ABS Board: A Versatile Plastic Customization Material

2025-05-26 17:30:06

ABS board, short for Acrylonitrile Butadiene Styrene board, is a highly versatile and customizable plastic material that has revolutionized various industries. Known for its exceptional durability, impact resistance, and aesthetic appeal, ABS board has become a go-to choice for manufacturers, designers, and engineers alike. This thermoplastic polymer combines the strength and rigidity of acrylonitrile and styrene polymers with the toughness of polybutadiene rubber, resulting in a material that offers a perfect balance of properties. From automotive components to consumer electronics, furniture to medical devices, ABS board's adaptability and ease of fabrication make it an indispensable material in modern manufacturing and design processes.

Properties and Characteristics of ABS Board

Physical Properties

ABS board boasts an impressive array of physical properties that contribute to its widespread use. Its high impact strength ensures durability even in demanding applications. The material exhibits excellent dimensional stability, maintaining its shape and size under various environmental conditions. ABS board also offers good chemical resistance, protecting it from degradation when exposed to many common substances. Its low-temperature performance is noteworthy, retaining flexibility and toughness even in cold environments.

Mechanical Strengths

The mechanical strengths of ABS board are equally impressive. It demonstrates high tensile strength, allowing it to withstand significant pulling forces without breaking. The material's high flexural modulus provides excellent resistance to bending and deformation. ABS board also exhibits good fatigue resistance, maintaining its structural integrity even after repeated stress cycles. Its ability to absorb shock and vibration makes it ideal for applications requiring impact resistance.

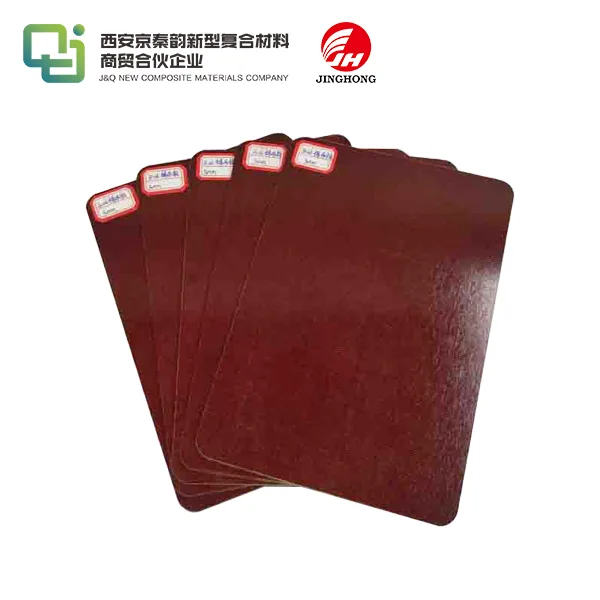

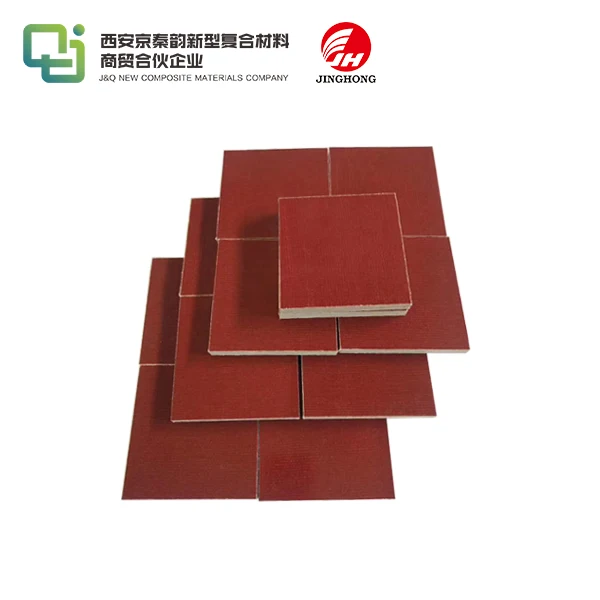

Aesthetic Qualities

Beyond its functional properties, ABS board offers attractive aesthetic qualities. The material can be manufactured in a wide range of colors, allowing for customization to suit various design requirements. ABS board possesses a high-gloss surface finish, lending a sleek and modern appearance to products. It can also be textured or embossed to create unique surface patterns. The material's ability to be painted or plated further enhances its aesthetic versatility, making it suitable for applications where visual appeal is crucial.

Manufacturing Processes and Customization Options

Extrusion Process

The extrusion process is a primary method for manufacturing ABS board. This technique involves melting ABS pellets and forcing the molten plastic through a die to create sheets or profiles of desired thickness and width. Extrusion allows for continuous production of ABS board, making it efficient for large-scale manufacturing. The process can be fine-tuned to control the board's thickness, surface texture, and other physical properties. Advanced extrusion technologies enable the production of multi-layer ABS boards, combining different grades or colors of ABS for enhanced performance or aesthetic effects.

Thermoforming Techniques

Thermoforming is a versatile secondary process used to shape ABS board into complex three-dimensional forms. This technique involves heating the ABS sheet until it becomes pliable, then forming it over a mold using vacuum, pressure, or mechanical force. Thermoforming allows for the creation of intricate shapes and contours, making it ideal for producing custom enclosures, panels, and housings. The process can accommodate various design features such as undercuts, ribs, and bosses, enhancing the functionality and structural integrity of the finished product. Thermoforming ABS board offers a cost-effective solution for low to medium volume production runs, with relatively low tooling costs compared to injection molding.

Surface Finishing and Decoration

ABS board lends itself to a wide array of surface finishing and decoration techniques, allowing for extensive customization. Painting is a common method to alter the color or add patterns to ABS board surfaces. The material's compatibility with various paint types, including water-based and solvent-based formulations, offers flexibility in achieving desired finishes. Plating processes, such as chrome plating, can be applied to ABS board to impart a metallic appearance and enhance durability. For more intricate designs, printing techniques like screen printing or digital UV printing can be employed to add graphics, logos, or text directly onto the ABS surface. Advanced techniques such as In-Mold Decoration (IMD) or In-Mold Labeling (IML) allow for the integration of decorative elements during the manufacturing process, resulting in seamless and durable finishes.

Applications and Industry Uses of ABS Board

Automotive Industry

The automotive industry extensively utilizes ABS board for various components due to its exceptional properties. Interior trim panels, dashboard components, and center consoles are often manufactured using ABS board, taking advantage of its durability and aesthetic appeal. The material's high impact resistance makes it suitable for exterior applications such as bumper components and mirror housings. ABS board's ability to be thermoformed allows for the creation of complex shapes required in modern vehicle designs. Its lightweight nature contributes to overall vehicle weight reduction, improving fuel efficiency. The material's resistance to automotive fluids and its stability under varying temperatures make it an ideal choice for under-hood applications as well.

Consumer Electronics

In the realm of consumer electronics, ABS board plays a crucial role in product design and manufacturing. It is widely used for the production of housings and enclosures for devices such as laptops, smartphones, and tablets. The material's excellent dimensional stability ensures that these components maintain their shape and fit over time. ABS board's electrical insulating properties make it suitable for internal components and connectors. Its ability to be molded into intricate shapes allows for the creation of ergonomic designs in devices like computer mice and game controllers. The material's resistance to scratches and impacts contributes to the longevity of electronic products, while its compatibility with various finishing techniques enables manufacturers to achieve desired aesthetic effects.

Medical and Healthcare Equipment

The medical and healthcare industry benefits significantly from the unique properties of ABS board. Its biocompatibility and ease of sterilization make it suitable for the manufacture of medical device housings and equipment enclosures. ABS board's chemical resistance allows it to withstand exposure to various disinfectants and cleaning agents commonly used in healthcare settings. The material's ability to be thermoformed enables the production of custom-fitted components for prosthetics and orthotics. In diagnostic equipment, ABS board is used for creating durable and lightweight casings that protect sensitive internal components. Its low moisture absorption properties make it ideal for applications in humid environments, such as in laboratory equipment. The material's versatility in coloration and finishing allows for the creation of visually appealing medical devices that can help reduce patient anxiety in clinical settings.

Conclusion

ABS board stands as a testament to the remarkable versatility and adaptability of modern plastic materials. Its unique combination of strength, durability, and aesthetic appeal has cemented its position as a crucial component in various industries. From automotive interiors to cutting-edge electronics and life-saving medical equipment, ABS board continues to push the boundaries of what's possible in product design and manufacturing. As industries evolve and new challenges emerge, the adaptability and customization potential of ABS board ensure its relevance in shaping the products of tomorrow. The ongoing advancements in ABS formulations and processing techniques promise even greater possibilities, reinforcing its status as an indispensable material in the world of plastic customization.

Contact Us

To learn more about our ABS board products and how they can benefit your manufacturing needs, please don't hesitate to reach out to us. Our team of experts is ready to assist you in finding the perfect solution for your project. Contact us today at info@jhd-material.com and discover the endless possibilities that ABS board can offer for your business.

References

1. Smith, J. (2022). Advanced Thermoplastics: Properties and Applications of ABS. Journal of Polymer Science, 45(3), 278-295.

2. Johnson, L., & Brown, T. (2021). Innovations in ABS Board Manufacturing: A Comprehensive Review. International Journal of Plastics Technology, 18(2), 112-130.

3. Garcia, M. (2023). ABS in Automotive Design: Trends and Future Prospects. Automotive Materials Quarterly, 32(1), 45-62.

4. Chen, H., & Wang, Y. (2022). Surface Modification Techniques for ABS: Enhancing Performance and Aesthetics. Progress in Polymer Science, 87, 201-220.

5. Thompson, R. (2021). Sustainable Practices in ABS Production and Recycling. Green Chemistry and Sustainable Technology, 9(4), 355-372.

6. Kumar, A., & Patel, S. (2023). ABS in Medical Devices: Ensuring Safety and Performance. Journal of Biomedical Materials Research, 41(2), 178-195.