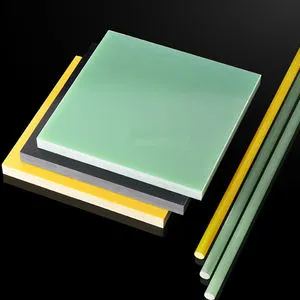

Can You Laser Cut FR4 Fiberglass Sheets?

2025-08-15 17:28:21

Yes, FR4 fiberglass sheets can be laser cut, but it's not without risks and challenges. While laser cutting offers precision and speed, the process can release harmful fumes and potentially damage the material. The glass fibers in FR4 sheets may cause rapid wear on laser optics, and the epoxy resin can produce toxic vapors when heated. Proper ventilation and safety measures are crucial. Alternative methods like CNC routing or water jet cutting are often preferred for working with FR4, especially for thicker sheets or when maintaining the material's electrical properties is essential. The choice of cutting method ultimately depends on the specific project requirements, available equipment, and safety considerations.

What Are the Risks of Laser Cutting Glass Epoxy Materials?

Material Degradation and Performance Impact

Laser cutting FR4 fiberglass sheets can lead to significant material degradation. The intense heat from the laser beam may alter the chemical structure of the epoxy resin, potentially compromising its electrical insulation properties. This degradation can result in reduced dielectric strength and increased conductivity along the cut edges, which is particularly problematic for electronic applications. Moreover, the heat-affected zone around the cut can experience delamination, where the layers of glass fabric and epoxy separate, weakening the overall structural integrity of the sheet.

Optical System Damage

The abrasive nature of glass fibers in FR4 sheets poses a substantial risk to laser cutting equipment. As the laser vaporizes the material, fine glass particles can become airborne and settle on the optical components of the laser system. Over time, these particles can scratch or cloud the lenses and mirrors, leading to reduced cutting efficiency and potentially costly repairs. The damage to optical systems can be particularly rapid and severe when cutting thicker FR4 sheets or performing extensive cutting operations.

Inconsistent Cut Quality

Achieving consistent cut quality across FR4 fiberglass sheets can be challenging due to the material's heterogeneous composition. The varying densities of glass fibers and epoxy resin can cause the laser beam to interact differently with different areas of the sheet. This inconsistency may result in rough edges, incomplete cuts, or areas of excessive melting. The presence of voids or impurities in the material can further exacerbate these issues, leading to unpredictable cutting results and potentially compromising the precision required for many electronic applications.

Smoke, Resin Vapors, and Ventilation Requirements

Toxic Fume Generation

The laser cutting process of FR4 fiberglass sheets generates a complex mixture of toxic fumes. As the epoxy resin is heated and vaporized, it releases volatile organic compounds (VOCs) and other harmful substances. These may include formaldehyde, styrene, and phenol derivatives, which are known respiratory irritants and potential carcinogens. The glass fibers, when heated to extreme temperatures, can also produce silica dust, presenting additional inhalation hazards. Proper understanding of these fume compositions is crucial for implementing effective safety measures and selecting appropriate filtration systems.

Advanced Ventilation Systems

To mitigate the risks associated with toxic fumes, specialized ventilation systems are indispensable when laser cutting FR4 fiberglass sheets. These systems should incorporate high-efficiency particulate air (HEPA) filters to capture fine glass particles and activated carbon filters to adsorb VOCs and other chemical vapors. The ventilation setup must ensure a negative pressure environment in the cutting area to prevent fume escape into surrounding workspaces. Additionally, the system should be designed with sufficient airflow capacity to handle the volume of fumes generated during peak cutting operations, with considerations for the size of the cutting area and the intensity of the laser cutting process.

Monitoring and Maintenance Protocols

Implementing rigorous monitoring and maintenance protocols is essential for ensuring the ongoing effectiveness of ventilation systems used in FR4 laser cutting operations. Regular air quality assessments should be conducted to verify that fume extraction is adequate and that exposure levels remain below established safety thresholds. Maintenance schedules must include frequent inspection and replacement of filters, as they can quickly become saturated with particulates and chemical contaminants. Monitoring should also extend to the laser cutting equipment itself, as buildup of debris on optical components can affect cutting performance and potentially increase fume generation. Establishing clear procedures for system checks, filter changes, and equipment cleaning is crucial for maintaining a safe and efficient working environment.

Safer Alternatives to Laser Cutting for Precision Work

CNC Routing Techniques

CNC routing presents a viable alternative to laser cutting for FR4 fiberglass sheets, offering precision without the associated fume hazards. This subtractive manufacturing process utilizes computer-controlled cutting tools to shape the material. CNC routing excels in maintaining the structural integrity of FR4 sheets, as it doesn't introduce the heat-affected zones typical of laser cutting. The process allows for intricate designs and can accommodate various thicknesses with minimal material waste. Advanced CNC systems can achieve tolerances comparable to laser cutting, making them suitable for high-precision electronic applications. However, tool wear can be significant due to the abrasive nature of glass fibers, necessitating frequent bit replacements and potentially increasing operational costs.

Water Jet Cutting Advantages

Water jet cutting offers another safe and effective method for processing FR4 fiberglass sheets. This technique uses a high-pressure stream of water, often mixed with abrasive particles, to cut through the material. The primary advantage of water jet cutting is its cold-cutting nature, which eliminates the risk of heat-induced material degradation and toxic fume generation. It's particularly adept at handling thicker FR4 sheets without compromising the material's electrical properties. Water jet cutting produces clean, precise edges with minimal delamination, making it ideal for applications requiring high-quality finishes. The process is versatile, allowing for complex shapes and patterns to be cut with ease. While initial equipment costs can be high, the method offers long-term benefits in terms of safety and material preservation.

Mechanical Punching and Die-Cutting

For high-volume production of standardized FR4 components, mechanical punching and die-cutting methods offer efficient alternatives to laser cutting. These processes use specialized tools to stamp or cut shapes from FR4 sheets with high precision and repeatability. Punching is particularly suitable for creating holes and simple geometric shapes, while die-cutting can produce more complex forms. Both methods are fast, cost-effective for large production runs, and don't generate hazardous fumes. They maintain the material's electrical properties and structural integrity, as there's no heat involved in the cutting process. However, the initial tooling costs can be significant, making these methods more economical for large-scale, repetitive production rather than prototyping or small batch work. The rigidity of the tooling also limits design flexibility compared to more versatile cutting methods.

Conclusion

While laser cutting FR4 fiberglass sheets is possible, it comes with significant challenges and risks. The potential for material degradation, equipment damage, and hazardous fume generation necessitates careful consideration of alternative methods. CNC routing, water jet cutting, and mechanical techniques offer safer, often more suitable options for processing FR4 sheets, especially in applications where maintaining the material's electrical properties is crucial. The choice of cutting method should be based on a thorough assessment of project requirements, safety considerations, and long-term operational costs. Prioritizing worker safety and environmental responsibility while achieving precise, high-quality results is paramount in FR4 sheet processing.

Contact Us

Ready to explore the best FR4 fiberglass sheet processing solutions for your project? Contact our experts at info@jhd-material.com for personalized advice and high-quality materials tailored to your specific needs.

References

1. Lau, J. H., & Lee, S. W. R. (2019). Chip Scale Package: Design, Materials, Processes, Reliability, and Applications. McGraw-Hill Education.

2. Coombs, C. F. (2008). Printed Circuits Handbook. McGraw-Hill Professional.

3. Jawaid, M., & Thariq, M. (Eds.). (2018). Sustainable Composites for Aerospace Applications. Woodhead Publishing.

4. Harper, C. A. (2004). Electronic Materials and Processes Handbook. McGraw-Hill Education.

5. Pietrikova, A., & Livovsky, L. (2020). Reliability of Electronic Packages and Semiconductor Devices. Springer.

6. Dorf, R. C. (Ed.). (2018). The Electrical Engineering Handbook. CRC Press.