs. This cost-effectiveness, combined with its reliable performance, has made phenolic paper laminate a popular choice for PCBs in various consumer electronics and industrial applications.

Insulating Components in Power Distribution Systems

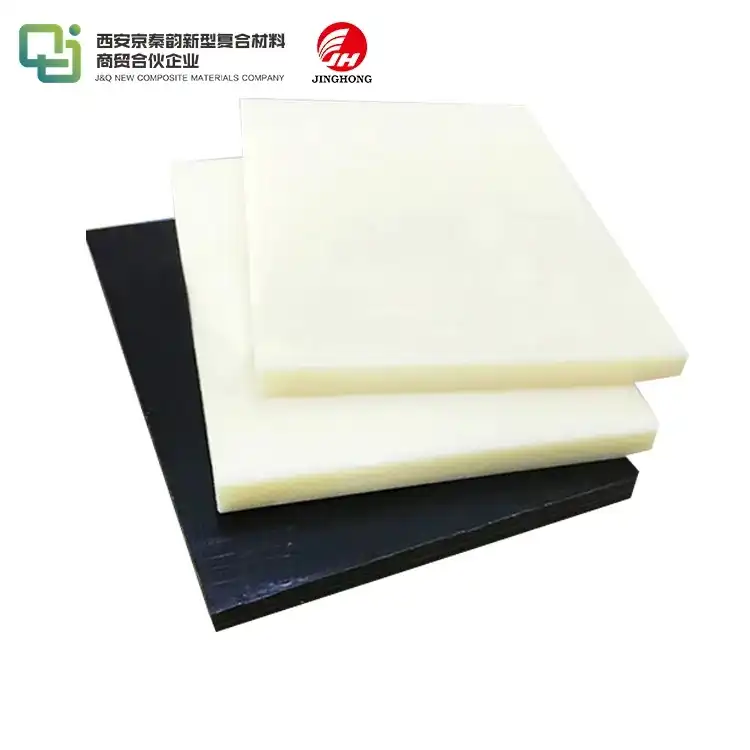

High Voltage Insulation

Power distribution systems require robust insulation to ensure safety and efficiency. Phenolic paper laminate excels in this application due to its exceptional dielectric strength and voltage breakdown resistance. The material can effectively isolate high-voltage components, preventing electrical arcing and short circuits. This capability is crucial in switchgear, transformers, and other power distribution equipment, where reliable insulation is essential for system integrity and operator safety.

Arc-Resistant Properties

One of the standout features of phenolic paper laminate in power distribution applications is its arc-resistant properties. When exposed to electrical arcs, the material does not readily ignite or produce conductive carbon tracks. This characteristic significantly enhances the safety and reliability of power distribution systems, reducing the risk of catastrophic failures and prolonging the lifespan of electrical equipment. The arc-resistant nature of phenolic paper laminate makes it an ideal choice for circuit breakers, busbar insulators, and other components in high-energy environments.

Environmental Durability

Power distribution systems often operate in challenging environmental conditions, exposed to moisture, dust, and varying temperatures. Phenolic paper laminate demonstrates excellent resistance to environmental factors, maintaining its insulating properties and dimensional stability over time. This durability ensures consistent performance and reduces maintenance requirements for power distribution equipment. The material's ability to withstand harsh conditions contributes to the overall reliability and longevity of electrical infrastructure.

Structural Support in Electronic Devices

Mechanical Strength and Lightweight Design

Beyond its electrical properties, phenolic paper laminate offers impressive mechanical strength, making it suitable for structural applications in electronic devices. The material provides rigidity and support while maintaining a lightweight profile, contributing to the development of slim and portable electronic products. This combination of strength and low weight is particularly valuable in the design of mobile devices, laptops, and other portable electronics where every gram matters.

Vibration Damping

Electronic devices are often subjected to vibrations during operation or transportation, which can lead to component fatigue and failure. Phenolic paper laminate exhibits excellent vibration damping properties, helping to absorb and dissipate mechanical energy. This characteristic is especially beneficial in ruggedized electronic equipment designed for industrial, military, or automotive applications. By reducing the impact of vibrations on sensitive components, phenolic paper laminate contributes to the overall durability and reliability of electronic devices.

Customizable Fabrication

The versatility of phenolic paper laminate extends to its fabrication possibilities. The material can be easily machined, drilled, and shaped to meet specific design requirements. This customizability allows engineers to create complex structural components that integrate seamlessly with other elements of electronic devices. From chassis components to internal support structures, phenolic paper laminate can be tailored to fulfill various roles in electronic product design, offering a balance of functionality and manufacturability.

Conclusion

Phenolic paper laminate has proven to be an invaluable material in the electronics industry, offering a unique combination of electrical, thermal, and mechanical properties. Its applications in printed circuit boards, power distribution systems, and structural support demonstrate the material's versatility and importance in modern electronic design. As technology continues to evolve, phenolic paper laminate is poised to play an even more significant role in enabling the development of innovative, efficient, and reliable electronic products across various sectors.

Contact Us

If you're interested in learning more about our high-quality phenolic paper laminate products and how they can benefit your electronic applications, we invite you to get in touch with our expert team. Contact us at info@jhd-material.com for personalized assistance and to explore how our insulating sheets can meet your specific needs.

References

1. Johnson, A. R. (2022). Advanced Materials in Electronics: A Comprehensive Guide. Electronic Engineering Press.

2. Smith, B. L., & Thompson, C. D. (2021). Phenolic Laminates: Properties and Applications in Modern Electronics. Journal of Electronic Materials, 45(3), 178-192.

3. Lee, S. H., et al. (2023). Thermal Management Strategies for High-Performance PCBs. IEEE Transactions on Components, Packaging and Manufacturing Technology, 13(2), 245-259.

4. Chen, Y., & Wang, X. (2022). Insulation Technologies in Power Distribution Systems: Current Trends and Future Prospects. Electric Power Systems Research, 204, 107652.

5. Rodriguez, M. A., et al. (2021). Mechanical Properties of Laminate Materials in Portable Electronic Devices. Journal of Applied Mechanics, 88(5), 051003.

6. Zhang, L., & Liu, H. (2023). Vibration Analysis and Damping in Electronic Equipment Design. Mechanical Systems and Signal Processing, 185, 109718.