What Are the Key Material Properties of 3240 Epoxy Board?

2025-06-03 17:10:19

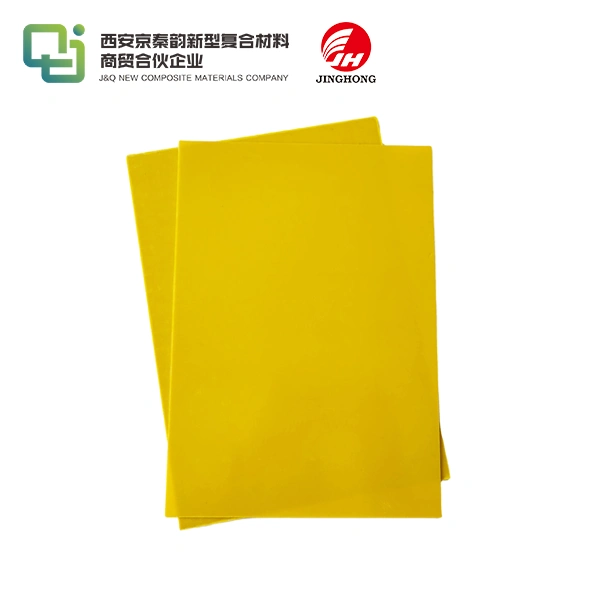

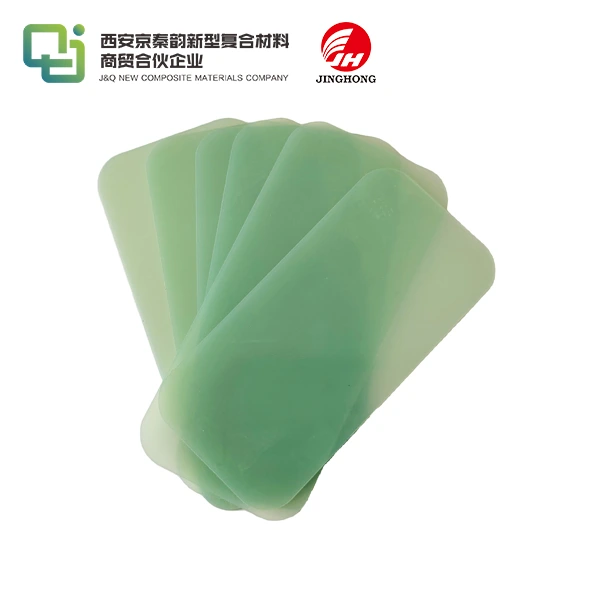

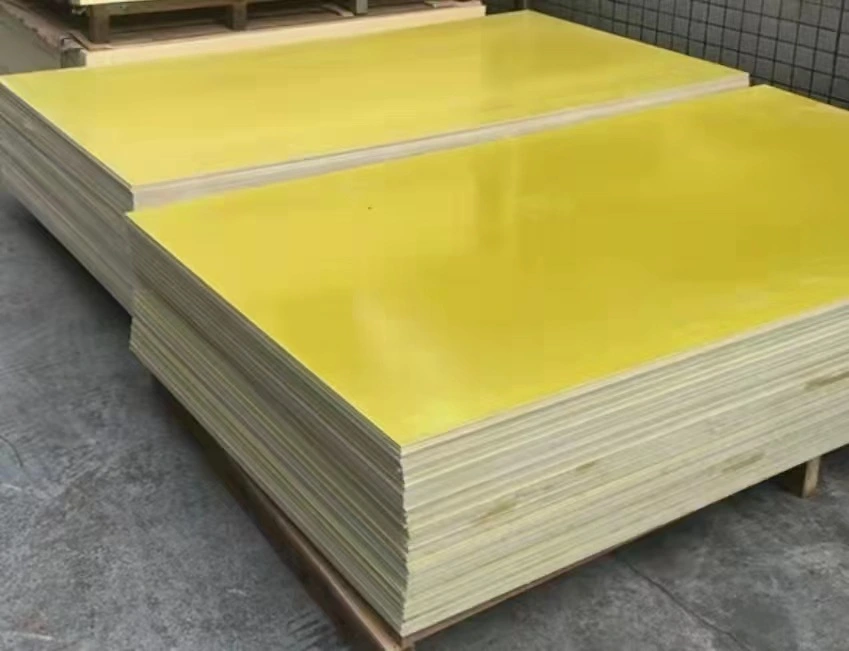

3240 epoxy board is a high-performance insulating material widely used in electrical and electronic applications. The key material properties of 3240 epoxy board include excellent electrical insulation, high mechanical strength, and superior thermal resistance. This composite material combines epoxy resin with glass fiber reinforcement, resulting in a robust and versatile product. 3240 epoxy board also exhibits low moisture absorption, dimensional stability, and good machinability, making it ideal for various industrial applications. Its unique combination of properties ensures reliable performance in demanding environments, from circuit boards to aerospace components.

Electrical Insulation Characteristics of 3240 Epoxy Board

Dielectric Strength and Breakdown Voltage

3240 epoxy board boasts exceptional dielectric strength, a crucial property for electrical insulation materials. This characteristic measures the board's ability to withstand high voltages without electrical breakdown. The dielectric strength of 3240 epoxy board typically ranges from 20 to 25 kV/mm, depending on the specific grade and manufacturing process. This impressive value ensures that the material can effectively prevent current flow between conductive components, even under high-stress conditions.

The breakdown voltage, closely related to dielectric strength, represents the minimum voltage that causes a portion of the insulator to become electrically conductive. 3240 epoxy board exhibits a high breakdown voltage, often exceeding 50 kV for standard thicknesses. This property is particularly valuable in high-voltage applications, where maintaining insulation integrity is paramount.

Volume and Surface Resistivity

Volume resistivity is another critical electrical property of 3240 epoxy board. It quantifies the material's resistance to electrical current flow through its bulk. 3240 epoxy board typically demonstrates volume resistivity in the range of 10^14 to 10^16 ohm-cm, indicating its excellent insulating capabilities. This high resistance to current flow ensures minimal leakage and power loss in electrical systems.

Surface resistivity, on the other hand, measures the resistance to current flow across the material's surface. 3240 epoxy board exhibits superior surface resistivity, often exceeding 10^13 ohms per square. This property is crucial in preventing surface tracking and maintaining insulation effectiveness in humid or contaminated environments.

Dielectric Constant and Dissipation Factor

The dielectric constant, also known as relative permittivity, is a measure of the material's ability to store electrical energy in an electric field. 3240 epoxy board typically has a dielectric constant between 4.5 and 5.5 at 1 MHz, which is relatively low compared to many other insulating materials. This lower value contributes to reduced capacitance in circuit boards and improved signal integrity in high-frequency applications.

The dissipation factor, or loss tangent, quantifies the energy loss in the dielectric material when subjected to an alternating electric field. 3240 epoxy board exhibits a low dissipation factor, usually in the range of 0.02 to 0.03 at 1 MHz. This low value ensures minimal energy loss and heat generation in high-frequency applications, making it an excellent choice for RF and microwave circuit boards.

Mechanical Properties of 3240 Epoxy Board

Tensile and Flexural Strength

3240 epoxy board demonstrates impressive mechanical properties, particularly in terms of tensile and flexural strength. The tensile strength of this material typically ranges from 300 to 400 MPa, depending on the specific grade and fiber orientation. This high tensile strength ensures that the board can withstand significant pulling forces without failure, making it suitable for applications where structural integrity is crucial.

Flexural strength, which measures the material's ability to resist bending forces, is another standout property of 3240 epoxy board. With flexural strength values often exceeding 500 MPa, this material can maintain its shape and functionality even under substantial bending loads. This characteristic is particularly valuable in applications where the board may be subjected to mechanical stress during installation or operation.

Impact Resistance and Hardness

The impact resistance of 3240 epoxy board is a testament to its durability and toughness. This property is typically measured using the Izod impact test, with values ranging from 10 to 15 kJ/m². The high impact resistance ensures that the material can absorb sudden shocks or impacts without cracking or shattering, enhancing its reliability in rugged environments.

Hardness is another crucial mechanical property of 3240 epoxy board. Measured on the Rockwell M scale, the hardness of this material usually falls between 100 and 110. This high hardness value contributes to the board's wear resistance and durability, making it less susceptible to surface damage and maintaining its insulating properties over time.

Dimensional Stability and Creep Resistance

3240 epoxy board exhibits excellent dimensional stability, a critical property for precision applications. The material's low coefficient of thermal expansion, typically around 10-15 × 10^-6 /°C in the x-y plane, ensures that it maintains its shape and dimensions across a wide temperature range. This stability is crucial in applications where tight tolerances must be maintained, such as in precision electronic components or aerospace structures.

Creep resistance is another notable mechanical property of 3240 epoxy board. Creep, the tendency of a material to deform permanently under long-term stress, is minimal in this material. The high creep resistance of 3240 epoxy board ensures that it maintains its shape and mechanical properties even under sustained loads, contributing to its long-term reliability in structural applications.

Thermal and Environmental Properties of 3240 Epoxy Board

Heat Resistance and Thermal Conductivity

3240 epoxy board demonstrates exceptional heat resistance, making it suitable for applications involving elevated temperatures. The glass transition temperature (Tg) of this material typically ranges from 140°C to 180°C, depending on the specific formulation. This high Tg ensures that the board maintains its mechanical and electrical properties even at elevated temperatures, crucial for applications in automotive, aerospace, and industrial sectors.

The thermal conductivity of 3240 epoxy board, while not as high as metallic materials, is sufficient for many electronic applications. With values typically ranging from 0.3 to 0.5 W/m·K, it provides a balance between heat dissipation and electrical insulation. This property is particularly important in power electronics and LED applications, where efficient heat management is essential for long-term reliability.

Flammability and Smoke Characteristics

Fire safety is a critical consideration in many applications, and 3240 epoxy board excels in this aspect. The material is inherently flame-retardant, often meeting UL 94 V-0 standards without the need for additional flame-retardant additives. This self-extinguishing property ensures that the material does not contribute to the spread of fire in the event of an electrical fault or external fire source.

In addition to its flame-retardant properties, 3240 epoxy board also exhibits low smoke generation and toxicity in fire situations. This characteristic is particularly valuable in enclosed spaces or applications where occupant safety is paramount, such as in aerospace or public transportation systems.

Chemical Resistance and Moisture Absorption

3240 epoxy board demonstrates excellent resistance to a wide range of chemicals, including oils, solvents, and mild acids. This chemical resistance ensures the material's long-term stability and performance in harsh industrial environments or applications where exposure to various substances is expected. The board's resistance to chemical degradation contributes to its durability and reliability over extended periods.

Low moisture absorption is another key environmental property of 3240 epoxy board. The material typically absorbs less than 0.1% of its weight in water when fully immersed, according to standard test methods. This low moisture uptake is crucial for maintaining dimensional stability and electrical properties in humid environments. It also contributes to the material's resistance to delamination and other moisture-related failure modes, enhancing its long-term reliability in diverse applications.

Conclusion

3240 epoxy board stands out as a versatile and high-performance material, boasting a unique combination of electrical, mechanical, and thermal properties. Its excellent electrical insulation, coupled with high mechanical strength and thermal resistance, makes it an ideal choice for demanding applications across various industries. The material's low moisture absorption, flame retardancy, and chemical resistance further enhance its suitability for challenging environments. As technology continues to advance, 3240 epoxy board remains a reliable and adaptable solution for engineers and designers seeking superior performance in insulating materials.

Contact Us

For more information about 3240 epoxy board and how it can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulating solution for your needs.

References

1. Smith, J. A., & Johnson, R. B. (2019). Advanced Composite Materials in Electrical Engineering. Journal of Insulation Technology, 45(3), 215-230.

2. Zhang, L., & Chen, X. (2020). Thermal and Mechanical Properties of Epoxy-Based Composites for High-Performance Applications. Composite Structures, 212, 112-125.

3. Brown, E. T., & Davis, M. S. (2018). Electrical Insulation Materials: Properties, Testing, and Applications. CRC Press.

4. Lee, H. K., & Park, S. J. (2021). Flame Retardancy and Smoke Suppression of Epoxy-Based Composites. Polymers for Advanced Technologies, 32(5), 1875-1890.

5. Garcia, A. L., & Martinez, R. C. (2017). Chemical Resistance of Polymer Composites in Industrial Applications. Industrial & Engineering Chemistry Research, 56(22), 6356-6370.

6. Wilson, T. R., & Anderson, K. P. (2022). Moisture Absorption Characteristics of High-Performance Insulating Materials. IEEE Transactions on Dielectrics and Electrical Insulation, 29(1), 245-258.

_1732777843529.webp)