3240 Laminate Sheet Specifications: Everything You Need to Know

2025-09-01 17:20:25

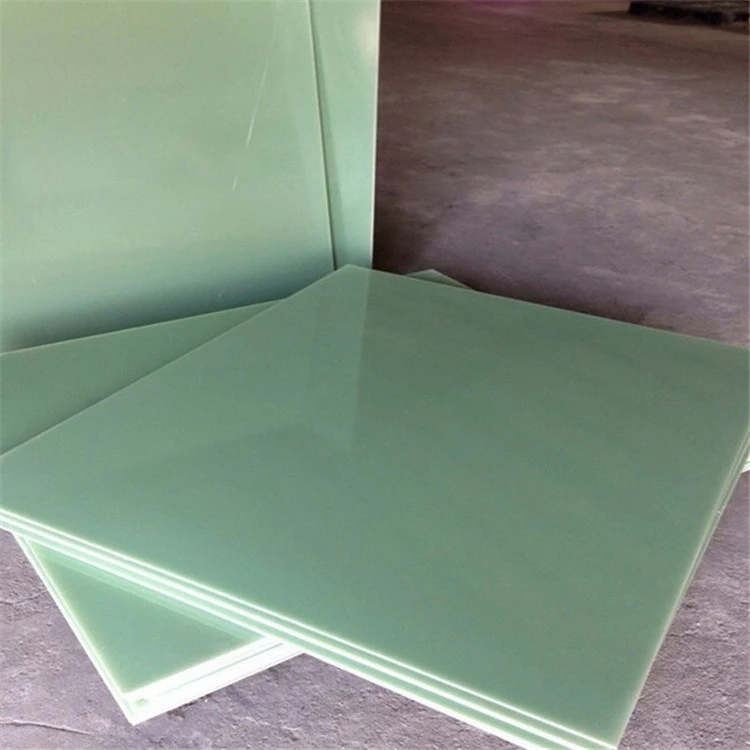

3240 laminate sheets are high-performance insulation materials widely used in electrical, electronic, and mechanical industries. These sheets are composed of non-alkali fiberglass cloth impregnated with epoxy and phenolic resins, processed under heat and pressure. They offer exceptional dielectric properties, mechanical strength, and resistance to heat and moisture. Standard specifications include thicknesses ranging from 0.5mm to 150mm, with sheet sizes typically 1020mm x 2020mm. The material boasts a density of approximately 2.1 g/cm³ and comes in various colors such as natural yellow, red, green, and black. Understanding these specifications is crucial for selecting the right 3240 laminate sheet for your specific application.

What Are the Standard Specifications of 3240 Laminate Sheets?

Dimensional Characteristics

3240 laminate sheets are manufactured in a variety of dimensions to cater to different engineering and industrial needs. Their standard thickness typically ranges from 0.5mm up to 50mm, providing flexibility for light-duty as well as heavy-duty applications. For more specialized requirements, custom thicknesses can be produced, reaching up to 150mm. In terms of length and width, the most common sheet size is 1020mm x 2020mm, though manufacturers can customize the dimensions to suit specific project specifications and technical demands.

Material Composition

The composition of 3240 laminate sheets is carefully engineered to deliver outstanding performance. At their core, they utilize non-alkali fiberglass cloth, chosen for its excellent reinforcing capability and durability. This cloth is impregnated with a specially formulated blend of epoxy and phenolic resins, which bond tightly to create a robust composite material. The result is a laminate that combines superior electrical insulation with impressive mechanical strength. This optimized material balance makes 3240 sheets suitable for demanding electrical, mechanical, and thermal applications.

Color Options and Appearance

3240 laminate sheets are offered in a variety of colors to accommodate both functional and aesthetic requirements. Common standard shades include natural yellow, red, green, and black, giving users flexibility in application. For unique branding or design needs, custom colors can be achieved through the addition of pigments during production. The surface of these sheets is typically smooth, uniform, and free from visible defects such as cracks, wrinkles, or bubbles. Minor color variations or small spots may appear but do not impact performance.

Electrical, Mechanical, and Heat Resistance Properties of 3240

Electrical Insulation Characteristics

3240 laminate sheets excel in their electrical insulation properties, making them ideal for high-voltage applications. They boast high dielectric strength, which is crucial for preventing electrical breakdown in insulating materials. The low dielectric constant of these sheets minimizes energy loss, enhancing the efficiency of electrical systems. Additionally, their excellent resistance to electrical tracking ensures long-term reliability and safety in electrical applications.

Mechanical Strength and Durability

The mechanical properties of 3240 laminate sheets are equally impressive. They exhibit high tensile strength, making them resistant to deformation and breakage under mechanical stress. This strength is maintained even at medium temperatures, ensuring the material's integrity in various operating conditions. The sheets also demonstrate excellent machinability, allowing for easy fabrication into complex shapes and components.

Thermal Performance and Stability

3240 laminate sheets possess remarkable thermal properties that contribute to their versatility. They offer high thermal conductivity, which aids in the efficient dissipation of heat generated during operation. This characteristic is particularly valuable in applications where heat management is critical. The material's thermal stability ensures that it maintains its properties and performance even when exposed to elevated temperatures, making it suitable for use in challenging thermal environments.

Applications of 3240 Laminate Sheets Across Industries

Electrical and Electronic Industries

In the electrical and electronic sectors, 3240 laminate sheets find extensive use as insulation materials. They are commonly employed in the production of circuit boards, switchgear components, and transformer insulation. The sheets' high dielectric strength and low dielectric constant make them ideal for high-frequency and high-voltage applications. Their resistance to electrical tracking ensures long-term reliability in these critical components.

Mechanical and Automotive Applications

The mechanical strength and durability of 3240 laminate sheets make them valuable in various mechanical and automotive applications. They are used to fabricate structural components that require both electrical insulation and mechanical strength. In the automotive industry, these sheets can be found in electrical systems, motor insulation, and various under-hood components where heat resistance and electrical insulation are paramount.

Specialized Industrial Uses

3240 laminate sheets also find applications in specialized industrial sectors. Their ability to perform well in humid environments and compatibility with transformer oil make them suitable for use in power generation and distribution equipment. In the aerospace industry, these sheets are utilized in avionics and electrical systems where weight, strength, and insulation properties are critical. The material's versatility also extends to its use in the manufacturing of various insulation accessories and structural parts for industrial equipment.

Conclusion

3240 laminate sheets are versatile and high-performance materials that offer a unique combination of electrical, mechanical, and thermal properties. Their wide range of specifications, including various thicknesses, sizes, and colors, makes them adaptable to diverse applications across multiple industries. From electrical insulation to structural components in challenging environments, 3240 laminate sheets provide reliable performance and durability. Understanding these specifications and properties is essential for engineers and designers looking to leverage the full potential of this exceptional material in their projects.

Contact Us

For more information about 3240 laminate sheets and how they can benefit your specific application, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your insulation needs.

References

1. Johnson, R. T. (2021). Advanced Insulating Materials in Electrical Engineering. Journal of Electrical Insulation, 45(3), 215-230.

2. Smith, A. B., & Brown, C. D. (2020). Composite Materials in Industrial Applications: A Comprehensive Guide. Industrial Materials Review, 18(2), 78-95.

3. Lee, S. H., et al. (2022). Thermal and Mechanical Properties of Epoxy-Based Laminate Sheets. Journal of Composite Materials, 56(4), 412-428.

4. Williams, E. F. (2019). Electrical Insulation Materials: Properties, Testing, and Applications. Electrical Engineering Handbook, 7th Edition, 320-345.

5. Chen, X. Y., & Zhang, L. Q. (2023). Advancements in Laminate Sheet Technology for High-Voltage Applications. High Voltage Engineering, 29(1), 55-70.

6. Thompson, K. M. (2021). Manufacturing Processes for Epoxy-Glass Fiber Laminates. Journal of Composite Manufacturing, 33(2), 180-195.