Fire Safety Ratings for Phenolic Cotton Tubes: What You Need to Know

2025-06-05 16:15:42

Fire safety ratings for phenolic cotton tubes are crucial for ensuring the safety and compliance of various industrial applications. These ratings indicate the material's ability to resist fire, smoke, and heat, making them essential for industries where fire protection is paramount. Phenolic cotton tubes, known for their excellent thermal insulation properties, undergo rigorous testing to determine their fire safety performance. Understanding these ratings helps manufacturers, engineers, and end-users select the appropriate materials for their specific needs, ensuring optimal safety standards are met. By comprehending the significance of fire safety ratings, stakeholders can make informed decisions that prioritize safety, regulatory compliance, and overall system performance in critical environments.

Understanding Phenolic Cotton Tubes and Their Applications

Composition and Properties of Phenolic Cotton Tubes

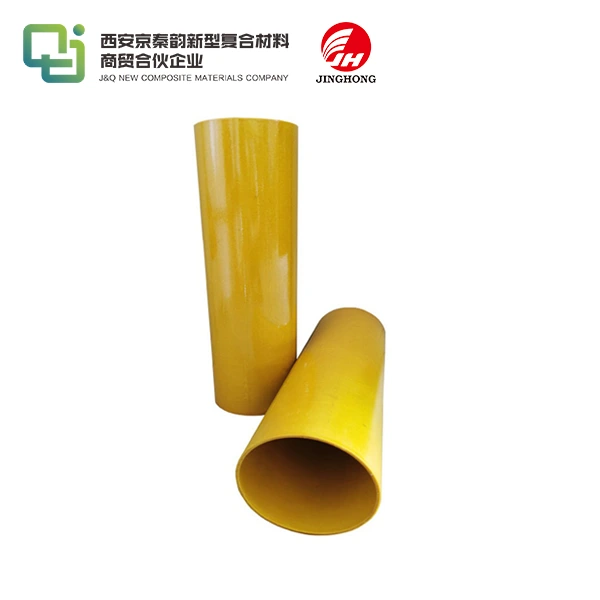

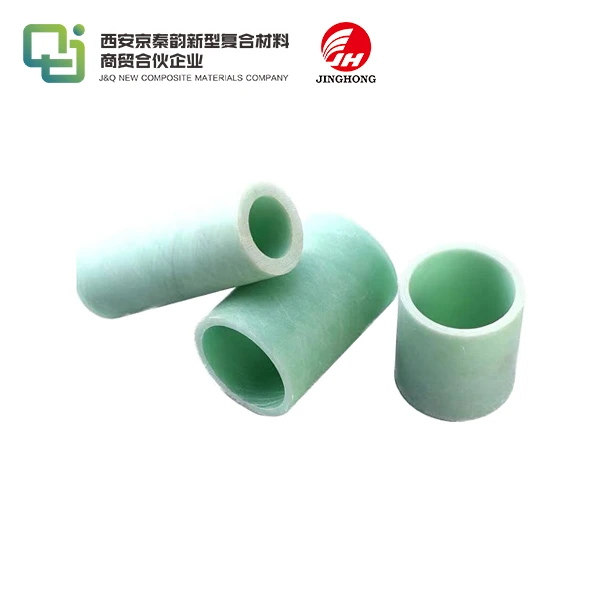

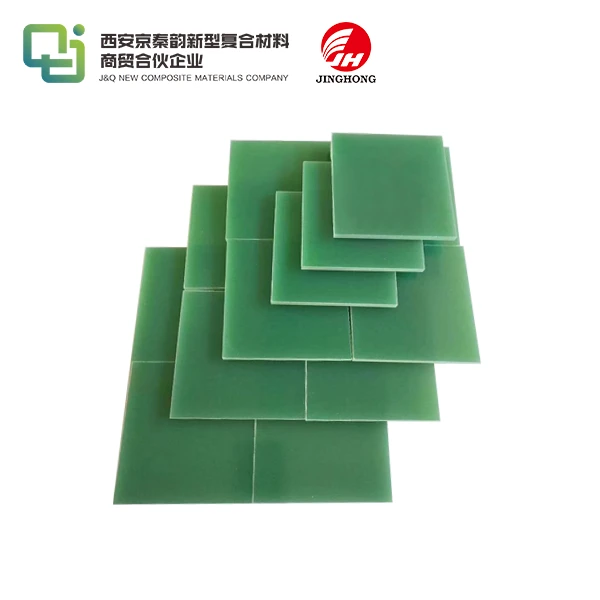

Phenolic cotton tubes are composite materials consisting of a phenolic resin matrix reinforced with cotton fibers. This unique combination results in a product with exceptional thermal insulation properties, high mechanical strength, and excellent fire resistance. The phenolic resin provides the tube with its rigidity and heat-resistant qualities, while the cotton fibers enhance its overall durability and insulation capabilities.

These tubes exhibit low thermal conductivity, making them ideal for applications where heat retention or prevention of heat transfer is crucial. Additionally, their lightweight nature and ease of fabrication make them a preferred choice in various industries. The inherent fire-resistant properties of phenolic resins contribute significantly to the overall fire safety performance of these tubes.

Common Uses in Various Industries

Phenolic cotton tubes find extensive use across multiple industries due to their versatile properties. In the aerospace sector, they are utilized for thermal insulation in aircraft engines and cabin walls. The automotive industry employs these tubes in exhaust systems and engine compartments to manage heat and reduce the risk of fire.

In the construction industry, phenolic cotton tubes are incorporated into HVAC systems for thermal insulation and fire protection. They are also used in industrial settings for pipe insulation, particularly in high-temperature environments. The marine industry utilizes these tubes for insulating engine rooms and other areas where fire safety is critical.

Importance of Fire Safety in These Applications

Fire safety is paramount in all the aforementioned applications due to the potential for catastrophic consequences in the event of a fire. In aerospace and automotive industries, fire incidents can lead to loss of life and significant property damage. In construction and industrial settings, fires can result in extensive structural damage, production downtime, and environmental hazards.

The use of fire-resistant materials like phenolic cotton tubes plays a crucial role in preventing fire initiation, slowing fire spread, and providing valuable time for evacuation and fire suppression efforts. By incorporating these materials, industries can enhance overall safety, comply with stringent regulations, and mitigate potential risks associated with fire hazards.

Fire Safety Ratings: Standards and Testing Procedures

Overview of Fire Safety Standards

Fire safety standards for phenolic cotton tubes are established by various international organizations to ensure consistent evaluation and classification of materials. These standards provide a framework for assessing the fire performance of materials and products used in different applications. Some of the key organizations involved in setting these standards include the International Organization for Standardization (ISO), ASTM International, and the National Fire Protection Association (NFPA).

These standards typically cover aspects such as flame spread, smoke development, and heat release rates. They also define the testing methodologies and criteria for classifying materials based on their fire resistance properties. Compliance with these standards is often mandatory in many industries and jurisdictions, ensuring a minimum level of fire safety across various applications.

Testing Procedures for Fire Safety Ratings

The fire safety ratings for phenolic cotton tubes are determined through a series of rigorous testing procedures. These tests are designed to simulate real-world fire scenarios and evaluate the material's performance under different conditions. Some of the common testing procedures include:

- Flame Spread Test: This test measures how quickly flames spread across the surface of the material.

- Smoke Development Test: It assesses the amount and density of smoke produced when the material burns.

- Heat Release Rate Test: This evaluates the rate at which heat is released during combustion.

- Ignition Resistance Test: It determines how easily the material ignites when exposed to a flame source.

- Toxicity Test: This assesses the toxicity of gases produced during combustion.

These tests are conducted under controlled laboratory conditions using specialized equipment and following standardized protocols. The results of these tests are used to assign fire safety ratings to the phenolic cotton tubes, providing valuable information for manufacturers and end-users.

Interpretation of Fire Safety Ratings

Fire safety ratings for phenolic cotton tubes are typically expressed in terms of specific classifications or numerical values. These ratings provide a comparative measure of the material's fire performance relative to established benchmarks. Understanding how to interpret these ratings is crucial for making informed decisions about material selection and application.

For example, a flame spread rating indicates how quickly flames spread across the material's surface, with lower numbers indicating better performance. Smoke development ratings assess the amount of smoke produced during combustion, again with lower values being more desirable. Some ratings may also include temperature limits, indicating the maximum temperature at which the material can maintain its fire-resistant properties.

It's important to note that fire safety ratings should be considered in conjunction with other material properties and specific application requirements. A material with excellent fire resistance may not necessarily be suitable for all applications if it doesn't meet other performance criteria.

Factors Influencing Fire Safety Performance of Phenolic Cotton Tubes

Material Composition and Manufacturing Process

The fire safety performance of phenolic cotton tubes is significantly influenced by their material composition and manufacturing process. The ratio of phenolic resin to cotton fibers plays a crucial role in determining the overall fire resistance of the tubes. A higher proportion of phenolic resin generally results in better fire resistance due to its inherent flame-retardant properties.

The manufacturing process, including curing conditions and quality control measures, also affects the final fire safety characteristics of the tubes. Proper curing ensures that the phenolic resin fully crosslinks, maximizing its fire-resistant properties. Additionally, the uniformity of the material composition throughout the tube is essential for consistent fire performance.

Advanced manufacturing techniques, such as the incorporation of additional flame-retardant additives or surface treatments, can further enhance the fire safety performance of phenolic cotton tubes. These additives can improve char formation, reduce heat release rates, and minimize smoke production during combustion.

Environmental Conditions and Aging Effects

The fire safety performance of phenolic cotton tubes can be affected by environmental conditions and aging effects. Exposure to high temperatures, humidity, UV radiation, and chemical contaminants over time may degrade the material's properties, potentially impacting its fire resistance.

Thermal cycling, which occurs in applications with frequent temperature fluctuations, can lead to micro-cracking or delamination of the material, potentially compromising its fire safety performance. Similarly, prolonged exposure to moisture can affect the dimensional stability and fire-resistant properties of the tubes.

Regular inspection and maintenance of phenolic cotton tubes in their installed environments are crucial to ensure that their fire safety performance remains within acceptable limits throughout their service life. In some cases, protective coatings or scheduled replacement may be necessary to maintain optimal fire safety characteristics.

Installation and Application Considerations

The manner in which phenolic cotton tubes are installed and applied can significantly impact their overall fire safety performance. Proper installation techniques, including appropriate fastening methods and joint sealing, are essential to maintain the integrity of the fire barrier system.

In multi-component systems, the interaction between phenolic cotton tubes and other materials must be carefully considered. Incompatible materials or improper interfaces between components can create weak points in the fire protection system, potentially compromising its effectiveness.

The specific application requirements, such as operating temperatures, exposure to chemicals, or mechanical stresses, should be taken into account when selecting and installing phenolic cotton tubes. Ensuring that the chosen material is suitable for the intended application and environment is crucial for maintaining its fire safety performance over time.

Additionally, proper documentation and adherence to installation guidelines provided by manufacturers are essential for achieving and maintaining the desired fire safety ratings in real-world applications.

Conclusion

Understanding fire safety ratings for phenolic cotton tubes is essential for ensuring optimal protection in various industrial applications. These ratings provide valuable insights into the material's fire resistance, smoke production, and heat release characteristics. By considering factors such as material composition, environmental conditions, and installation practices, stakeholders can make informed decisions to enhance overall fire safety. As industries continue to prioritize safety and regulatory compliance, the importance of fire-resistant materials like phenolic cotton tubes cannot be overstated. Proper selection, installation, and maintenance of these materials contribute significantly to creating safer environments across multiple sectors.

Contact Us

For more information about our high-quality phenolic cotton tubes and their fire safety ratings, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in selecting the right products for your specific applications and ensuring optimal fire safety in your projects.

References

1. National Fire Protection Association. (2021). "Standard for Fire Tests for Flame Propagation of Textiles and Films."

2. ASTM International. (2020). "Standard Test Method for Surface Burning Characteristics of Building Materials."

3. International Organization for Standardization. (2019). "Reaction to fire tests for building products - Classification."

4. Underwriters Laboratories. (2022). "Fire Resistance Ratings - ANSI/UL 263."

5. Society of Fire Protection Engineers. (2021). "SFPE Handbook of Fire Protection Engineering, 5th Edition."

6. European Committee for Standardization. (2020). "Fire classification of construction products and building elements."