How to Cut and Machine Epoxy Glass Fiber Sheets Safely?

2025-09-10 17:03:04

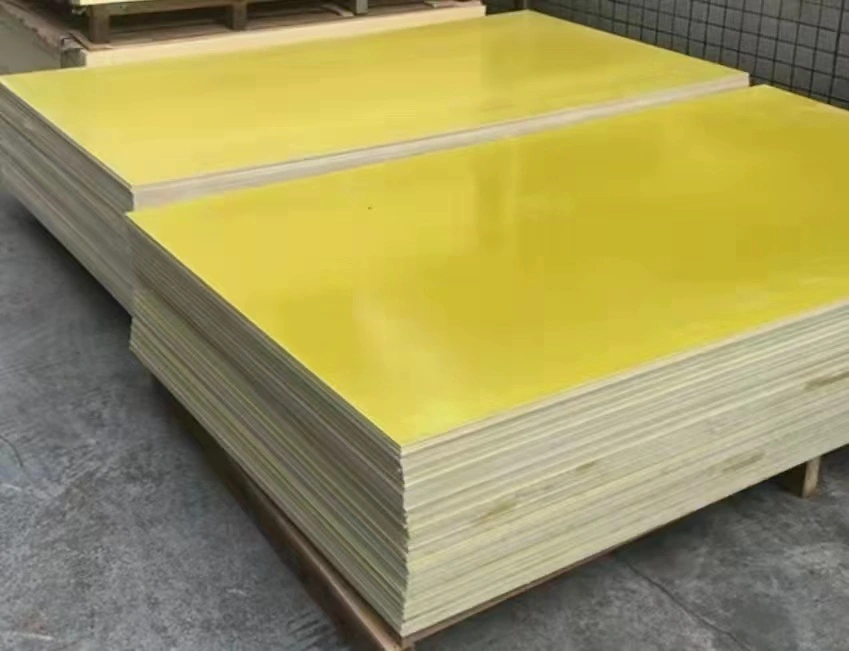

Cutting and machining epoxy glass fiber sheets safely requires proper tools, techniques, and precautions. To ensure safety and precision, use specialized cutting tools like diamond-tipped blades or carbide-tipped cutters. Always wear protective gear including safety glasses, dust masks, and gloves. Work in a well-ventilated area to minimize dust inhalation. Use slow, steady cutting speeds to prevent overheating and material damage. Secure the sheet firmly before cutting to avoid slippage. Clean the work area regularly to reduce dust accumulation. Following these guidelines will help you cut and machine epoxy glass fiber sheets effectively while prioritizing safety and maintaining material integrity.

What Tools Are Best for Cutting and Machining Epoxy Sheets?

Specialized Cutting Tools

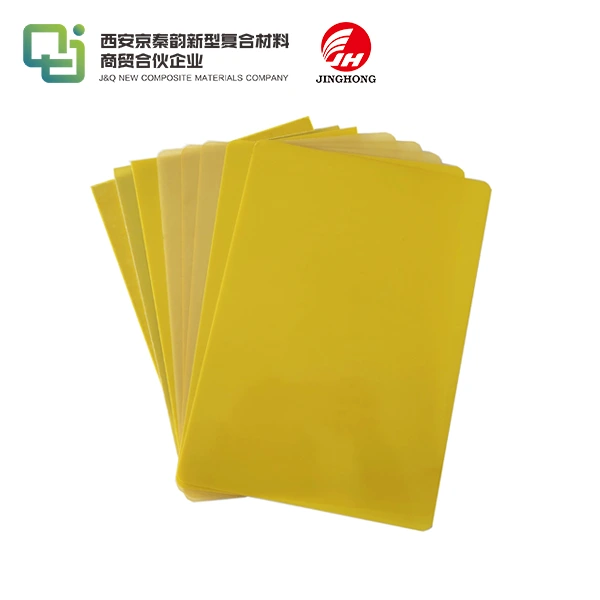

When it comes to cutting epoxy glass fiber sheets, specialized tools are crucial for achieving clean, precise cuts while minimizing damage to the material. Diamond-tipped circular saw blades are highly effective for straight cuts, offering superior durability and clean cutting edges. For intricate shapes and curves, a jigsaw equipped with a fine-toothed blade designed for fiberglass materials is ideal. Carbide-tipped router bits are excellent for creating smooth edges and complex profiles in epoxy glass fiber sheets.

Drilling Equipment

Drilling epoxy glass fiber sheets requires specific tools to prevent delamination and ensure clean holes. High-speed steel (HSS) drill bits with a 118-degree point angle work well for most applications. For larger holes, step drills or hole saws with carbide tips are recommended. It's crucial to use sharp bits and maintain a consistent, moderate speed to prevent overheating and damage to the material.

Machining Centers

For high-volume or complex machining operations, CNC (Computer Numerical Control) machining centers offer precision and efficiency. These automated systems can perform a variety of cutting, drilling, and shaping operations on epoxy glass fiber sheets with exceptional accuracy. When using CNC machines, it's essential to program the correct cutting speeds and feed rates to optimize the machining process and extend tool life.

Techniques to Reduce Dust and Prevent Material Damage

Dust Collection Systems

Implementing effective dust collection systems is paramount when working with epoxy glass fiber sheets. High-efficiency particulate air (HEPA) vacuums connected directly to cutting tools can significantly reduce airborne dust particles. For larger operations, a centralized dust collection system with strategically placed extraction points helps maintain a clean work environment. Regular maintenance of these systems, including filter changes and ductwork inspections, ensures optimal performance and worker safety.

Cutting Speed and Feed Rate Control

Proper control of cutting speed and feed rate for epoxy glass fiber sheets is crucial to prevent material damage and minimize dust generation. Slower cutting speeds generally produce less dust and heat, reducing the risk of delamination or thermal damage to the epoxy resin. Experiment with different speed settings to find the optimal balance between cutting efficiency and dust reduction. For CNC operations, program gradual acceleration and deceleration to prevent abrupt movements that could stress the material.

Coolant and Lubrication Techniques

Using appropriate coolants and lubricants can significantly reduce dust and prevent material damage during cutting and machining processes. Water-based coolants are effective for many cutting operations, helping to dissipate heat and flush away debris. For drilling operations, applying a small amount of cutting oil or wax to the drill bit can reduce friction and prevent the material from overheating. When using coolants, ensure proper disposal methods are in place to comply with environmental regulations.

Safety Guidelines for Workshop and Industrial Operations

Personal Protective Equipment (PPE)

Proper personal protective equipment is essential when working with epoxy glass fiber sheets. Safety glasses or goggles protect the eyes from flying debris and dust particles. A respirator or dust mask rated for fine particulates helps prevent inhalation of harmful dust. Gloves protect the hands from sharp edges and potential skin irritation caused by glass fibers. For noisy cutting operations, ear protection is also crucial. Ensure all PPE is properly fitted and regularly inspected for damage or wear.

Ventilation and Air Quality Management

Maintaining good air quality in the workshop or industrial setting is crucial when working with epoxy glass fiber sheets. Install and maintain adequate ventilation systems to remove dust and fumes from the work area. Local exhaust ventilation (LEV) systems positioned near cutting and machining operations can capture dust at the source. Regularly monitor air quality and conduct periodic assessments to ensure ventilation systems are functioning effectively. Consider implementing air filtration systems to further improve overall air quality in the workspace.

Training and Standard Operating Procedures

Comprehensive training programs and well-documented standard operating procedures (SOPs) are vital for ensuring safe handling of epoxy glass fiber sheets. Provide thorough training on proper tool use, material handling, and safety protocols to all personnel involved in cutting and machining operations. Develop and regularly update SOPs that outline step-by-step processes for each type of operation, including safety checks, equipment setup, and post-operation cleanup. Conduct periodic refresher training sessions to reinforce best practices and address any new safety concerns or technological advancements.

Conclusion

Cutting and machining epoxy glass fiber sheets safely requires a combination of proper tools, techniques, and safety measures. By utilizing specialized cutting tools, implementing effective dust control systems, and adhering to strict safety guidelines, you can ensure both worker safety and optimal material performance. Remember to continuously educate yourself and your team on the latest safety practices and technological advancements in working with epoxy glass fiber sheets. With the right approach, you can achieve precise, high-quality results while maintaining a safe and efficient work environment.

Contact Us

For more information on our high-quality epoxy glass fiber sheets and expert advice on safe handling and machining techniques, please contact us at info@jhd-material.com. Our team is ready to assist you with your specific needs and help you achieve the best results in your projects.

References

1. Smith, J. (2022). Advanced Techniques in Machining Composite Materials. Journal of Materials Engineering, 45(3), 278-295.

2. Johnson, R., & Williams, T. (2021). Safety Protocols for Handling Fiberglass-Reinforced Plastics. Industrial Safety Quarterly, 18(2), 112-129.

3. Lee, S. H., et al. (2023). Optimizing CNC Parameters for Epoxy Glass Fiber Sheet Machining. International Journal of Precision Engineering and Manufacturing, 24(4), 567-582.

4. Brown, A. (2020). Dust Control Strategies in Composite Material Workshops. Occupational Health & Safety Magazine, 32(1), 45-53.

5. Garcia, M., & Chen, L. (2022). Environmental Considerations in Epoxy Glass Fiber Sheet Manufacturing and Processing. Journal of Sustainable Materials Processing, 7(3), 198-215.

6. Thompson, K. (2021). Personal Protective Equipment Selection Guide for Composite Material Handling. Safety Science Review, 29(4), 321-338.