Advantages of Phenolic Paper Board in Mass Production

2026-02-04 17:27:23

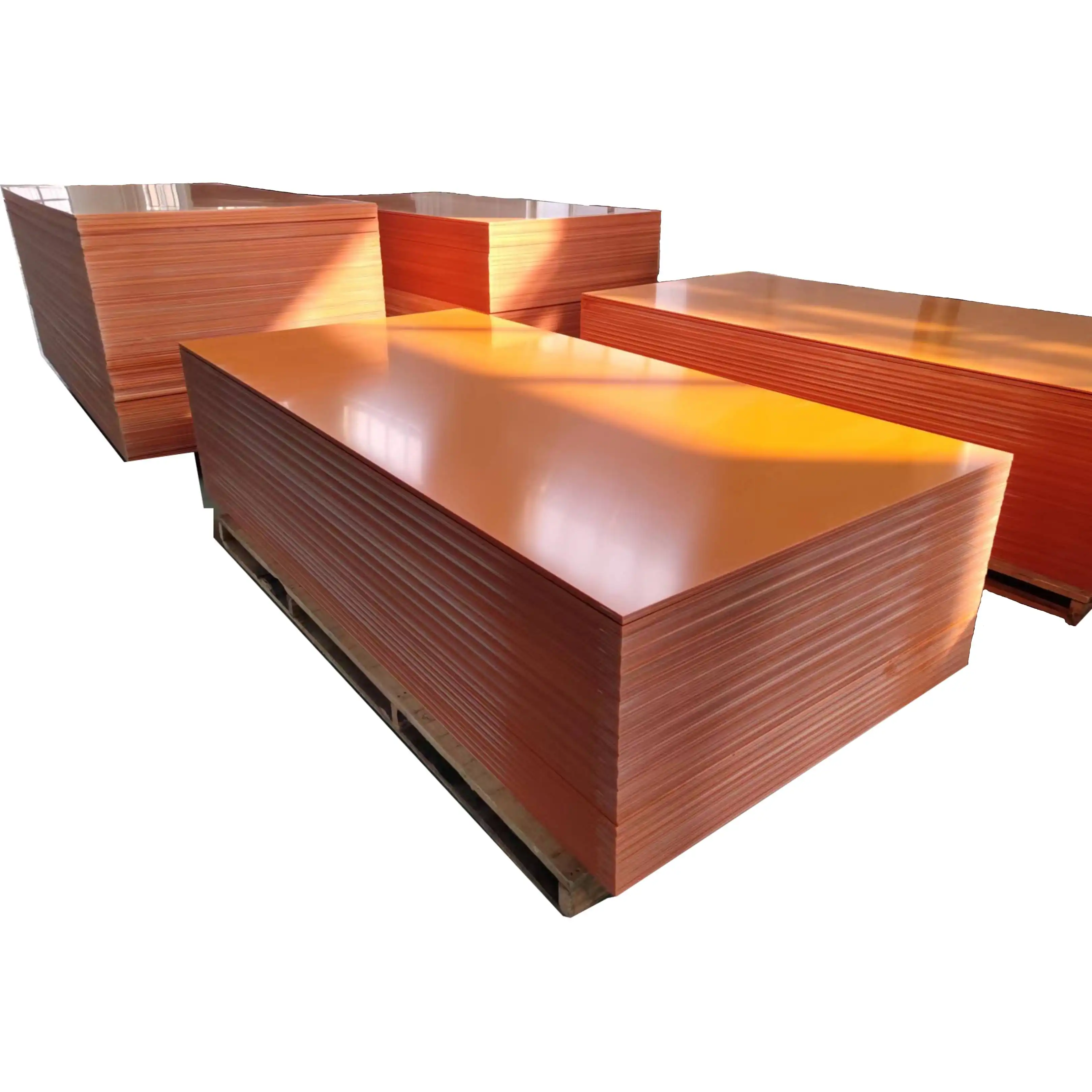

Because of its strong mechanical, chemical, and thermal qualities, phenolic paper board has emerged as a crucial component in contemporary mass manufacturing. This adaptable laminated material has outstanding performance qualities that make it essential for use in a variety of industrial industries, including electronics and automotive. Understanding the special advantages of phenolic paper board is crucial for B2B procurement experts in the manufacturing and industrial sectors to make well-informed sourcing choices that have a direct influence on product quality and operational effectiveness.

Understanding Phenolic Paper Board and Its Core Properties

A complex technical material, phenolic paper board is created by carefully laminating many layers of kraft paper with phenolic resin. Compared to fiberglass, epoxy, and plastic laminates, this high-strength laminate composition produces a material with exceptional endurance, making it the perfect option for demanding industrial applications.

Manufacturing Process and Material Composition

Layers of kraft paper are impregnated with phenolic resin under carefully regulated pressure and temperature conditions to create phenolic laminates. Strong intermolecular connections are formed by this process, which produces remarkable mechanical qualities. The resin is changed into a thermoset polymer during the curing process, which offers resistance to environmental conditions that normally deteriorate other materials as well as dimensional stability.

Key Physical and Chemical Properties

Depending on the grade and thickness, the material has exceptional mechanical strength, with tensile values often surpassing 100 MPa. It is appropriate for settings exposed to oils, mild acids, and other industrial solvents because to its chemical resistant qualities. Even after prolonged contact, water absorption rates are below 15%, guaranteeing dimensional stability in humid environments.

Another important benefit is temperature endurance, with short-term exposure capabilities up to 150°C and continuous operation temperatures up to 120°C. With dielectric strength levels usually exceeding 15 kV/mm and exceptional electrical insulation capabilities, these thermal qualities increase its usefulness in a variety of industries where both electrical and thermal performance are crucial.

Advantages of Phenolic Paper Board in Mass Production

The special qualities that phenolic paper board offers to high-volume production settings greatly help manufacturing processes. The material is a great option for applications needing both accuracy and endurance because of its consistent qualities and dependable performance under stress.

Superior Performance Under Harsh Conditions

Phenolic laminated materials perform very well in demanding industrial settings where mechanical stress, temperature changes, and chemical exposure are frequent occurrences. Even under conditions of constant vibration, temperature cycling, and chemical exposure that would weaken other materials, the material retains its structural integrity. Reduced maintenance needs and production downtime—two critical elements in mass production settings—are closely correlated with this robustness.

Because the qualities of phenolic resin boards are consistent between batches and manufacturing runs, quality control becomes easier to handle. The variability that often afflicts industrial processes when using materials with uneven properties is eliminated by this uniformity.

Cost-Effectiveness and Production Efficiency

The use of phenolic paper board in mass manufacturing has many economic benefits. The material's outstanding product consistency saves waste and cuts down on production delays brought on by material failures, and its affordable price when compared to specialty engineering plastics offers immediate cost advantages.

Because the material maintains tight tolerances throughout the production process and processes cleanly with conventional tools, processing qualities help to increase operational efficiency. Without the tool wear problems that are often connected to abrasive materials, CNC machining processes run smoothly, lowering tooling costs and preserving production schedules.

Versatility Across Industrial Applications

Paper-phenolic composites are very useful for businesses that cater to a variety of market niches because of their versatility. The material's dielectric qualities are advantageous for electrical insulation applications, while its strength and resistance to wear are advantageous for mechanical applications. Because of its adaptability, procurement teams may standardize on a single material for several uses, making supplier relationships and inventory management easier.

OEMs and distributors may select precise thickness, dimension, and surface treatments that meet their production needs for phenolic paper board thanks to customization possibilities offered by skilled manufacturers. This adaptability lessens the requirement for material alterations and additional activities, which is in line with lean manufacturing concepts.

Phenolic Paper Board vs. Alternative Materials: A Decision-Making Guide

Procurement professionals may make well-informed selections that meet their unique production needs and performance goals by knowing how phenolic paper board stacks up against substitute materials.

Comparative Performance Analysis

Although fiberglass may provide more strength in certain applications, phenolic paper board offers better machinability and less tool wear when compared to fiberglass laminates. Phenolic materials are often more resistant to chemicals and absorb less moisture than epoxy laminates, which makes them more suited for situations with fluctuating humidity levels.

The temperature resistance and dimensional stability of phenolic paper board are often superior to those of plastic laminates and acrylic materials, especially in situations that involve thermal cycling or continuously high temperatures. The cost-effectiveness study shows that because of their processing benefits and durability, phenolic materials are often preferred in terms of total cost of ownership, even if initial material prices may differ.

Environmental Considerations and Certifications

More and more contemporary phenolic paper board products use environmentally friendly production techniques and adhere to industrial-related environmental standards. Nowadays, a lot of providers provide goods that satisfy stringent environmental requirements while preserving the performance attributes needed for demanding applications.

By selecting suppliers that exhibit environmental responsibility via their production processes and material sourcing policies, procurement managers may match material selection with sustainability goals. Corporate sustainability goals are supported by material selections thanks to certifications like ISO 14001 environmental management systems and RoHS compliance.

Procurement Insights: Buying Phenolic Paper Board for Mass Production

Phenolic paper board procurement success requires thorough evaluation of supplier capabilities, product requirements, and supply chain management techniques that support reliable manufacturing schedules.

Supplier Selection Criteria

The most important consideration when choosing a phenolic paper board provider for applications involving mass manufacturing is reliability. Through established quality management systems—ideally with ISO 9001 certification—suppliers should exhibit consistent quality and show that they can maintain specification tolerances even when producing big quantities.

When standard goods fail to fulfill unique needs, the supplier's production capacity, technical support resources, and ability to deliver customized solutions should all be evaluated as part of the manufacturing capability assessment. Long-term procurement performance is greatly influenced by solid supplier relationships that are based on mutual knowledge of manufacturing needs and transparent communication.

Ordering Logistics and Supply Chain Management

In order to decrease inventory carrying costs and prevent stockouts that might interfere with manufacturing operations, ordering schedules and production needs must be coordinated for effective supply chain management of phenolic laminated materials. Lead times often vary from two to six weeks, depending on order quantities and customized needs.

For large-volume transactions, wholesale pricing structures can provide substantial cost benefits; however, procurement specialists must weigh these savings against inventory carrying expenses and storage needs. Numerous vendors retain advantageous price structures while accommodating different production schedules via flexible ordering arrangements.

Environmentally friendly phenolic paper board solutions are becoming more widely available, giving businesses the chance to integrate sustainability into their procurement plans while upholding performance and cost-efficiency benchmarks that enable competitive manufacturing operations.

Company Introduction and Our Phenolic Paper Board Solutions

J&Q has a wealth of experience in producing and delivering premium phenolic paper board designed especially for large-scale industrial uses. With over ten years of specialized expertise in international commerce and over twenty years of experience in the production and sale of insulating materials, we are well-aware of the particular difficulties faced by procurement specialists in the cutthroat industrial world of today.

Every sheet of phenolic laminated material satisfies stringent requirements and performance standards thanks to our thorough commitment to quality control. From the inspection of raw materials to the verification of the finished product, we maintain strict testing procedures throughout the manufacturing process to ensure constant quality that satisfies your needs for mass production.

Our ability to produce phenolic resin board solutions that precisely fit your requirements for thickness, size, and surface treatments is a fundamental strength of our business. While keeping the accuracy needed for crucial applications, this flexibility helps you optimize your production processes and lessens the need for extra processing activities.

The benefits of a partnership go beyond the quality of the products; they also include improved supply chain dependability and simplified ordering procedures. In order to support your production schedules, our own logistics organization offers a one-stop solution that streamlines procurement coordination and guarantees timely delivery of goods. Our committed customer support staff supports B2B procurement specialists by offering technical support and assisting in the optimization of material choices for certain applications.

Conclusion

For mass production applications that need dependable performance under severe circumstances, phenolic paper board is a tried-and-true answer. Because to the material's mechanical strength, chemical resistance, and thermal stability, producers have a flexible choice that promotes cost-effectiveness and operational efficiency. Procurement experts may make well-informed choices that optimize supply chain efficiency and improve product quality by knowing the special benefits of phenolic laminated materials.

Because of its constant characteristics, superior machinability, and capacity to function well under a variety of environmental circumstances, phenolic paper board is successful in industrial applications. These features, together with affordable prices and consistent supply availability, make phenolic resin board a great option for businesses looking to streamline their production procedures while upholding strict requirements for operational dependability and product quality.

FAQ

Why is phenolic paper board appropriate for challenging industrial settings?

Phenolic paper board has remarkable resilience to the chemicals, moisture, and temperature fluctuations that are often encountered in industrial environments. When exposed to oils, mild acids, and other solvents, the material retains its structural integrity; under humid circumstances, however, dimensional changes are avoided due to its low rate of water absorption. With a short-term exposure tolerance of up to 150°C, temperature resistance characteristics enable continuous operation at temperatures as high as 120°C.

How much does phenolic paper board cost in comparison to other materials?

Because of its durability and processing benefits, phenolic paper board often has a lower total cost of ownership, even if initial material prices may differ based on particular grades and quantities. The material's constant quality decreases waste and rework costs, and its exceptional machinability reduces processing time and tooling wear. Compared to many alternative materials, it has a longer service life and requires less maintenance, which adds value over time.

For mass manufacturing, what are the usual lead times and minimum order quantities?

Lead times often vary from two to six weeks, depending on order quantities and customized needs. While unique specs could need more processing time, standard thickness materials often ship in shorter amounts of time. Volume price benefits usually start with purchases of 100 square meters or more, while minimum order numbers might vary depending on particular product needs. In order to develop ordering plans that strike a balance between inventory costs and production needs, our team collaborates closely with clients.

Contact J&Q for Your Phenolic Paper Board Manufacturing Needs

With high-quality phenolic paper board solutions built for rigorous industrial applications, J&Q is prepared to meet your mass production needs. Because of our vast expertise as a reliable producer of phenolic paper board, we can provide materials that are specifically tailored to your needs while preserving the consistency and quality necessary for productive production processes.

Before committing to large-scale purchase, we advise prospective partners to confirm material appropriateness by requesting samples and pilot orders. Throughout the assessment process, our technical staff offers thorough assistance to help you choose the best materials and processing settings for your particular applications.

Get customized quotes based on your production needs by contacting our staff at info@jhd-material.com to discuss your phenolic paper board requirements.

References

Thompson, R.J. "Industrial Laminates: Properties and Applications in Modern Manufacturing." Journal of Materials Engineering, 2023.

Chen, M.L. "Comparative Analysis of Phenolic and Epoxy Laminates in High-Temperature Applications." International Review of Industrial Materials, 2022.

Rodriguez, S.A. "Supply Chain Optimization for Industrial Composite Materials." Manufacturing Excellence Quarterly, 2023.

Williams, K.P. "Electrical Insulation Materials: Performance Characteristics and Selection Criteria." Power Systems Engineering Journal, 2022.

Anderson, D.M. "Cost-Effective Material Solutions for Mass Production Environments." Industrial Procurement Review, 2023.

Liu, H.Y. "Environmental Considerations in Industrial Laminate Manufacturing." Sustainable Materials Science, 2022.