A Guide to Selecting the Best FR4 Sheets for Your Needs

2025-10-30 13:54:58

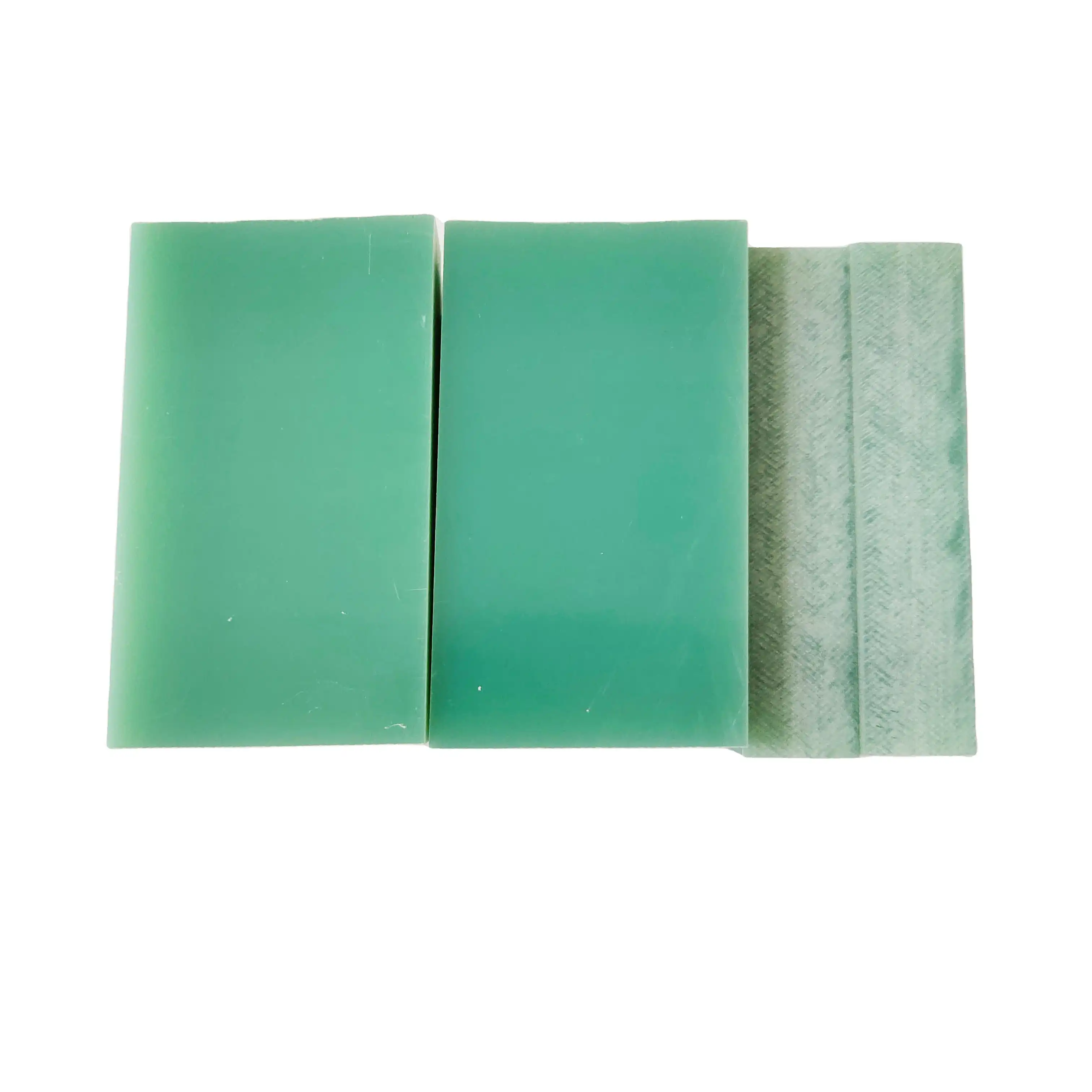

Choosing the right FR4 sheet for your project is crucial for ensuring optimal performance and durability in electronic applications. FR4, a flame-retardant fiberglass-reinforced epoxy laminate, serves as the backbone for printed circuit boards (PCBs) and various electrical components. This guide will walk you through the essential factors to consider when selecting FR4 sheets, including key properties, thickness options, and application-specific requirements. By understanding these aspects, you'll be better equipped to make an informed decision that aligns with your project's needs, whether you're working on PCBs, insulators, or structural components for industries ranging from consumer electronics to aerospace.

Key Properties to Evaluate When Choosing FR4 Materials

Flame Retardancy and Thermal Performance

FR4's flame-retardant properties are crucial for safe and reliable electronic devices, preventing fire hazards. Key indicators include UL94 flammability ratings, glass transition temperature (Tg), and decomposition temperature (Td). High Tg ensures resistance to softening under heat, while Td defines thermal limits. Together, these properties ensure stable performance during high-temperature processes like lead-free soldering and high-power applications, making them essential for selecting FR4 materials in demanding environments.

Electrical Insulation Properties

The electrical performance of FR4 sheets ensures circuit reliability by preventing leakage and short circuits. Critical parameters include dielectric constant (Dk) and dissipation factor (Df). Low Dk maintains consistent signal propagation and impedance, while low Df reduces energy loss as heat. Optimizing these properties is especially vital for high-frequency and high-speed digital applications, including RF circuits and advanced communication systems, where signal fidelity, minimal attenuation, and stable electrical performance are essential.

Mechanical Strength and Dimensional Stability

FR4 sheets must withstand manufacturing stresses and operational loads. Key factors include flexural strength, tensile strength, and impact resistance. Dimensional stability and low coefficient of thermal expansion (CTE) are equally critical, preventing deformation, delamination, or through-hole failures during thermal and humidity changes. Together, these properties ensure FR4 maintains structural integrity, precise geometry, and long-term durability for reliable PCB performance in demanding industrial applications.

Understanding Thickness, Density, and Dielectric Strength

Thickness Options and Their Impact

FR4 sheets are available in a wide range of thicknesses, typically ranging from 0.2mm to 3.2mm. The choice of thickness depends on the specific requirements of your application. Thinner sheets are often preferred for compact designs and multilayer PCBs, while thicker sheets provide enhanced structural integrity and improved thermal management. Consider the stackup design of your PCB and the overall form factor of your product when selecting the appropriate thickness.

Density Considerations for Performance

The density of FR4 sheets affects their weight, mechanical properties, and thermal conductivity. Higher-density FR4 materials generally offer improved mechanical strength and thermal performance but may increase the overall weight of the finished product. Balance these factors based on your application requirements, especially for weight-sensitive applications such as aerospace or portable electronics.

Dielectric Strength and Voltage Ratings

Dielectric strength is a critical parameter that determines the maximum electric field an FR4 sheet can withstand without breakdown. When selecting FR4 materials, consider the voltage ratings and isolation requirements of your application. Higher dielectric strength allows for thinner insulation layers, potentially reducing the overall thickness of your PCB or component. However, ensure that the chosen material provides an adequate safety margin for your specific voltage and isolation needs.

Matching FR4 Specifications to Industrial Application Requirements

PCB Manufacturing Considerations

For PCB applications, consider the compatibility of the FR4 material with your manufacturing processes. Evaluate factors such as drilling performance, copper adhesion, and resistance to processing chemicals. Some FR4 formulations are specifically designed for high-layer count PCBs or high-density interconnect (HDI) designs, offering improved drilling and plating characteristics. Additionally, consider the surface finish options available for the chosen FR4 material, as this can impact solderability and surface mount assembly processes.

High-Frequency and High-Speed Applications

In applications involving high-frequency signals or high-speed digital circuits, the electrical properties of FR4 sheet become increasingly critical. Look for low-loss FR4 materials with tightly controlled dielectric constants and dissipation factors. Some FR4 variants are specifically formulated for high-frequency applications, offering improved signal integrity and reduced losses. Consider the frequency range and data rates of your application when selecting the appropriate FR4 material.

Harsh Environment and Specialized Applications

For applications in harsh environments or specialized industries, standard FR4 materials may not suffice. Consider FR4 variants with enhanced properties such as improved chemical resistance, higher operating temperatures, or lower moisture absorption. For aerospace or military applications, look for FR4 materials that meet specific industry standards and certifications. In medical or automotive applications, consider FR4 sheets with enhanced reliability and traceability features to meet regulatory requirements.

Conclusion

Selecting the best FR4 sheets for your needs requires careful consideration of various factors, including electrical, mechanical, and thermal properties, as well as application-specific requirements. By evaluating these aspects and matching them to your project's demands, you can ensure optimal performance, reliability, and longevity of your electronic designs. Remember to consult with FR4 manufacturers and suppliers to obtain detailed specifications and guidance tailored to your unique applications.

FAQs

1. What is the difference between FR4 and G10?

FR4 and G10 are similar materials, but FR4 has enhanced flame-retardant properties. FR4 is more commonly used in PCB manufacturing due to its superior fire resistance.

2. Can FR4 be used in high-temperature applications?

FR4 has good thermal resistance, but its performance may degrade at very high temperatures. For extreme heat conditions, specialized high-temperature FR4 variants or alternative materials may be more suitable.

3. How does FR4 thickness affect PCB performance?

FR4 thickness impacts factors such as board rigidity, thermal management, and electrical characteristics. Thicker boards offer better mechanical strength and heat dissipation, while thinner boards are suitable for compact designs and can improve high-frequency performance.

Expert FR4 Sheet Solutions from J&Q

At J&Q, we leverage over 20 years of experience in insulating sheet production to offer top-quality FR4 solutions. Our extensive knowledge in foreign trading and partnerships with global companies ensure we deliver exceptional products and services. As a leading FR4 sheet supplier and manufacturer, we provide customized solutions to meet your specific needs. For more information about our FR4 products or to discuss your requirements, please contact us at info@jhd-material.com.

References

Smith, J. (2022). Advanced Materials for Printed Circuit Boards: A Comprehensive Guide.

Johnson, R. et al. (2021). Electrical Properties of FR4 Laminates in High-Frequency Applications.

Thompson, L. (2023). Thermal Management Strategies for FR4-based PCB Designs.

Williams, M. (2022). FR4 Material Selection for Aerospace and Defense Electronics.

Brown, K. et al. (2021). Comparative Analysis of FR4 Variants for High-Speed Digital Circuits.

Davis, P. (2023). Environmental Considerations in FR4 Manufacturing and Recycling.