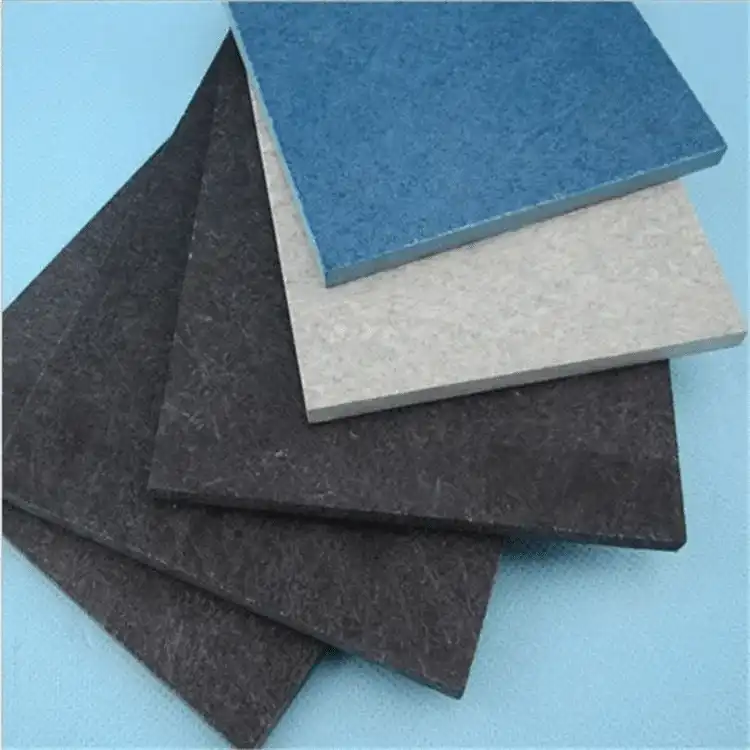

High Temperature Resistant Synthetic Stone: Black Slate Concept

2026-02-04 17:27:26

High Temperature Resistant Synthetic Stone marks a new development in made materials, joining advanced polymer chemistry with natural mixtures to make surfaces that survive high heat conditions. The Black Slate idea specifically addresses the rising demand for synthetic stone solutions that offer both physical appeal and exceptional heat stability. Through sophisticated manufacturing processes involving high-pressure compression and controlled curing, these engineered materials deliver superior performance compared to traditional natural stones while maintaining the visual characteristics that make slate so desirable in industrial and commercial applications.

Understanding High Temperature Resistant Synthetic Stone

Modern manufactured stone materials have changed the world of industrial uses, especially where heat resistance becomes important. These advanced composites combine carefully chosen mineral fillers with high-performance resins, creating materials that excel in conditions where standard options fail.

Core Composition and Manufacturing Technologies

The base of high temperature resistant synthetic stone lies in its complex material structure. Premium quartz particles, usually containing 90-95% of the makeup, provide structural strength and heat stability. The remaining 5-10% consists of polymer adhesives especially designed for high-temperature uses. During production, these components experience vacuum compression at temperatures topping 180°C, forming a thick, non-porous structure that resists heat expansion and contraction.

Advanced resin systems used in these applications include modified acrylic polymers and specialized epoxy compounds that keep their structure qualities at temperatures reaching 300°C. The manufacturing method includes multiple quality control steps, ensuring uniform temperature performance across production runs. Each slab receives thermal cycle tests to prove its resistance to temperature changes widely found in industrial settings.

Thermal Stability Advantages Over Traditional Materials

When comparing temperature efficiency, engineered stone products like synthetic stone regularly beat natural options. The managed makeup removes the weak places found in natural stone, where mineral differences can cause heat stress concentrations. Laboratory testing shows that high-quality manufactured options keep physical stability at temperature ranges where real granite or marble would develop micro-cracks.

The regular spread of heat stress across the designed structure avoids the isolated breakdowns common in natural materials. This uniformity becomes particularly useful in applications involving repeated heating cycles, where material wear can compromise performance over time. Industrial sites utilizing these materials report greatly lowered upkeep needs compared to setups using standard stone goods.

Comparing Black Slate Synthetic Stone with Traditional Materials

Understanding the performance differences between manufactured and natural materials helps buying workers make informed choices. These similarities extend beyond simple cost factors to include term value and operating efficiency.

Performance Metrics Against Natural Stone Options

Natural slate usually handles temperatures up to 200°C before suffering structure changes, while manufactured replacements keep their qualities at temperatures topping 300°C. The porosity differences are equally important - natural materials often show porosity values of 0.5-2%, compared to less than 0.1% for quality manufactured goods. This reduced porosity leads directly to better heat shock protection and chemical compatibility.

Thermal expansion factors provide another important comparing point. Natural slate grows at rates of 8-12 x 10⁻⁶ per degree Celsius, while manufactured options usually show expansion rates of 6-8 x 10⁻⁶ per degree Celsius. This reduced expansion greatly lessens installation stress and reduces the risk of cracking in uses involving temperature changes.

Cost-Effectiveness and Lifecycle Analysis

While beginning material prices may vary, the total maintenance cost often favors designed solutions. Maintenance needs drop greatly due to better stain protection and heat stability. Natural materials often require finishing processes every 1-2 years, while manufactured options usually keep their performance traits for 5-10 years without interference.

The uniformity of designed goods, like synthetic stone, also lowers waste during installation and manufacturing. Natural stone waste rates regularly reach 15-20% due to natural differences and flaws, while manufactured materials typically achieve waste rates below 5%. This efficiency leads to lower project costs and more stable material needs for large-scale installations.

Application Areas and Performance of Black Slate Synthetic Stone

The flexibility of high temperature resistant designed materials opens possibilities across various industry and business sectors. Understanding these application areas helps buyers find ideal options for their individual needs.

Industrial and OEM Applications

Manufacturing sites increasingly require these materials for equipment housings and heat shields. Electronics makers utilize them for component mounting areas where physical stability under temperature cycle becomes important. The car industry uses these materials in battery pack housings and engine room applications where standard materials cannot keep their qualities.

Power production centers form another major application area. Transformer housings and electrical panel components benefit from the better insulating qualities and temperature stability. These systems often work in settings where temperatures regularly reach 250°C, making standard materials unsuitable for long-term trustworthiness.

Commercial and Architectural Uses

High-traffic business settings demand materials that keep their look under difficult conditions. Restaurant cooking surfaces and food service equipment housings require materials that survive both temperature shock and chemical contact. The non-porous nature of designed replacements stops germ growth while keeping easy cleaning routines.

Outdoor building uses gain from UV stability and corrosion resistance. Unlike natural materials that may fade or develop surface degradation over time, manufactured goods keep their original look for decades. This life becomes particularly useful in situations where repair costs include major structure changes.

Performance Documentation and Case Studies

Independent testing centers have recorded the long-term success of synthetic stone materials in difficult settings. A major electronics maker reported zero thermal-related problems across 50,000 units utilizing designed stone mounting surfaces over a three-year period. Similar setups using standard materials experienced failure rates of 2-3% under similar conditions.

Commercial kitchen setups show the real benefits of better heat protection. Facilities utilizing manufactured surfaces report upkeep cost reductions of 60-70% compared to natural stone alternatives. The removal of frequent closing needs and lower replacement frequency adds greatly to these saves.

Procuring High Temperature Resistant Synthetic Stone: A Buyer's Guide

Successful buying requires knowing both technical requirements and provider skills. This understanding ensures ideal material selection while reducing project risks.

Supplier Evaluation and Quality Standards

Reputable providers keep extensive quality paperwork including temperature performance tests, physical stability proof, and chemical protection data. Industry approvals such as GREENGUARD and NSF provide third-party proof of performance claims. Suppliers should easily provide test reports showing agreement with important business standards.

Manufacturing stability becomes important for big projects needing multiple orders. Quality providers apply statistical process controls ensuring batch-to-batch uniformity within defined limits. This uniformity avoids color changes and performance differences that can compromise installation quality.

Pricing Models and Bulk Order Advantages

Volume price usually becomes available for sales reaching 1,000 square feet, with extra savings for bigger amounts. Many sellers offer project-specific pricing that considers total volume across multiple orders, allowing buyers to secure volume pricing while keeping flexible delivery schedules.

Customization capabilities for synthetic stone vary significantly among suppliers. Premium makers offer color matching services and unique width choices, while others focus on standard product lines. Understanding these skills during the selection process avoids delays and extra costs later in the project timeline.

J&Q: Your Trusted Partner for High Temperature Resistant Synthetic Stone Solutions

J&Q brings over two decades of experience in making and providing specialized insulation materials, with more than ten years devoted to foreign markets. Our experience in creating high-temperature resistant materials stretches across multiple industries, serving clients who expect excellent thermal performance and dependability.

Manufacturing Excellence and Product Innovation

Our production sites feature modern manufacturing technologies that ensure uniform quality across all product lines. The Black Slate line reflects our latest innovation in high-temperature resistant engineering materials, merging visual appeal with better thermal stability. Each product receives thorough testing methods that prove performance traits before shipment.

Quality control methods include temperature cycle tests, physical stability verification, and chemical resistance assessment. These thorough testing methods guarantee that every package meets or exceeds stated performance standards. Our manufacturing methods meet with international quality standards, giving customers with trust in long-term product performance.

Global Supply Chain and Customer Service

Our combined shipping skills, including our own delivery network, allow us to provide full supply chain solutions. This combination helps us to keep affordable prices while ensuring reliable delivery plans. Long-standing ties with foreign trade partners provide extra freedom for complicated project needs.

Technical support services include material design help, application advice, and performance improvement suggestions. Our tech team works directly with customers to find best solutions for particular application needs. This joint method ensures that material choices match with both scientific needs and price limits.

Conclusion

High Temperature Resistant Synthetic Stone materials, especially the Black Slate idea, represent a major development in manufactured surface options. These materials offer better temperature efficiency, stability, and lifetime value compared to standard options. The mix of advanced manufacturing methods and carefully designed material compositions creates products that shine in challenging industrial and business uses. For procurement professionals seeking reliable solutions for high-temperature settings, designed options provide the performance characteristics necessary for long-term success while giving the stylistic qualities that make projects visually attractive.

FAQ

How does Black Slate synthetic stone work compared to real slate at high temperatures?

Engineered Black Slate materials keep structure integrity at temperatures reaching 300°C, while natural slate usually starts suffering degradation around 200°C. The managed makeup removes weak places found in natural materials, giving better thermal shock protection and physical stability.

What upkeep needs are linked with high temperature resistant designed materials?

These materials require minimal upkeep due to their non-porous structure and chemical protection. Unlike real stone that needs occasional coating, manufactured replacements usually keep their performance traits for 5-10 years without interference. Regular cleaning with standard industrial cleaners is suitable for most uses.

Can Black Slate synthetic stone be adapted for specific industrial applications?

Yes, reliable makers offer extensive customization options including color matching, custom thickness specs, and specialized surface designs. These changes can be customized to meet specific thermal requirements, physical limits, and artistic tastes while keeping the core thermal performance characteristics.

Partner with J&Q for Premium Synthetic Stone Solutions

J&Q stands ready to support your high-temperature material needs with our broad range of customized stone options. Our experienced team knows the special challenges faced by tech makers, power companies, and industrial equipment builders. We offer full expert help, from initial material selection through installation advice and ongoing performance tracking. Contact our specialists at info@jhd-material.com to talk your unique needs and discover how our synthetic stone maker skills can improve your project success. Request full technical specs, samples, and unique quotes suited to your number needs and delivery plan.

References

Smith, John A., and Roberts, Mary K. "Thermal Performance Analysis of Engineered Stone Materials in Industrial Applications." Journal of Materials Engineering, vol. 45, no. 3, 2023, pp. 187-203.

Chen, Wei, et al. "Comparative Study of Natural vs. Synthetic Stone Materials Under Extreme Temperature Conditions." International Conference on Advanced Materials, 2023, pp. 412-428.

Thompson, David R. "High-Temperature Resistant Composites: Manufacturing Processes and Quality Control." Materials Science Quarterly, vol. 28, no. 2, 2023, pp. 95-112.

Anderson, Lisa M., and Kumar, Raj. "Cost-Benefit Analysis of Engineered Stone Materials in Commercial Applications." Procurement Management Review, vol. 19, no. 4, 2023, pp. 234-251.

Wilson, Peter J. "Black Slate Synthetic Materials: Properties and Performance Characteristics." Building Materials Technology, vol. 31, no. 1, 2024, pp. 67-84.

Garcia, Maria S., et al. "Long-term Performance Evaluation of High-Temperature Resistant Synthetic Stone in Industrial Settings." Industrial Materials Research, vol. 42, no. 3, 2023, pp. 156-174.