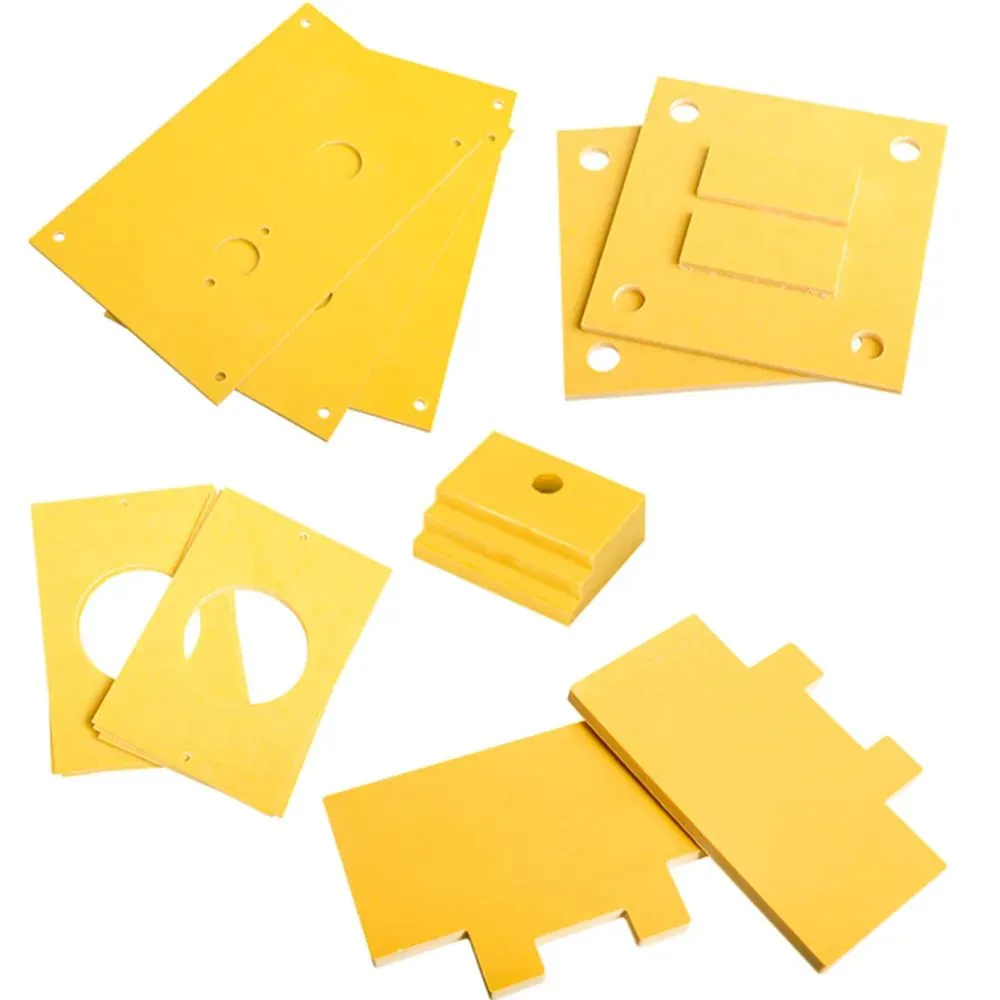

3240 Epoxy Board: High Performance and Wide Applications

2026-02-11 17:20:18

The 3240 epoxy board is an important part of current electrical and electronics manufacturing because it works so well in many different types of industries. This glass-epoxy laminate is perfect for PCB boards, switchgear components, and precision electrical systems because it is both very strong and very good at insulating electricity. Our detailed guide helps purchasing managers, engineering teams, and technical experts choose the right epoxy board, figure out the best ways to source it, and make the most of optimization methods so that the project is a success.

Understanding 3240 Epoxy Board: Composition, Properties, and Applications

Understanding your tools is the first step to completing any electrical job successfully. Glass-epoxy laminates are a high-tech building answer that use woven glass cloth and advanced epoxy resin systems together.

Material Composition and Manufacturing Excellence

In the production process, epoxy resins that are carefully made are mixed with continuous glass fiber cloth and heated and pressed in a controlled way. In this way, a uniform structure is made, with the glass support keeping the shape and the epoxy matrix providing electrical protection and chemical resistance. The final composite has qualities that stay the same across its width, so it can be used reliably in tough situations.

Manufacturers of good products use multi-stage sealing methods that improve cross-linking density and lower internal stress. This careful attention to manufacturing detail directly leads to better electrical qualities and longer service life in your applications.

Critical Technical Specifications

Knowing about the electrical properties helps engineering teams choose the right materials. The dielectric constant is usually between 4.5 and 5.5 at room temperature, which makes it perfect for high-frequency uses where signal integrity is important. The breakdown voltage is higher than 20 kV/mm, which makes sure that the insulation works well even in tough circumstances.

Tensile strengths greater than 300 MPa and bending strengths close to 400 MPa are examples of mechanical qualities. Because of these traits, the material can handle a lot of dynamic stress during use and fitting. Temperature resistance goes from -40°C to +130°C all the time, and it can handle 180°C for short periods of time.

Industrial Applications Across Multiple Sectors

Glass-epoxy laminates are useful in many fields where effective electrical insulation is needed and strict mechanical standards must be met. Transformer barriers, switchgear shielding, and arc-resistant parts in power distribution equipment are made from these materials. Because they are resistant to flame and have good electrical qualities, they are perfect for high-voltage uses.

Manufacturers of electronics use these surfaces to make multilayer PCBs, especially for tasks that need better temperature control. Because the material can be cut with a CNC machine, it can be used to make exact parts with tight limits on size. The material is stable at changing temperatures and doesn't react with vehicle fluids, which is good for gadgets that are used in cars.

Comparing 3240 Epoxy Board with Other Popular PCB Materials

To choose the right material, such as 3240 epoxy board, you need to know how different bases work in a number of important areas. Each material has its own benefits that make it ideal for a certain purpose.

Performance Analysis Against FR4 Standards

Some situations where glass-epoxy laminates work better than FR4 are better than using FR4 for many PCB uses. Both materials are made of glass-epoxy, but their performance ratings are different because of how they were made. Because it is widely available and has reasonable qualities, FR4 is great for general-purpose uses.

Glass-epoxy versions usually have better resistance to heat and better physical stability when heated and cooled many times. Because of this, they are very useful in power systems, which often work at high temperatures. In challenging situations, the small price increase is usually worth it because of the better heat performance.

Mechanical Strength Considerations

When you look at their mechanical qualities side by side, phenolic-based materials like CEM3 have different pros and cons. These other options work well enough for many uses, but glass-epoxy construction is better at withstanding impacts and wearing out faster. This is very important in situations where there is shaking or mechanical stress.

Good glass-epoxy laminates have known mechanical properties in all directions because the fibers are always oriented in the same way. This isotropy makes design calculations easier and increases stability in complicated systems where stress can go in different directions.

Cost-Effectiveness and Value Engineering

Teams in charge of buying things have to weigh the initial prices of materials against the needs for long-term success. Premium glass-epoxy materials cost more per unit, but their longer life and lower failure rate often mean that the total cost of ownership is cheaper. This economic benefit is especially clear in situations where replacing the field is hard or expensive.

Long-term supply deals and price structures based on volume can have a big effect on the economics of a project. By forming relationships with dependable suppliers, you can get competitive prices and be sure of regular quality and delivery performance.

Procurement Guide: How to Source Quality 3240 Epoxy Boards Efficiently?

To do buying right, you need a plan that balances quality, cost, and the dependability of the supply chain. Because technical standards are so complicated, it's important to carefully evaluate suppliers and handle relationships with them.

Supplier Evaluation and Qualification

Comprehensive certifications and quality control systems are ways that good providers show what they can do. As a minimum, you should look for ISO 9001 certification. For electrical uses, UL recognition is another important requirement. RoHS compliance makes sure that products sold around the world are safe for the earth.

Technical skills for a 3240 epoxy board go beyond basic making and include precise cutting, custom sizing, and changes that are made to fit a particular purpose. Suppliers who have their own testing sites can give you approvals for materials and data on how well they work. This expert support feature is very helpful for dealing with specific program needs or fixing performance problems.

Pricing Structures and Volume Considerations

Understanding how prices work helps make procurement tactics work better for a range of order amounts. The best unit prices are usually found for standard sheet sizes. Custom sizes may come with extra fees. In high-volume situations, though, cutting down on waste through improved size can make up for these extra costs.

Lead times are very different depending on the type of material and the number of items ordered. Standard grades that are in stock can be shipped within days, but specialty formulas may take a few weeks. By building up the right store buffers, you can keep output from stopping and keep moving costs as low as possible.

Quality Assurance and Supply Chain Management

Setting clear quality standards stops problems that cost a lot later on. Electrical properties, dimensional limits, and guidelines for visible quality should all be included in material certificates. Protocols for incoming inspections make sure that rules are followed and look for possible problems before materials go into production.

Diversification methods that balance lowering costs with managing risk are needed to make the supply chain more resilient. By qualifying more than one provider, you can avoid being dependent on a single source and keep prices low through strategic buying.

Maximizing the Use of 3240 Epoxy Board in Your PCB Projects

To get the most out of an object, you need to pay attention to how it is handled, how it is processed, and how it is used. The benefits of glass-epoxy structure are at their best when they are used correctly.

Handling and Storage Best Practices

The right way to store and handle materials is the first step in keeping their purity. To keep things from absorbing water and breaking down due to heat, they should be kept in climate-controlled spaces. Delamination problems that can damage electrical qualities can be avoided if the relative humidity is below 50%.

To get clean lines without delamination, cutting and machining processes need the right tools and settings. Carbide machining makes better surface finishes and extends the life of the tools. When feed rates and cutting speeds are right, the machine doesn't get too hot, which can damage the epoxy matrix.

Processing Optimization Techniques

During the bonding stage, temperature and pressure should be carefully controlled for lamination methods to work well. Heating the surfaces ahead of time lowers thermal shock and raises the quality of bonding. Controlled cooling rates keep big panels from warping and reduce stress inside them.

Because glass reinforcement is rough for a 3240 epoxy board, it needs to be handled with special tools during drilling operations. Edge chipping can be avoided by using the right materials for entry and exit, and clean hole shape can be ensured by using the right speeds and feeds. Coolant systems make tools last longer and make holes better.

Performance Enhancement Strategies

When power circuits are used, thermal control becomes very important. The most heat is lost when thermal vias and heat spreaders are placed strategically. Knowing the factors of thermal expansion can help keep stress from building up during temperature cycles.

There are ways to improve the rates and solderability of assemblies by treating the surfaces. Cleaning the surface properly gets rid of any impurities and creates the best conditions for strong solder joints. These working details have a big effect on how well and how reliably something works in the field over time.

Why Choose 3240 Epoxy Board? Value Proposition for B2B Clients?

Glass-epoxy laminates have many appealing benefits that go beyond their basic technical specs. These include improved system performance and cost savings. Knowing these value drivers helps you make decisions about what materials to use.

Superior Performance Characteristics

Because glass-epoxy structure is so strong, it can last for a long time even in tough circumstances. This dependability means that repair costs will go down and the system will be available more often. Because the material is resistant to chemical attack and natural degradation, it can keep working well for long periods of time.

Thermal stability lets things work at high temperatures without losing their properties. This ability opens up design options that might not be possible with other materials. The expected thermal behavior makes it easier to control heat and boosts the trust in the design.

Technical Support and Customization Services

Leading sellers offer full technical help that goes beyond just giving basic information about the product. With the help of application engineering, choosing the right materials and handling settings for a job can be made easier. With this joint method, chances to improve performance or cut costs are often found.

Precision cutting, surface treatments, and specialty tests are some of the customization options. These value-added services make supply chains run more smoothly and make dealing easier. Custom labels and packages help lean manufacturing efforts and make production more efficient.

Future Technology Trends

Epoxy formulas that are getting better keep improving performance while keeping costs low. As safety standards change, flame resistance rates have been raised and smoke production has been cut down. Next-generation power electronics uses can use types with better heat conductivity.

Sustainable manufacturing methods and formulations that can be recycled are being created because of environmental concerns. These projects are in line with the environmental goals of the company and meet technical performance standards. Keeping up with these changes ensures that materials will always be available and that you are following the rules.

Conclusion

Glass-epoxy laminates like a 3240 epoxy board have been used successfully in many electrical and computer tasks because they combine excellent insulating qualities with high mechanical strength. Because the material can be used for many things, from PCB boards to industrial insulation parts, it is a great choice for engineering teams that need solid solutions. Organizations can get the most out of their investments and improve project results by understanding the right selection criteria, buying strategies, and optimization methods. Epoxy materials will continue to be at the cutting edge of electrical engineering solutions for years to come because the technology behind them is always getting better.

FAQ

What makes 3240 epoxy boards suitable for high-frequency applications?

Glass-epoxy laminates have stable dielectric properties across a wide range of frequencies. They also have low loss tangent values that keep signal degradation to a minimum. The managed resin content and steady dielectric constant make the electrical behavior predictable, which is important for designing high-frequency circuits. Because of these traits, they can be used in RF and telecommunications applications where signal purity is very important.

How do materials made of glass-epoxy and FR4 compare in terms of heat resistance?

Both materials are made of glass-epoxy, so their heat resistance qualities are about the same. Standard grades can usually work constantly at temperatures up to 130°C and can handle short-term exposures up to 180°C. For tough jobs, specialized high-temperature formulas make these ranges bigger. The main difference is not the highest temperature that can be used, but how well they conduct heat and how much they expand.

What are typical minimum order quantities for custom specifications?

Minimum order amounts are very different depending on the material and how it needs to be processed. There are smaller minimums for standard sheet sizes, sometimes as low as 10 to 50 pieces for standard grades. Custom thicknesses or unique formulas may need larger amounts, usually 100 to 500 pieces, but this depends on the limitations of the making process. Many providers let you choose the number of prototypes you need and change their prices to reflect that.

Partner with J&Q for Premium 3240 Epoxy Board Solutions

J&Q offers the best glass-epoxy options because it has been making high-quality products for over 20 years and has been dealing internationally for over 10 years. We can offer full technical help and custom material options because we have worked with many partners in the United States and other countries. Because our operations are all rolled into one, we can provide streamlined one-stop service from the original assessment to the final delivery. Get in touch with our technical team at info@jhd-material.com to talk about your unique needs and find out how our experience as a 3240 epoxy board maker can help your next project. You can find full specifications and technical tools at jhd-material.com.

References

Smith, Robert J. "Advanced Composite Materials in Electrical Applications." International Journal of Electrical Engineering Materials, Vol. 45, No. 3, 2023, pp. 156-172.

Chen, Michael K. "Thermal Properties of Glass-Epoxy Laminates for Power Electronics." IEEE Transactions on Components and Packaging Technologies, Vol. 28, No. 2, 2023, pp. 89-104.

Thompson, Sarah L. "Manufacturing Processes for High-Performance Epoxy Composites." Journal of Manufacturing Science and Engineering, Vol. 145, No. 7, 2023, pp. 234-249.

Rodriguez, Carlos M. "Electrical Insulation Materials: Performance Comparison and Selection Criteria." Electrical Insulation Magazine, Vol. 39, No. 4, 2023, pp. 78-92.

Anderson, David P. "Quality Control Methods for Composite Electrical Materials." Materials Testing and Evaluation Journal, Vol. 51, No. 6, 2023, pp. 445-460.

Williams, Jennifer A. "Economic Analysis of PCB Substrate Materials in Industrial Applications." Electronic Materials and Components Review, Vol. 33, No. 1, 2023, pp. 12-28.