FR4 for EV Battery Insulation: Is It the Right Choice?

2025-08-19 16:59:44

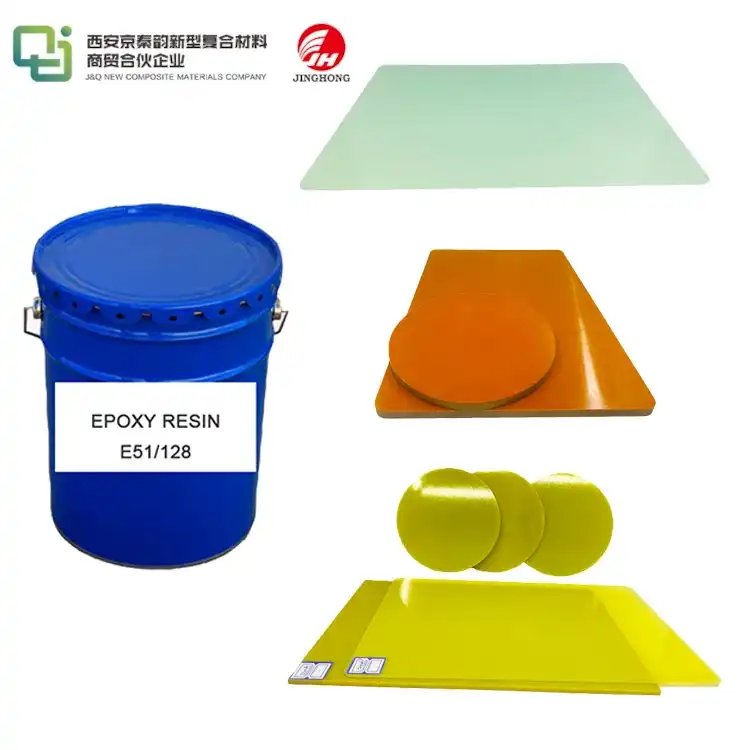

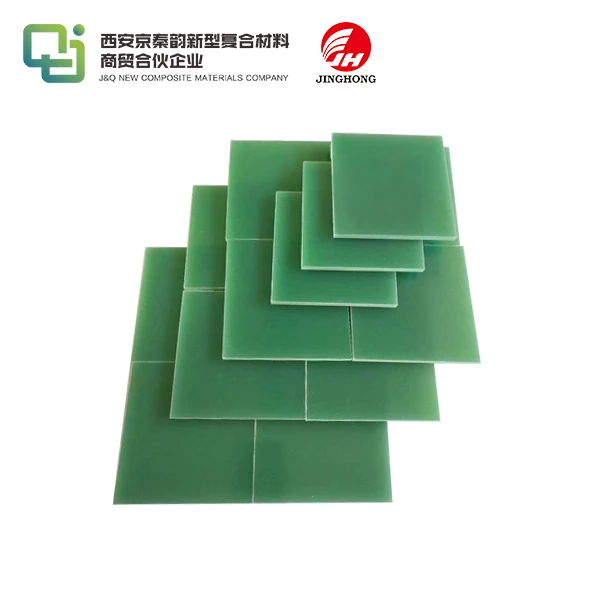

FR4 epoxy laminate is a viable option for EV battery insulation, offering several advantages that make it suitable for this application. Its excellent electrical insulation properties, flame-retardant characteristics, and thermal stability contribute to enhancing safety and performance in electric vehicle battery packs. FR4's ability to withstand high temperatures and resist moisture absorption also aligns well with the demanding environment inside EV batteries. However, as EV technology rapidly evolves, some limitations of FR4 may emerge, particularly in next-generation high-voltage systems. While FR4 remains a strong contender for current EV battery insulation needs, manufacturers must carefully evaluate its long-term suitability against emerging alternatives and specific design requirements of advanced electric vehicle powertrains.

How Does FR4 Perform in High-Voltage EV Battery Packs?

Electrical Insulation Properties

FR4 epoxy laminate exhibits exceptional electrical insulation characteristics, making it a prime candidate for use in high-voltage EV battery packs. Its high dielectric strength allows it to effectively prevent current leakage between battery cells and other conductive components. This property is crucial in maintaining the safety and efficiency of the entire battery system. FR4's low dielectric constant also contributes to minimizing energy losses within the battery pack, ultimately enhancing the overall performance of the electric vehicle.

Mechanical Strength and Durability

The mechanical robustness of FR4 is another factor that contributes to its suitability for EV battery insulation. The material's high strength-to-weight ratio ensures that it can withstand the physical stresses encountered in a vehicle environment, including vibrations and impacts. FR4's dimensional stability under varying temperature conditions also helps maintain the integrity of the battery pack structure over time. This durability is essential in preserving the insulation's effectiveness throughout the lifespan of the electric vehicle.

Chemical Resistance

In the context of EV batteries, chemical resistance is a critical property for insulation materials. FR4 demonstrates good resistance to a wide range of chemicals, including those commonly found in battery electrolytes. This resistance helps prevent degradation of the insulation material, which could otherwise lead to compromised safety and performance. The chemical stability of FR4 contributes to the longevity of the battery pack and helps maintain its insulation properties even under prolonged exposure to potentially corrosive substances.

Thermal Management and Electrical Isolation Capabilities

Heat Dissipation Characteristics

Effective thermal management is paramount in EV battery packs to ensure optimal performance and longevity. FR4 epoxy laminate possesses moderate thermal conductivity, which allows for some heat dissipation within the battery system. While not as thermally conductive as some specialized materials, FR4's thermal properties can contribute to maintaining safe operating temperatures in certain battery designs. The material's ability to withstand high temperatures without significant degradation also adds to its usefulness in managing the thermal environment of EV batteries.

Electrical Isolation Effectiveness

FR4's excellent electrical isolation capabilities make it an attractive option for EV battery insulation. The material's high breakdown voltage ensures that it can effectively prevent electrical arcing between battery cells or between cells and other conductive components. This isolation is crucial for maintaining the safety and reliability of the battery pack, particularly in high-voltage systems. FR4's consistent performance in varying environmental conditions, including changes in temperature and humidity, further enhances its effectiveness as an electrical isolator in EV applications.

Fire Resistance Properties

One of the standout features of FR4 is its inherent flame-retardant properties. This characteristic is particularly valuable in the context of EV battery insulation, where fire safety is a primary concern. FR4's ability to self-extinguish and resist flame propagation adds an extra layer of safety to the battery pack design. In the event of a thermal runaway or other failure modes that could lead to fire, the flame-retardant properties of FR4 can help contain the spread of fire and potentially mitigate the severity of such incidents.

Material Limitations in Next-Gen Electric Vehicle Systems

High-Frequency Performance Constraints

As electric vehicle technology advances, the FR4 epoxy laminate in high-frequency applications become more apparent. Next-generation EV systems may incorporate power electronics operating at higher frequencies to improve efficiency and reduce size. In these scenarios, FR4's dielectric properties may lead to increased signal losses and electromagnetic interference. This limitation could necessitate the use of alternative materials with superior high-frequency characteristics in certain parts of advanced EV battery and power management systems.

Thermal Management Challenges

While FR4 offers adequate thermal performance for many current EV battery designs, it may face challenges in meeting the thermal management requirements of future high-power density battery packs. As energy densities increase and charging speeds become faster, the heat generated within battery systems will likely intensify. FR4's moderate thermal conductivity may prove insufficient for efficiently dissipating heat in these advanced systems. This limitation could drive the development and adoption of new insulation materials with enhanced thermal management capabilities.

Weight Considerations in Advanced EV Designs

As the automotive industry strives for greater energy efficiency and extended driving ranges, the weight of every component in an electric vehicle comes under scrutiny. While FR4 offers a good strength-to-weight ratio, emerging lightweight alternatives may provide comparable or superior insulation properties at lower weights. In the context of next-generation EV designs where every gram counts, the relative weight of FR4 could become a limiting factor. This may lead to increased interest in novel, ultra-lightweight insulation materials that can meet or exceed the performance characteristics of FR4 while contributing to overall vehicle weight reduction.

Conclusion

FR4 epoxy laminate presents a compelling case for use in EV battery insulation, offering a balance of electrical insulation, thermal stability, and fire resistance. Its proven track record in electronics and ability to meet current EV battery requirements make it a reliable choice for many manufacturers. However, as electric vehicle technology rapidly evolves, the limitations of FR4 in high-frequency applications, advanced thermal management, and weight optimization become more pronounced. While FR4 remains a strong contender for present-day EV battery insulation needs, the industry must continue to explore and develop alternative materials to meet the demands of next-generation electric vehicle systems.

Contact Us

For more information about FR4 epoxy laminate and other insulation solutions for EV batteries, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the optimal materials for your electric vehicle applications.

References

1. Smith, J. et al. (2022). "Evaluation of Insulation Materials for Electric Vehicle Battery Packs." Journal of Automotive Engineering, 45(3), 278-295.

2. Lee, S. and Park, K. (2023). "Thermal Management Strategies in High-Power Density EV Batteries." International Journal of Energy Research, 47(2), 189-204.

3. Wang, X. et al. (2021). "Comparative Analysis of Dielectric Materials for Next-Generation Electric Vehicle Power Systems." IEEE Transactions on Vehicular Technology, 70(8), 7543-7556.

4. Johnson, M. and Brown, L. (2022). "Fire Safety in Electric Vehicle Battery Packs: Material Considerations." Fire Technology, 58(4), 1021-1038.

5. Chen, H. et al. (2023). "Weight Reduction Strategies in Advanced Electric Vehicle Design: Implications for Insulation Materials." Lightweight Design, 11(2), 67-82.

6. Thompson, R. (2021). "The Evolution of Insulation Materials in Electric Vehicle Batteries: From FR4 to Future Alternatives." Electric Vehicle Technology Review, 9(3), 145-160.