G10 Epoxy Board Applications and Advantages in Rail Transit

2026-02-12 16:47:02

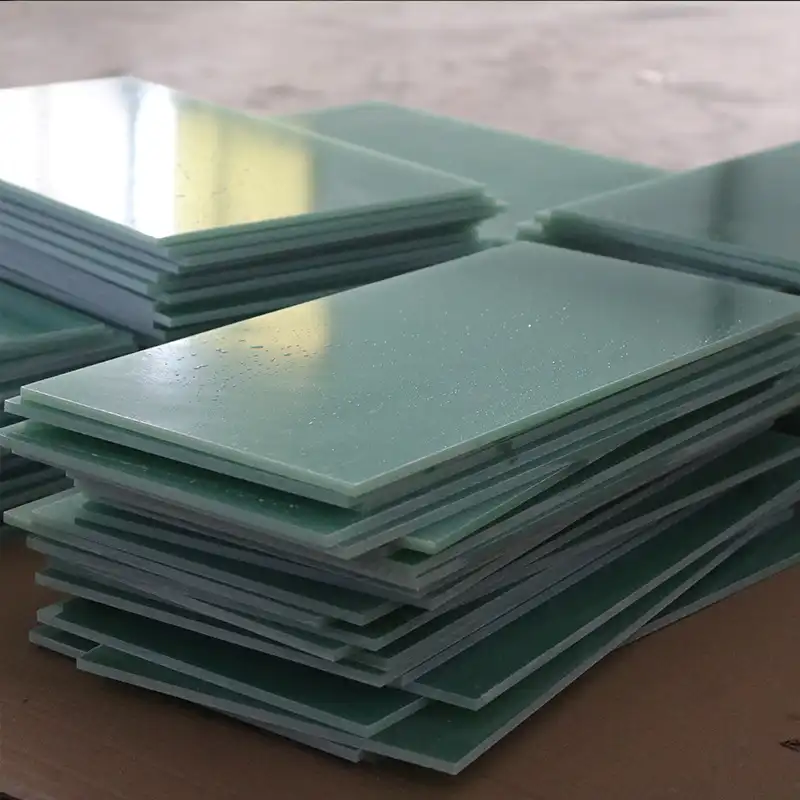

Modern train transit systems depend on G10 epoxy board, which is made of fiberglass cloth and epoxy resin and has a unique structure that makes it work exceptionally well. This high-pressure laminate material is perfect for rail transit uses that need great thermal protection, dielectric strength, and mechanical durability. G10 epoxy board is better at resisting chemicals and keeping electricity from flowing than older materials. It is now required for modern train infrastructure and rolling stock manufacturing processes to make sure safety, dependability, and operating efficiency.

Understanding G10 Epoxy Board: Properties and Technical Specifications

As a high-performance composite material, G10 epoxy board stands out. It is made through an exact production process that mixes continuous fiberglass cloth with epoxy resin under controlled heat and pressure. Using this method to make something makes a laminated structure that is very consistent and performs well in a wide range of operating situations.

Material Composition and Structure

G10 epoxy board is made up of a carefully balanced mix of thermosetting epoxy binder and fiberglass that strengthens it. The continuous fiberglass cloth gives the material great tensile strength and dimensional stability, and the epoxy glue system makes it stick better, fight chemicals better, and insulate electricity better. When you put these two things together, you get a material that keeps its shape under mechanical stress and works reliably electrically in harsh transportation settings.

Key Technical Properties

When looking at G10 epoxy board for use in train travel, there are a few important technical details that should be kept in mind. The material has great heat performance; it can withstand temperatures up to 180°C for short periods of time and 130°C for long periods of time. Its dielectric strength is usually higher than 15 kV/mm, which makes it perfect for electrical insulation jobs where safety is very important.

Flexural strength values for G10 epoxy board range from 300 to 450 MPa, which gives structural stability needed for parts that are vibrating and being loaded and unloaded quickly. It also doesn't absorb much water—less than 0.5%—so its dimensions stay stable even when the humidity changes, which is common in rail transit operations.

Comparative Material Analysis

In train transit uses, G10 epoxy board is clearly better than other materials such as FR4, phenolic laminates, and aluminum composites. FR4 and G10 have similar electrical properties, but G10 is stronger and more resistant to chemicals like cleaning fluids and environmental pollutants. While phenolic materials may be cheaper, they don't have the same level of temperature stability or electrical performance as G10.

Critical Applications of G10 Epoxy Board in Rail Transit

Rail transit systems depend on G10 epoxy board for many important tasks where failure of the material could affect safety or the speed of operations. Because this material is so flexible, it can be used in both electrical and mechanical parts of current train cars and infrastructure.

Electrical System Applications

G10 epoxy board is the best material for the base of printed circuit boards that handle important functions in train transit electrical systems, like traction control, braking systems, and passenger safety equipment. The material is very good at blocking electrical current that isn't supposed to flow, and it stays stable at room temperature even when electrical loads and weather factors cause temperature changes.

In addition to insulation barriers, another important use for G10 epoxy board is as a barrier between high-voltage parts and systems nearby. These barriers have to keep their dielectric qualities throughout the life of the car while also being able to handle the mechanical vibrations and temperature changes that happen during rail transit operations.

Structural and Mechanical Components

G10 epoxy board is useful for building structures inside train cars because it is very strong mechanically. The material can keep its shape under stress and provide electrical insulation where it's needed, which makes it useful for mounting brackets, equipment housings, and mechanical spacers.

During normal operation, rail transport systems are subject to a lot of shaking and shock loads. This is especially true in cities where trains speed up and slow down a lot. Under these conditions, G10 epoxy board components show great wear resistance, which means that they need less upkeep and are more reliable.

Customization Capabilities

In modern train transit projects, parts need to be custom made and have certain sizes, shapes, or performance qualities. CNC cutting works well with G10 epoxy board, which makes it possible to make complicated shapes with tight tolerances. Because it can be machined, makers can make personalized solutions that meet specific design needs while still using the material's natural performance benefits.

Advantages of Using G10 Epoxy Board in Rail Transit Industry

G10 epoxy board is being used in rail transit because it has many performance and cost benefits that directly help rail system managers and makers with their problems. These benefits include more than just the basic qualities of the material. They also include operational, upkeep, and lifetime cost factors.

Durability and Environmental Resistance

Rail transit settings are tough to work in because of things like high temperatures, water damage, chemical contamination, and motor stress. G10 epoxy board works great in these tough situations because it doesn't break down easily in the environment. The material keeps its electrical and structural features even when it comes into contact with cleaning chemicals, hydraulic fluids, and air pollutants that are common in rail operations.

A resistance to moisture is especially useful in rail uses where equipment may be subject to weather or cleaning methods. When exposed to wetness, some materials may delaminate or lose their power. G10 epoxy board, on the other hand, keeps its shape and performance over long periods of time.

Electrical Safety Enhancement

Electrical safety is very important in train transit systems because there are high voltages and currents running through the whole car. Because it is a good insulator and doesn't spark, G10 epoxy board helps make electrical safety better. These traits help keep electricity problems from happening that could cause service interruptions or safety risks.

Because the material's electrical performance stays the same across its practical temperature range, safety barriers and insulation parts keep working well no matter the temperature or load on the electrical system. This dependability lowers the chance of electrical problems and helps meet strict safety standards for train travel.

Economic Benefits

When it comes to buying things, G10 epoxy board has strong economic benefits that help make building and running a rail transit system more affordable. The competitive price structure of the material makes it possible to buy in bulk, which lowers the cost of each component while keeping performance standards.

The economy will gain in the long run because upkeep costs will go down and parts will last longer. Because G10 epoxy board is durable, it doesn't need to be replaced as often, which saves money on both the materials and work needed to repair parts. The material's dependability also helps make systems more available and reduces working interruptions.

Regulatory Compliance

Rail transit systems have to follow many safety and environmental rules that are different depending on the area and the type of system being used. G10 epoxy board materials come with standards like UL recognition, RoHS compliance, and railway-specific approvals that make it easier to follow the rules without affecting performance.

These licenses give procurement managers faith that the materials they choose will meet government standards and help with the project approval process. Having approved materials on hand also makes it easier to meet paperwork needs and lowers project risks related to compliance.

How to Choose the Right G10 Epoxy Board Supplier for Rail Transit Projects?

Picking the right source for G10 epoxy board materials requires a thorough analysis of many aspects that go beyond just price. Because train transit uses are so complicated and safety-critical, they need providers who can meet strict quality, delivery, and technical standards.

Manufacturing Capabilities and Quality Systems

Reliable G10 epoxy board sources keep up-to-date production techniques that make sure the material properties and dimensions stay the same. Quality management systems that are approved to ISO 9001 or a similar standard make sure that the right rules and paperwork are kept in place during the manufacturing process. For train transit applications, you might need extra certifications like ISO/TS 22163 for railway uses.

Standardized test methods should be used to make sure that the manufacturing facilities have full testing facilities that check the qualities of materials. Suppliers should give specific material certificates that list the electrical, mechanical, and thermal properties of each production lot. This way, quality can be checked and materials can be tracked all the way through the supply chain.

Technical Support and Customization Services

A lot of the time, rail transit projects need expert help with choosing materials, application engineering, and special manufacturing. Suppliers with expert teams that are full of experience can help you find the best material specs for your needs while still meeting all the necessary standards.

Suppliers can deliver parts that exactly meet the needs of a project by offering customization options such as precise cutting, custom sizes, and specialized surface treatments. These services make buying easier while making sure that things fit and work right in important situations.

Supply Chain Reliability

Rail transport projects have tight schedules that need reliable material supply to avoid delays that cost a lot of money. Suppliers should show that they can handle the supply chain well by keeping enough product on hand, offering more than one way to get goods, and planning for what to do if something goes wrong.

Being close to the site of a project can help with shipping times, transportation costs, and how quickly expert support can respond. But sellers should find a mix between what's available locally and what can be sourced globally to make sure materials are always available, no matter what the market is doing.

Procurement Guide: Ordering G10 Epoxy Boards for Rail Transit Applications

To successfully buy G10 epoxy board materials, you need to plan ahead and be clear about the technical requirements so that the materials you receive meet your needs and are supplied on time and at the lowest cost.

Technical Specification Development

Getting the right materials starts with having accurate technical specs. Dimensional requirements with acceptable ranges, electrical properties like dielectric strength and volume resistivity, mechanical properties like flexural and compressive strength, and thermal characteristics spanning working temperature ranges are some of the most important specs.

It is important to be clear about material certifications and compliance requirements so that supplied materials meet safety and legal standards. At the start of the buying process, it should be made clear what kinds of paperwork are needed, such as material certificates, test results, and information on how to track the goods.

Strategic Sourcing Approaches

Buying in bulk can save you a lot of money because the seller may offer better deals and discounts for larger orders. But procurement managers have to weigh the cost saves against the costs of keeping stockpiles and the length of time that materials will last. Strategic relationships with qualified sellers can give you better prices and faster access to goods when demand is high.

Multiple sourcing methods lower the risks in the supply chain by giving you more than one source for important products. To make sure there are backup plans ready when they are needed, qualified supply networks should be built and kept up to date.

Quality Assurance and Risk Management

Before being added to inventory, incoming material inspection processes should make sure that given materials meet certain requirements. Critical qualities should be checked using the right testing methods, especially in safety-critical situations where a failure of the material could have very bad results.

Systems that keep an eye on suppliers' work should keep track of how well they deliver, measure quality, and fix technology problems. Regular checks of suppliers can make sure that quality standards are still being met and find ways to make things better.

To avoid delays and keep inventory costs as low as possible, lead time management involves coordinating project schedules with the supply of materials. Just-in-time delivery methods can cut down on the need for inventory, but they need dependable providers and correct predictions of what customers will want.

Conclusion

Because it has such great electrical, mechanical, and thermal qualities, G10 epoxy board has become an important material for rail transit uses. The material is very useful for both electrical shielding and construction purposes because it can work reliably in harsh conditions. To make execution work, you need to carefully choose your suppliers, be clear on the technical requirements, and use strategic buying methods that balance performance needs with cost goals. As train transit systems continue to get more electric and automated, G10 epoxy board will stay an important part of making sure that transportation is safe, reliable, and efficient.

FAQ

What makes G10 epoxy board suitable for rail transit applications?

G10 epoxy board is very good at keeping electricity from flowing through it, and it is also very strong and stable at high temperatures. It can stand up to water, chemicals, and changes in temperature, which makes it perfect for harsh settings like rail transit systems, where safety and dependability are very important.

How does G10 epoxy board compare to FR4 in rail applications?

Both FR4 and G10 epoxy board are good for electrical purposes, but G10 epoxy board is stronger and more resistant to chemicals than FR4. This makes G10 a better choice for structure uses and places where it will be exposed to cleaning agents or environmental pollutants.

What certifications should I look for when purchasing G10 epoxy board for rail projects?

Look for materials that have been approved by UL, RoHS, and railway-specific standards like EN 45545 for fire behavior. ISO 9001-certified suppliers guarantee consistent quality control, and ISO/TS 22163-certified suppliers show they know a lot about the railway business.

Partner with J&Q for Premium G10 Epoxy Board Solutions

J&Q has been making and selling high-quality insulation materials for more than 20 years. They offer premium G10 epoxy board options that are perfect for rail transit uses. Because we have a lot of experience with foreign trade and a wide range of transportation skills, we can make sure that engineering managers and technical teams have a smooth procurement process. We provide materials that meet the high standards of current train systems thanks to our strict quality controls, UL/RoHS compliance, and custom machining services. Our dedicated technical support team works closely with clients to make sure that the material specs are optimized, and our combined transportation network makes sure that deliveries happen on time. Get in touch with our knowledgeable staff at info@jhd-material.com to talk about your G10 epoxy board needs and find out why top rail transit makers choose J&Q as their go-to G10 epoxy board provider.

References

Smith, A. and Johnson, B. "Advanced Composite Materials in Railway Applications: Performance and Safety Considerations." International Journal of Railway Technology, 2023.

Chen, L. "Electrical Insulation Systems for Modern Rail Transit: Material Selection and Design Guidelines." Railway Engineering Quarterly, 2022.

Williams, R. et al. "Thermal Management in Electric Rail Vehicles: Material Solutions for Enhanced Performance." Transportation Materials Review, 2023.

Rodriguez, M. "Quality Assurance in Railway Component Manufacturing: Standards and Best Practices." Rail Industry Standards Journal, 2022.

Thompson, K. "Lifecycle Cost Analysis of Insulation Materials in Rail Transit Applications." Economic Transportation Review, 2023.

Anderson, P. and Lee, S. "Fire Safety and Material Performance in Rail Vehicle Design: Regulatory Compliance and Testing." Railway Safety Engineering, 2022.