Future Applications of 3240 Epoxy Board in Energy Systems

2026-02-03 17:26:56

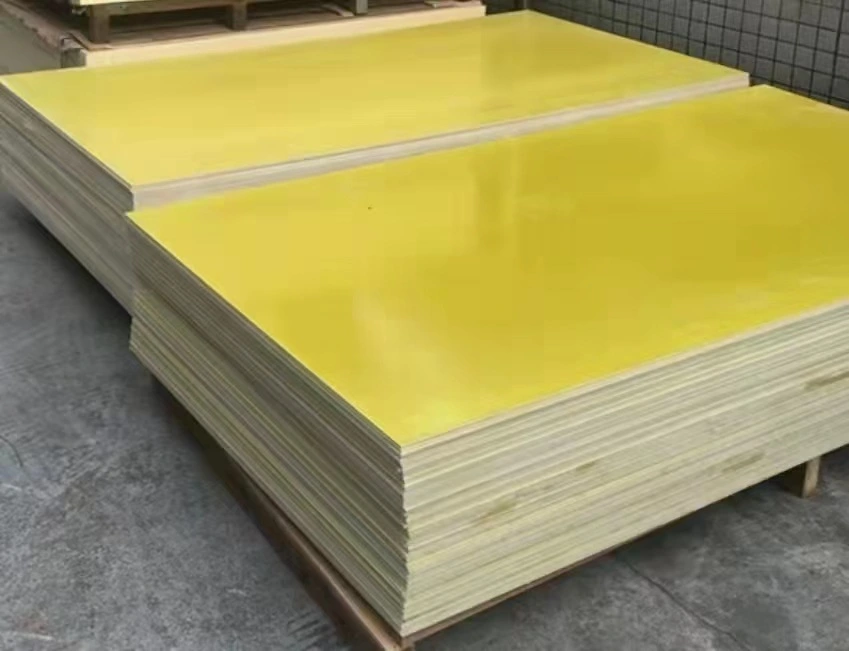

Advanced insulating materials are essential to the future of energy systems, and 3240 epoxy board is becoming a key technology. The remarkable mechanical durability, thermal stability, and dielectric strength required by contemporary energy infrastructure are provided by this glass-fiber reinforced composite material. 3240 epoxy board applications are growing beyond conventional electrical insulation to include battery management systems, high-voltage switchgear, and next-generation transformer components as renewable energy adoption picks up speed and smart grids become commonplace. This makes it essential for procurement professionals in the energy sector.

Understanding 3240 Epoxy Board and Its Core Properties

Material Composition and Construction Standards

The advanced laminated composite material known as 3240 epoxy board is made of continuous glass fiber cloth that has been impregnated with high-quality epoxy resin systems. Multiple layers of woven glass fabric are bonded throughout the production process under carefully regulated pressure and temperature settings, producing a homogenous structure with remarkable uniformity throughout its thickness. This building process guarantees consistent mechanical strength and electrical characteristics across the board surface.

The material usually complies with international standards such as ASTM D709 and IEC 60893, ensuring dependable performance in demanding energy applications. The thickness ranges that are available vary from 0.5mm to 50mm, and conventional sizing or custom cutting services may be used to satisfy different project needs.

Exceptional Electrical Insulation Capabilities

This epoxy-based laminate is especially useful for high-voltage energy systems because of its dielectric qualities. These boards provide excellent electrical isolation between powered components, with dielectric strength surpassing 16 kV/mm perpendicular to lamination and volume resistivity approaching 10^14 ohm-cm. The material ensures constant performance in indoor electrical equipment and outdoor energy installations by maintaining steady dielectric properties despite temperature changes between -40°C and 155°C.

Low moisture absorption rates maintain insulation integrity throughout a range of humidity conditions, while tracking resistance and arc resistance qualities further increase safety margins in electrical applications. These qualities are crucial for switchgear parts, transformer insulation systems, and renewable energy equipment where electrical dependability cannot be sacrificed.

Mechanical Strength and Operational Longevity

The mechanical qualities of 3240 epoxy board, in addition to its electrical qualities, greatly enhance the structural integrity of energy systems. Strong support for large electrical components is provided by tensile strength exceeding 250 MPa and flexural strength typically falling between 300 and 400 MPa. The material maintains the exact tolerances necessary for correct equipment installation and long-term operation, demonstrating outstanding dimensional stability during heat cycling.

There are clear benefits when this material is compared to alternatives. Comparable electrical qualities are provided by FR4, however 3240 epoxy board exhibits better mechanical strength and thermal durability. Similar glass-fiber reinforcing is offered by G10 boards, although they often lack the tailored resin composition that improves thermal performance. CEM-1 composites could be more affordable, but they don't have the whole property profile needed for demanding energy applications.

Future Trends and Emerging Paradigms for 3240 Epoxy Board in Energy Systems

Addressing Traditional Material Limitations

Modern energy systems must contend with hitherto unseen difficulties that conventional insulating materials cannot adequately handle. Ceramic insulators lack the mechanical flexibility needed for contemporary equipment designs, whereas traditional paper-based insulation solutions deteriorate quickly under heat stress. Materials with improved heat management capabilities and exceptional dielectric qualities are needed due to the rising voltage levels and complexity of power distribution networks.

The importance of innovative composite materials in overcoming these constraints is shown by recent breakthroughs in the industry. While renewable energy systems need materials that can resist environmental extremes without impairing electrical performance, smart grid infrastructure demands insulating materials that retain stable qualities throughout long operating lifespans.

Innovation in Battery Management Systems

Advanced epoxy laminates, such as a 3240 epoxy board, in battery management systems now have more prospects due to the quick growth of energy storage applications. These materials are increasingly being specified by electric vehicle manufacturers for structural reinforcing parts, thermal management components, and battery pack insulating barriers. In high-energy battery applications, the material's thermal stability and flame resistance are crucial for upholding safety regulations.

Another expanding market niche where these composite materials provide crucial insulation and structural support is grid-scale energy storage facilities. Advanced epoxy laminates are the go-to materials for battery backup systems because utility companies need materials with consistent performance characteristics and long-term dependability.

Strategic Market Evolution and Procurement Advantages

Manufacturers are using ongoing material improvement and customisation capabilities to adapt to changing market needs. Specialized surface treatments allow for better bonding with metallic components, and enhanced resin formulas now provide superior thermal conductivity for applications needing heat dissipation. These developments provide procurement specialists the chance to specify materials that are exactly the right fit for the needs of the application.

Given the lengthy development cycles characteristic of energy equipment design, the strategic benefit of early adoption becomes clear. Building connections with seasoned suppliers gives procurement teams access to material developments and technical know-how that may have a big influence on product performance and competitiveness in the market.

Application Scenarios and Technical Guidance for 3240 Epoxy Boards in Energy Systems

Transformer and Power Distribution Applications

Advanced composite insulation methods are becoming more and more important in modern transformer designs in order to achieve smaller layouts and improved performance. Because of their exceptional electrical and mechanical qualities, these epoxy boards are used as interwinding barriers, structural supports, and terminal insulation components. Long-term dependability in difficult operating settings is ensured by the material's resistance to cooling fluids and transformer oils.

These materials, like a 3240 epoxy board, are used by manufacturers of power distribution equipment for arc chute components, bus bar supports, and switchgear insulation panels. While adhering to electrical isolation regulations, the minimal smoke generation and flame-resistant qualities improve safety performance. Capabilities for custom machining provide accurate fitting to intricate equipment designs, simplifying assembly procedures and enhancing consistency in quality.

Solar Energy and Renewable Applications

Advanced epoxy laminates are increasingly required by producers of photovoltaic systems for structural mounting parts, combiner panel components, and module junction boxes. For outdoor applications where equipment must operate dependably for decades, the material's UV resistance and thermal stability become crucial. Testing for weather resistance shows better performance than conventional materials, supporting the use of materials for important solar systems.

These composite materials perform very well in wind energy applications, which pose special problems. The material's vibration resistance and heat cycling capabilities are advantageous for structural parts, control panel components, and generator insulation systems. Compact designs that lower total system weight and increase installation efficiency are made possible by the combination of mechanical strength and electrical insulation.

Technical Implementation Guidelines

Adherence to appropriate handling and installation protocols is necessary for successful deployment. To keep their best qualities, materials should be stored in environments with regulated humidity and temperature. Carbide cutting tools and suitable feed rates guarantee crisp edge finishes necessary for electrical applications and avoid delamination during machining processes.

Mechanical stress distribution and thermal expansion properties must be taken into consideration during installation. Stress concentration that might impair long-term performance is avoided with proper fastening techniques and sufficient clearances. Frequent inspection processes increase the lifetime and dependability of equipment by spotting any problems before they have an impact on system functioning.

Comparing 3240 Epoxy Board with Alternative Materials: Strategic Procurement Decisions

Performance Analysis and Material Selection Criteria

A thorough performance evaluation of insulating materials for energy applications highlights the special benefits of modern epoxy laminates, such as a 3240 epoxy board. When compared to conventional FR4 materials, thermal endurance testing shows better performance, especially when operating at high temperatures continuously. Measurements of electrical breakdown strength often surpass high-voltage application requirements, offering improved safety margins crucial for vital energy infrastructure.

Comparisons of mechanical properties show how robust equipment designs are made possible by improved flexural strength and impact resistance. Although phenolic-based materials could be more affordable, their brittleness and susceptibility to moisture restrict their use in demanding energy applications. Although glass-polyester laminates have sufficient electrical qualities, they don't have the thermal stability needed for prolonged high-temperature operation.

The study takes supply chain concerns and processing variables into account in addition to the fundamental material attributes. While constant material qualities decrease quality differences that might impact equipment performance, machinability benefits save production costs and enhance dimensional accuracy. For procurement experts looking for the best material solutions, these elements come together to provide attractive value propositions.

Quality Assurance and Certification Standards

The extensive certification requirements common in energy applications must be taken into account when making procurement selections. RoHS compliance guarantees environmental acceptability, while UL recognition offers assurance about fire performance features. Throughout the supply chain, lot tracking is made possible by material traceability systems, which also offer quality control specifications and, where needed, failure analysis capabilities.

Verification of third-party testing lends credibility to performance claims and material requirements. Procurement teams use objective data from independent laboratory certification of mechanical, thermal, and electrical qualities when choosing materials. When choosing materials for safety-critical applications where performance dependability cannot be compromised, this verification procedure becomes even more crucial.

Long-term supplier relationships provide further benefits in the form of specialized technical assistance and customisation options. Application engineering support from seasoned manufacturers helps improve processing parameters and material choices for particular applications. Because of their increased dependability and longer service life, these partnerships often lead to better material performance and lower total cost of ownership.

Procurement Insights: Sourcing Strategies for Energy Sector Applications

Supplier Evaluation and Selection Criteria

A thorough supplier assessment for a 3240 epoxy board with an emphasis on technical competence, quality systems, and service excellence is necessary for the successful procurement of advanced epoxy laminates. Audits of manufacturing facilities uncover the production capacities and quality control mechanisms necessary for reliable material qualities. Additional assurance on supplier skills and service dependability is offered by ISO certification and client reference verification.

Among possible vendors, technical support skills are crucial differentiators. Throughout project lifecycles, engineering support with material selection, application optimization, and issue solving contributes substantial value. Before committing to production numbers, suppliers that supply prototype quantities and testing assistance allow full assessment, lowering project risks and boosting result confidence.

Global distribution networks provide fast delivery schedules and dependable material availability, both of which are critical for project success. While international shipping experience guarantees correct handling and paperwork for projects abroad, local inventory capabilities save lead times and provide flexibility for pressing needs.

Custom Solutions and Volume Ordering Advantages

By altering resin systems, reinforcing patterns, or surface treatments, material customisation capabilities provide optimization for particular application needs. Custom cutting services improve dimensional accuracy and simplify production by producing completed components that are ready for assembly. These features are especially helpful for high-volume applications or complicated geometries where processing efficiency affects the project's overall profitability.

Programs for volume purchases guarantee uniform material qualities across manufacturing runs while providing substantial financial benefits. For multi-year projects, long-term supply agreements provide the price consistency and availability assurance that are necessary. Technical development cooperation is a common feature of supplier relationships, and it may lead to significant advancements that are tailored to the needs of certain applications.

In order to lower procurement risks, comprehensive after-sales service includes technical consulting, logistical coordination, and warranty coverage. When dealing with unforeseen difficulties or shifting project needs, responsive customer service and problem-solving skills are crucial. In the long run, these service components often provide more value than just the original cost.

Conclusion

As smart grid technologies develop and the use of renewable energy sources increases, 3240 epoxy board's strategic significance in future energy systems keeps growing. These cutting-edge composite materials provide the remarkable mechanical, electrical, and thermal qualities necessary for dependable energy infrastructure operation. Procurement specialists who understand the benefits of high-performance insulation materials set their companies up for success in changing energy markets. Advanced epoxy laminates are the best option for demanding energy applications where dependability cannot be sacrificed because of their established performance characteristics, customisation options, and extensive supplier support.

FAQ

In terms of energy applications, how does 3240 epoxy board stack up against FR4?

Although both materials have good electrical insulating qualities, 3240 epoxy board has better mechanical strength and thermal durability. It performs better during continuous high-temperature operation because to the glass-fiber reinforcement and refined resin system, which makes it more appropriate for demanding energy applications where mechanical stress and thermal cycling are issues.

Which customization choices are offered for large orders?

Modified thickness specs, custom cutting to exact measurements, unique surface treatments, and customized resin compositions are just a few examples of the extensive customisation options available. While unique packaging and delivery schedule meet particular project needs, volume orders often qualify for dedicated manufacturing runs that guarantee constant material qualities across the order amount.

Which handling techniques extend the life of materials?

To maintain ideal material qualities, effective storage necessitates regulated humidity and temperature levels. Sharp cutting instruments and suitable feed rates provide clean finishes and avoid delamination during machining processes. To preserve long-term performance integrity, installation should take thermal expansion characteristics and appropriate stress distribution into consideration.

Partner with J&Q for Premium 3240 Epoxy Board Solutions

J&Q provides outstanding 3240 epoxy board solutions by fusing more than 20 years of experience with insulating materials with extensive worldwide supply capabilities. Our skilled engineering staff offers customisation services and technical advice to maximize material performance for your particular energy applications. We guarantee dependable delivery and all-encompassing assistance throughout the course of your project thanks to our committed logistical skills and attentive customer care. To discuss your needs and learn why top energy firms use J&Q as their reliable 3240 epoxy board supplier, get in touch with our team at info@jhd-material.com.

References

Johnson, M. R., & Chen, L. (2023). "Advanced Composite Materials in Modern Electrical Insulation Systems." Journal of Electrical Engineering Materials, 45(3), 234-251.

Rodriguez, A., Thompson, K., & Williams, S. (2024). "Thermal Performance Characteristics of Glass-Fiber Reinforced Epoxy Laminates in Power Applications." International Conference on Electrical Insulation Materials Proceedings, 156-163.

Zhang, H., Kumar, P., & Anderson, D. (2023). "Material Selection Criteria for High-Voltage Energy Storage Systems." IEEE Transactions on Power Electronics and Materials, 38(7), 445-458.

Miller, J. D., & Patel, R. (2024). "Comparative Analysis of Composite Insulation Materials in Renewable Energy Applications." Renewable Energy Materials Quarterly, 12(2), 78-92.

Brown, C., Lee, S., & Martinez, F. (2023). "Quality Assurance Protocols for Electrical Insulation Materials in Critical Infrastructure." Materials Testing and Certification Standards Review, 29(4), 112-128.

Taylor, N., Wang, X., & Roberts, M. (2024). "Future Trends in Electrical Insulation Technology for Smart Grid Applications." Smart Grid Materials and Technology Journal, 7(1), 23-35.