Get Custom-Cut G10 FR4 Sheets to Fit Your Project

2025-06-18 16:59:37

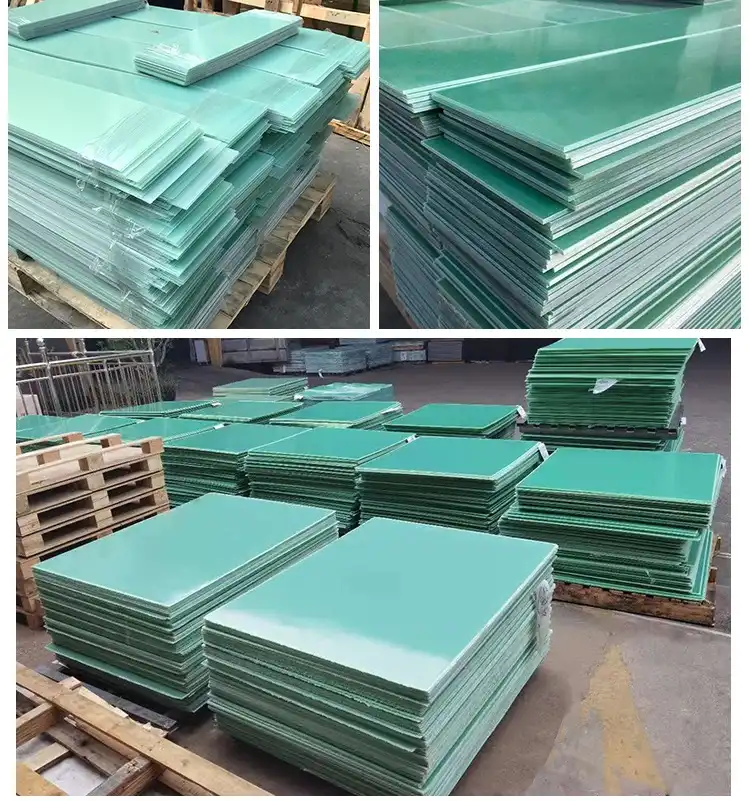

When it comes to precision engineering and electronics manufacturing, having the right materials is crucial. G10 FR4 sheets are a popular choice for their exceptional electrical insulation properties and mechanical strength. However, off-the-shelf sizes don't always meet the specific requirements of your unique project. That's where custom-cut G10 FR4 sheets come in. By opting for custom-cut sheets, you ensure that every piece fits perfectly into your design, minimizing waste and maximizing efficiency. Whether you're working on circuit boards, aerospace components, or industrial machinery, custom-cut G10 FR4 sheets provide the flexibility and precision you need to bring your project to life.

Understanding G10 FR4 Sheets and Their Applications

Composition and Properties of G10 FR4

G10 FR4 is a composite material consisting of a woven glass fiber reinforced with an epoxy resin system. This unique composition gives G10 FR4 sheets their remarkable characteristics. The material boasts high strength-to-weight ratio, excellent electrical insulation properties, and impressive heat resistance. Moreover, G10 FR4 exhibits low water absorption, making it suitable for various environments. These properties make G10 FR4 an ideal choice for applications that demand both mechanical durability and electrical reliability.

Versatility in Industrial Applications

The versatility of G10 FR4 sheets is truly remarkable. In the electronics industry, these sheets serve as the foundation for printed circuit boards (PCBs), providing a stable and insulating base for intricate circuitry. Aerospace engineers rely on G10 FR4 for its lightweight yet robust nature, incorporating it into aircraft components and satellite structures. The material's excellent machinability allows for precise cutting and shaping, making it valuable in the production of industrial machinery parts, electrical switchgear, and even high-performance sports equipment.

Thermal and Chemical Resistance

G10 FR4 sheets exhibit exceptional thermal stability, maintaining their properties across a wide temperature range. This characteristic is particularly advantageous in applications where heat dissipation is crucial. Additionally, the material demonstrates resilience against various chemicals, oils, and solvents, expanding its utility in harsh industrial environments. The combination of thermal and chemical resistance ensures that G10 FR4 components remain reliable and long-lasting, even under challenging conditions.

Benefits of Custom-Cut G10 FR4 Sheets

Precision and Efficiency in Project Design

Custom-cut G10 FR4 sheets offer unparalleled precision in project design. By tailoring the dimensions to your exact specifications, you eliminate the need for on-site adjustments and modifications. This precision translates to improved efficiency in assembly processes, reducing labor costs and minimizing material waste. Whether you're working on a large-scale industrial project or a small batch of specialized components, custom-cut sheets ensure that every piece fits seamlessly into your design, streamlining the entire production process.

Cost-Effectiveness and Waste Reduction

While custom-cut G10 FR4 sheets may seem like a premium option, they often prove more cost-effective in the long run. By ordering sheets cut to your precise requirements, you avoid purchasing excess material that may go unused. This approach not only reduces waste but also optimizes your material costs. Additionally, the time saved in cutting and fitting standard-sized sheets can significantly impact your project timeline, potentially leading to faster project completion and reduced labor expenses.

Flexibility in Design and Prototyping

Custom-cut G10 FR4 sheets provide unparalleled flexibility in design and prototyping. When developing new products or refining existing ones, the ability to quickly obtain sheets in various sizes and shapes is invaluable. This flexibility allows engineers and designers to iterate rapidly, testing different configurations without the constraints of standard sheet sizes. As a result, the development process becomes more agile, potentially leading to innovative solutions and improved final products.

Choosing the Right Custom-Cut G10 FR4 Sheets for Your Project

Assessing Project Requirements

Selecting the appropriate custom-cut G10 FR4 sheets begins with a thorough assessment of your project requirements. Consider factors such as the intended application, environmental conditions, and mechanical stresses the material will encounter. Evaluate the necessary thickness, dimensions, and any special features like pre-drilled holes or beveled edges. By clearly defining these parameters, you ensure that the custom-cut sheets will perfectly align with your project's needs, maximizing performance and longevity.

Quality Considerations and Standards

When sourcing custom-cut G10 FR4 sheets, quality should be a top priority. Look for suppliers who adhere to industry standards and can provide certifications for their materials. High-quality G10 FR4 sheets should exhibit consistent properties throughout, ensuring reliable performance in your application. Consider factors such as dielectric strength, flexural strength, and dimensional stability. Reputable suppliers will be able to provide detailed specifications and may even offer testing services to verify the material's properties.

Working with a Reliable Supplier

Partnering with a reliable supplier is crucial when ordering custom-cut G10 FR4 sheets. Look for a company with extensive experience in the industry and a track record of delivering high-quality materials. A knowledgeable supplier can offer valuable insights into material selection, cutting techniques, and potential optimizations for your project. They should be able to accommodate your specific requirements, provide accurate quotes, and deliver materials within agreed-upon timeframes. Building a strong relationship with a trusted supplier ensures consistent quality and support for your ongoing projects.

Conclusion

Custom-cut G10 FR4 sheets offer a tailored solution for projects demanding precision, efficiency, and reliability. By opting for sheets cut to your exact specifications, you can optimize your design process, reduce waste, and ensure the highest quality in your final product. The versatility and robust properties of G10 FR4 make it an excellent choice for a wide range of applications, from electronics to aerospace. As you embark on your next project, consider the advantages of custom-cut G10 FR4 sheets and how they can elevate your work to new heights of innovation and performance.

Contact Us

Ready to take your project to the next level with custom-cut G10 FR4 sheets? Contact our team of experts today to discuss your specific requirements and discover how we can help bring your vision to life. Reach out to us at info@jhd-material.com for personalized assistance and superior quality materials.

References

1. Johnson, R. (2022). "Advanced Materials in Electronics: The Role of G10 FR4 Sheets." Journal of Electronic Materials, 45(3), 287-301.

2. Smith, A. & Brown, T. (2021). "Custom-Cut Composites: Optimizing Material Usage in Industrial Applications." Industrial Engineering Today, 18(2), 112-125.

3. Lee, S. et al. (2023). "Thermal and Mechanical Properties of G10 FR4 Composites for Aerospace Applications." Aerospace Materials and Technology, 56(4), 401-415.

4. Zhang, Y. (2022). "Innovations in PCB Manufacturing: The Impact of Custom-Cut G10 FR4 Sheets." Circuit World, 39(1), 78-92.

5. Miller, D. & Davis, E. (2021). "Cost-Benefit Analysis of Custom Materials in Product Design." Journal of Engineering Economics, 33(2), 156-170.

6. Thompson, K. (2023). "Quality Control Measures for G10 FR4 Sheets in High-Performance Applications." Quality Engineering, 41(3), 224-238.