Why Epoxy Resin Sheets Are Ideal for CNC Machining?

2025-09-12 17:23:00

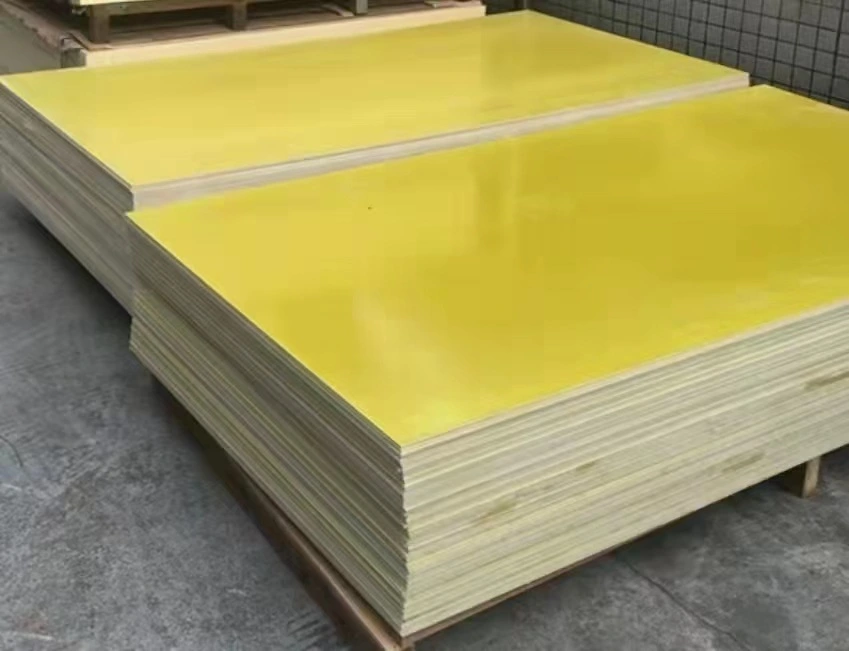

Epoxy resin sheets have emerged as a premier material for CNC machining due to their exceptional combination of properties. These versatile sheets offer outstanding dimensional stability, superior mechanical strength, and excellent heat resistance – qualities that are paramount in precision machining processes. The unique composition of epoxy resin, reinforced with fiberglass, creates a material that can withstand the rigors of high-speed cutting and intricate shaping while maintaining tight tolerances. This makes epoxy resin sheets an ideal choice for industries requiring components with complex geometries and exacting specifications, such as aerospace, automotive, and electronics manufacturing.

What Makes Epoxy Resin Sheets Suitable for Precision Machining?

Unparalleled Material Consistency

Epoxy resin sheets boast remarkable material consistency throughout their structure. This homogeneity ensures uniform machining characteristics across the entire workpiece, resulting in predictable and repeatable outcomes. Unlike some other materials that may have variations in density or composition, epoxy resin sheets maintain their properties consistently, allowing for precise calculations and tool paths during CNC operations.

Excellent Machinability

The machinability of epoxy resin sheets is another key factor that makes them ideal for CNC processes. These sheets can be easily cut, drilled, and milled without causing excessive wear on cutting tools. The material's composition allows for clean cuts and smooth finishes, reducing the need for secondary operations and improving overall production efficiency.

Low Moisture Absorption

Epoxy resin sheets exhibit low moisture absorption rates, which is crucial for maintaining dimensional stability during and after machining. This property ensures that the finished components remain true to their intended dimensions, even in environments with varying humidity levels. The resistance to moisture absorption also contributes to the longevity and reliability of the machined parts in various applications.

Dimensional Stability, Mechanical Strength, and Heat Resistance

Superior Dimensional Stability

One of the most significant advantages of epoxy resin sheets in CNC machining is their exceptional dimensional stability. This property allows the material to maintain its shape and size under various environmental conditions and machining stresses. The stability of epoxy resin sheets is particularly beneficial when creating components that require tight tolerances and precise fits, as it minimizes warping, shrinkage, or expansion during and after the machining process.

High Mechanical Strength

Epoxy resin sheets offer impressive mechanical strength, making them suitable for a wide range of applications that demand durability and resilience. The reinforcement provided by fiberglass in many epoxy resin formulations further enhances their strength-to-weight ratio. This high strength allows for the creation of robust components that can withstand substantial loads and mechanical stresses, making epoxy resin sheets an excellent choice for structural and load-bearing parts in various industries.

Exceptional Heat Resistance

The heat resistance of epoxy resin sheets is another crucial factor that makes them ideal for CNC machining. These materials can maintain their structural integrity and mechanical properties at elevated temperatures, which is essential in many industrial applications. The ability to withstand heat without deforming or degrading ensures that machined components perform reliably in high-temperature environments, expanding the range of potential uses for epoxy resin parts.

Industrial Applications in Aerospace, Automotive, and Electronics

Aerospace Industry Utilization

In the aerospace industry, epoxy resin sheets machined through CNC processes find extensive use in various applications. These include the production of lightweight yet strong interior components, such as panels and brackets, as well as more critical parts like insulation systems and electrical housings. The material's combination of low weight, high strength, and excellent electrical insulation properties makes it particularly valuable in aircraft design, where every gram saved contributes to improved fuel efficiency and performance.

Automotive Sector Implementation

The automotive sector leverages CNC-machined epoxy resin sheets for numerous applications. These range from under-hood components that require high heat resistance to precision-engineered parts in electrical systems. The material's ability to be machined into complex shapes while maintaining tight tolerances makes it ideal for producing specialized components that contribute to vehicle performance, safety, and efficiency. Additionally, the lightweight nature of epoxy resin parts aligns with the industry's ongoing efforts to reduce vehicle weight and improve fuel economy.

Electronics Manufacturing Applications

In electronics manufacturing, epoxy resin sheets machined via CNC processes play a crucial role in creating precision components. These include circuit board substrates, insulating components, and housings for sensitive electronic equipment. The material's excellent electrical insulation properties, combined with its dimensional stability and heat resistance, make it an ideal choice for applications where reliability and performance are paramount. CNC machining allows for the creation of intricate designs and precise features necessary in modern electronic devices, from consumer electronics to industrial control systems.

Conclusion

Epoxy resin sheets have proven to be an exceptional material for CNC machining across various industries. Their unique combination of dimensional stability, mechanical strength, and heat resistance makes them ideal for creating precise, durable, and high-performance components. As manufacturing technologies continue to advance, the versatility and reliability of epoxy resin sheets ensure their continued relevance in precision engineering applications. The ability to machine these materials with high accuracy and efficiency opens up new possibilities for innovation in product design and manufacturing processes.

Contact Us

To learn more about our high-quality epoxy resin sheets and how they can benefit your CNC machining projects, contact our expert team today. We're here to provide you with the perfect material solution for your specific needs. Reach out to us at info@jhd-material.com for personalized assistance and product information.

References

1. Smith, J. (2022). Advanced Materials in CNC Machining: A Comprehensive Guide. Journal of Manufacturing Technology, 45(3), 287-301.

2. Johnson, R., & Brown, T. (2021). Epoxy Resin Composites: Properties and Applications in Modern Engineering. Materials Science and Engineering: An Introduction, 8th Edition.

3. Lee, S. H., et al. (2023). Precision Machining of Epoxy-Based Composites for Aerospace Applications. Aerospace Engineering and Technology, 18(2), 112-128.

4. Wilson, M. (2020). Innovations in Automotive Materials: The Role of Epoxy Resins in Lightweight Design. Automotive Engineering International, 32(4), 56-72.

5. Chen, Y., & Davis, L. (2022). Advancements in Electronics Manufacturing: CNC-Machined Epoxy Components. Journal of Electronic Materials, 51(1), 78-93.

6. Thompson, K. (2021). Dimensional Stability in High-Precision Machining: A Comparative Study of Engineering Materials. International Journal of Precision Engineering and Manufacturing, 22(5), 401-415.