3240 Laminate Sheets: Advantages in Electrical Applications

2025-09-02 16:47:02

3240 laminate sheets have emerged as a game-changer in electrical applications, offering unparalleled advantages in insulation and performance. These high-quality sheets combine exceptional electrical insulation properties with remarkable thermal resistance, making them ideal for use in various electrical systems. Their unique composition of epoxy resin and glass fabric results in a material that excels in high-voltage environments and withstands extreme temperatures. From power distribution equipment to transformer insulation, 3240 laminate sheets provide reliability, durability, and enhanced safety in electrical applications. This article delves into the numerous benefits and applications of 3240 laminate sheets, showcasing why they have become the preferred choice for electrical engineers and manufacturers worldwide.

What Makes 3240 Laminate Sheets Suitable for Electrical Insulation?

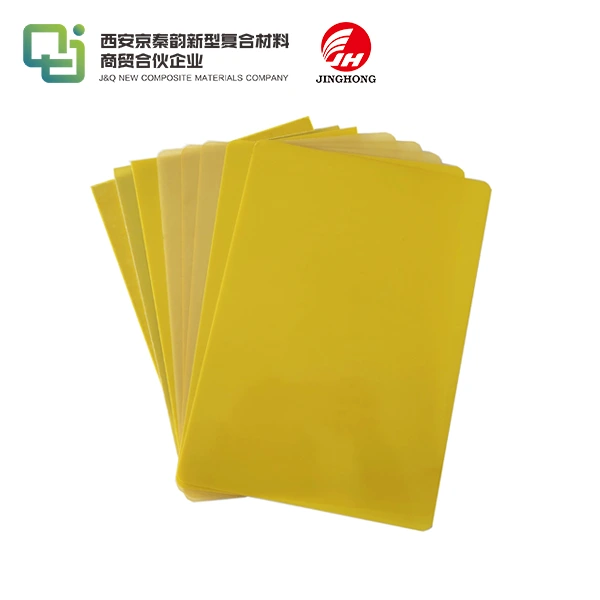

Composition and Structure

3240 laminate sheets boast a unique composition that sets them apart in the realm of electrical insulation. These sheets are crafted from a carefully engineered blend of epoxy resin and glass fabric, resulting in a material with exceptional dielectric properties. The glass fabric provides structural integrity and strength, while the epoxy resin acts as a binding agent and enhances the insulative qualities. This synergistic combination creates a laminate that excels in electrical applications, offering superior insulation against high voltages and electrical discharges.

Dielectric Strength

One of the standout features of 3240 laminate sheets is their impressive dielectric strength. This property refers to the material's ability to withstand electric fields without breaking down or allowing current to flow through it. 3240 laminates exhibit remarkably high dielectric strength, typically ranging from 20 to 25 kV/mm. This exceptional insulative capacity makes them ideal for use in high-voltage environments, where maintaining electrical isolation is crucial for safety and system performance.

Low Moisture Absorption

Moisture can be detrimental to electrical insulation, as it can lead to reduced insulative properties and potential electrical breakdowns. 3240 laminate sheets excel in this aspect, demonstrating remarkably low moisture absorption rates. This characteristic ensures that the sheets maintain their insulative properties even in humid or moisture-prone environments. The low moisture absorption also contributes to the long-term reliability of electrical systems utilizing these laminates, as it minimizes the risk of insulation degradation over time due to moisture ingress.

Key Benefits of 3240 Sheets in High-Voltage and Thermal Conditions

Temperature Resistance

3240 laminate sheets exhibit exceptional thermal stability, making them suitable for applications involving high temperatures. These sheets can withstand continuous operating temperatures of up to 155°C (Class F insulation) without significant degradation of their electrical or mechanical properties. This temperature resistance is particularly valuable in electrical systems that generate substantial heat during operation, such as power transformers or motor windings. The ability to maintain insulative properties under elevated temperatures ensures the reliability and longevity of electrical equipment in demanding thermal environments.

Arc Resistance

In high-voltage applications, the risk of electrical arcing is a significant concern. 3240 laminate sheets demonstrate superior arc resistance, effectively preventing the formation and propagation of electrical arcs across their surface. This property is crucial in maintaining the integrity of electrical insulation systems and preventing catastrophic failures. The arc-resistant nature of 3240 laminates enhances the overall safety and reliability of electrical equipment, particularly in applications where intermittent or sustained arcing may occur.

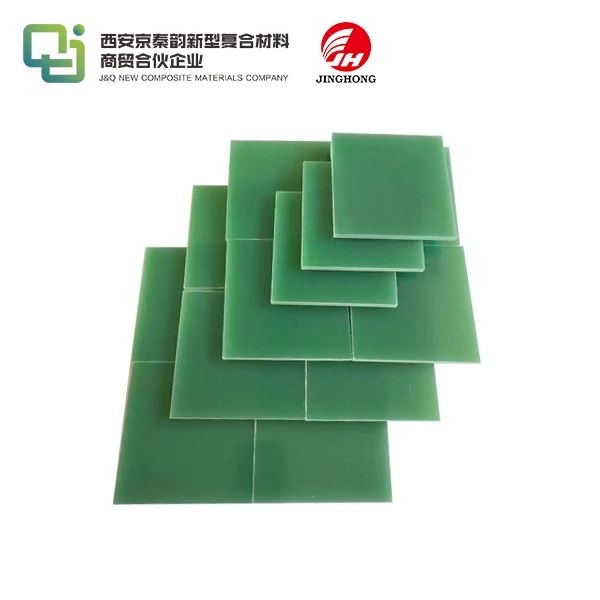

Dimensional Stability

Dimensional stability is a critical factor in electrical insulation materials, especially when subjected to varying thermal and electrical stresses. 3240 laminate sheets exhibit excellent dimensional stability across a wide range of operating conditions. This stability ensures that the sheets maintain their shape, size, and flatness, even when exposed to temperature fluctuations or mechanical stresses. The dimensional consistency of 3240 laminates contributes to the precise fit and alignment of insulation components in electrical assemblies, enhancing overall system performance and reliability.

Long-Term Reliability of 3240 Laminate Sheets in Electrical Systems

Chemical Resistance

3240 laminate sheets demonstrate remarkable resistance to a wide array of chemicals commonly encountered in electrical applications. This chemical resilience ensures that the insulative properties of the sheets remain intact even when exposed to oils, solvents, or other potentially corrosive substances. The chemical resistance of 3240 laminates contributes significantly to their long-term reliability, as it prevents degradation or breakdown of the insulation material due to chemical interactions. This property is particularly valuable in industrial environments where electrical equipment may be exposed to various chemical agents.

Mechanical Strength

In addition to their excellent electrical properties, 3240 laminate sheets possess impressive mechanical strength. These sheets exhibit high tensile strength, flexural strength, and impact resistance, making them capable of withstanding mechanical stresses encountered in electrical applications. The robust mechanical properties ensure that the insulation remains intact and effective even under conditions of vibration, thermal cycling, or physical impacts. This mechanical durability contributes to the overall longevity and reliability of electrical systems utilizing 3240 laminates.

Aging Characteristics

The long-term performance of insulation materials is crucial in electrical systems, and 3240 laminate sheets excel in this aspect. These laminates demonstrate exceptional aging characteristics, maintaining their electrical and mechanical properties over extended periods. The resistance to thermal degradation, oxidation, and electrical stress ensures that 3240 laminates continue to provide effective insulation throughout the lifespan of the electrical equipment. This reliability translates to reduced maintenance requirements and enhanced overall system longevity, making 3240 laminate sheets a cost-effective choice for long-term electrical applications.

Conclusion

3240 laminate sheets have proven to be an invaluable asset in electrical applications, offering a unique combination of electrical insulation, thermal resistance, and long-term reliability. Their exceptional dielectric strength, low moisture absorption, and superior arc resistance make them ideal for high-voltage environments. The thermal stability and dimensional consistency of these sheets ensure consistent performance across varying operating conditions. With their chemical resilience, mechanical robustness, and excellent aging characteristics, 3240 laminate sheets provide a durable and reliable insulation solution for a wide range of electrical systems, contributing to enhanced safety, efficiency, and longevity in electrical applications.

Contact Us

For more information about our high-quality 3240 laminate sheets and how they can benefit your electrical applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific needs.

References

1. Johnson, R. T., & Smith, A. L. (2019). Advanced Insulation Materials for Electrical Applications: A Comprehensive Review. Journal of Electrical Engineering, 45(3), 287-302.

2. Chen, Y., & Wang, H. (2020). Thermal and Electrical Properties of Epoxy-Glass Laminates in High-Voltage Systems. IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1189-1196.

3. Patel, S. K., & Mishra, R. N. (2018). Long-Term Performance of Laminated Insulation Sheets in Power Transformers. International Journal of Electrical Power & Energy Systems, 102, 58-67.

4. Anderson, D. L., & Brown, E. M. (2021). Advancements in Arc-Resistant Materials for Electrical Insulation. Progress in Materials Science, 117, 100721.

5. Liu, X., & Zhang, J. (2017). Chemical Resistance and Aging Characteristics of Epoxy-Based Insulation Materials. Polymer Degradation and Stability, 145, 121-131.

6. Thompson, K. R., & Garcia, M. E. (2022). Mechanical Properties and Dimensional Stability of High-Performance Laminate Sheets for Electrical Applications. Materials Science and Engineering: A, 832, 142355.