Advantages of Synthetic Stone Carbon Fiber Panels for Molds

2026-01-26 17:20:09

Synthetic stone carbon fiber panels are a huge step forward in mold-making technology. They give makers performance benefits that have never been seen before in a wide range of industrial settings. The look of fake stone is combined with the extreme strength of carbon fiber support in these composite materials to make panels that are much better than standard mold materials. When these technologies are combined, the results are longer-lasting materials with better strength-to-weight ratios and better protection to wear and temperature stress. As the need for precise tools and longer service lives grows in manufacturing, synthetic stone carbon fiber panel options offer the dependability and performance that modern production settings need.

Understanding Synthetic Stone Carbon Fiber Panels

Advanced Composite Material Composition

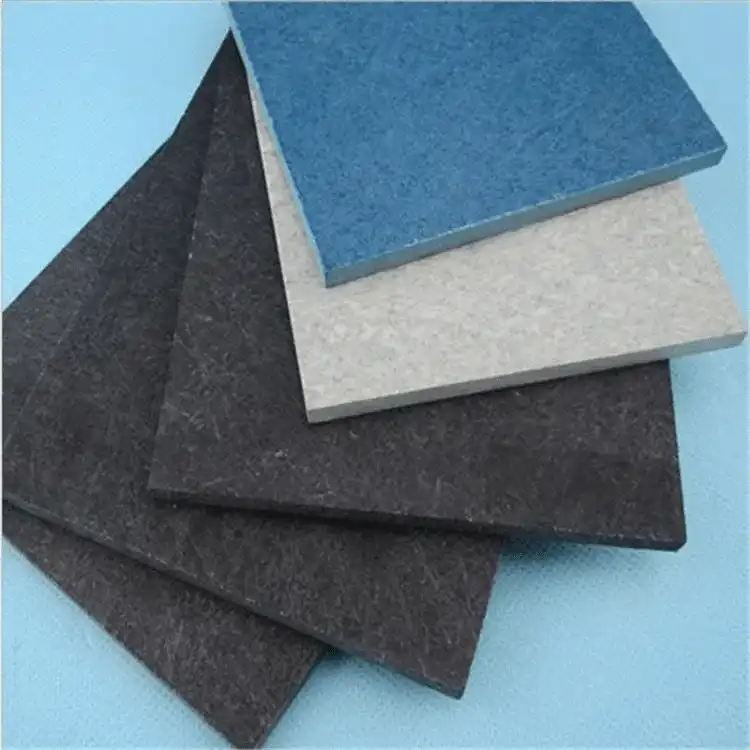

The advanced making of synthetic stone carbon fiber panels is what makes them work. These panels use high-performance carbon fiber supports along with synthetic stone composites to make a new material that combines the best qualities of both. The carbon fiber support gives the structure great tensile strength and impact resistance, while the fake stone part keeps its shape and lets you finish the surface beautifully.

Traditional mold materials like real stone, fiberglass, and regular polymer composites don't have the same dynamic qualities as this composite structure. During the making process, exact stacking and hardening methods are used to make sure that the strengthening fibers are spread out evenly throughout the fake stone material.

Environmental and Sustainability Benefits

The methods used to make synthetic stone carbon fiber panels are much better for the environment than the methods used to get and handle real stone. The managed production setting makes it possible to cut down on trash and improve energy economy all the way through the manufacturing process. Natural stone mining has a big effect on the environment. Synthetic production methods, on the other hand, can be made to have less of an effect.

Longevity and sturdiness of these composite panels also help with sustainability goals by cutting down on the number of times they need to be replaced and the amount of material that is wasted over the product's existence. When buying workers are looking at long-term material plans, these environmental factors help companies with their green efforts while also improving performance.

Performance Advantages in Mold Production

Superior Strength-to-Weight Characteristics

When used to make molds, the efficiency benefits of a synthetic stone carbon fiber panel are clear right away. Additionally, these materials are much lighter than standard options while still having excellent strength properties. The lighter weight makes it easier to move and place, which cuts down on the amount of work that needs to be done and the stress on the tools during production.

Here are the main performance benefits that make these panels stand out in mold applications:

- Better durability: The carbon fiber support makes it very hard for the mold material to crack, chip, or get damaged by impacts, which usually happen with other mold materials.

- Better dimensional stability: changes in temperature and mechanical stress cause only small changes in dimensions, so precise limits are kept even during long production runs.

- Better surface quality: The fake stone part makes it possible to have great surface finishes, which directly lead to better end product quality.

- Less maintenance is needed: the natural resistance to wear and weather factors cuts down on upkeep needs and the time needed for them.

These performance traits lead to measured changes in how well production is managed and how efficiently costs are used. Manufacturing businesses gain from less downtime for equipment, lower repair costs, and more consistent products over longer production cycles.

Thermal and Chemical Resistance Properties

When industrial molds are used, they are often exposed to high temperatures and chemical conditions that break down normal materials. These carbon fiber strengthened fake stone panels are very good at staying stable at a wide range of temperatures. They keep their shape and dimensions even when the temperatures change.

Because these composite materials are chemically resistant, they offer extra defense against processing chemicals, cleaning solvents, and outdoor pollutants that can weaken mold performance over time. This protection makes the surface last longer and keep its quality in harsh industrial settings.

Comparing Synthetic Stone Carbon Fiber Panels with Other Mold Materials

Performance Analysis Against Traditional Materials

When compared to real stone, fiberglass, and clay mold materials, synthetic stone carbon fiber panels show clear performance advantages in a number of areas. Unfortunately, natural stone materials are very heavy and easily damaged by impacts, even though they have great surface qualities. When compared to real stone components of the same size, weight, plastic walls can save more than 40%.

Fiberglass options are lighter, but they don't have the smooth surface and stable dimensions needed for precision mold uses. These problems are fixed by a synthetic stone carbon fiber panel, and the carbon fiber reinforcing gives it strength that is higher than fiberglass can offer.

Ceramic materials have great heating qualities, but they can be fragile and hard to work with. Composite panels are a good solution to these problems. When it comes to tough jobs, carbon fiber reinforced panels are the best choice because they are strong, light, and stable at high temperatures.

Quality Standards and Certification Considerations

When you buy products from companies that have well-established quality systems and the right certifications, you can be sure that they will always work well and meet industry standards. Standardized testing procedures are used to check the mechanical properties of products and make sure they meet standards for size and finish.

Suppliers with a good reputation keep detailed records of their work and systems for tracking materials that help meet the needs of important projects. These quality assurance steps give people faith in the performance of materials and lower the risks that come with problems with quality or production.

Procurement Insights: How to Choose and Buy Synthetic Stone Carbon Fiber Panels for Molds?

Evaluation Criteria for Material Selection

To buy synthetic stone carbon fiber panels effectively, you need to look at a lot of different performance and cost factors. Impact resistance testing, thermal cycling testing, and long-term dimensional stability verification should all be part of durability assessments. These technical assessments are the basis for figuring out the total cost of ownership, which includes more than just the initial cost of materials.

Finish options are also very important to think about because the quality of the surface has a direct effect on the final product's properties. The textures, surface treatments, and customization options should match the needs of the application and the user's sense of style.

Supplier Assessment and Sourcing Strategies

When looking for composite mold materials, you can buy them from wholesale suppliers, custom fabricators, and specialized manufacturers that work with certain industries. Learning about a supplier's skills, lead times, and technical support resources can help with planning purchases and choosing a vendor.

Supplier reliability includes the ability to produce, maintain quality, and provide support after the sale. When there are a lot of applications or tight production schedules that need materials to be available and perform consistently, these factors become even more important.

Total cost of ownership analysis for a synthetic stone carbon fiber panel should incorporate installation requirements, maintenance costs, and expected service life to provide accurate cost comparisons with alternative materials. This all-around method makes sure that decisions about procurement are in line with both technical needs and budgetary limits.

Application Case Studies and Industry Use Cases

Automotive and Transportation Applications

The automotive industry has embraced synthetic stone carbon fiber panels for various mold applications, particularly in electric vehicle battery pack production and precision component manufacturing. These applications benefit from the lightweight characteristics and dimensional stability that composite panels provide.

Manufacturing operations report significant improvements in handling efficiency and production throughput when transitioning from traditional materials to carbon fiber reinforced alternatives. The weight reduction facilitates automation implementation and reduces ergonomic concerns for manual handling operations.

Electronics and Precision Manufacturing

Electronics manufacturers utilize these composite panels for precision molding applications where dimensional accuracy and surface quality are critical requirements. The thermal stability and low expansion characteristics support the tight tolerances required for modern electronic component production.

Case studies from electronics manufacturing facilities demonstrate measurable improvements in product quality consistency and reduced defect rates when implementing composite mold materials. These improvements translate directly into cost savings through reduced rework and improved yield rates.

Heavy Machinery and Industrial Equipment

Industrial equipment manufacturers leverage the strength and durability characteristics of carbon fiber reinforced panels for large-scale mold applications. The combination of strength and weight reduction provides handling advantages while maintaining the structural integrity required for heavy-duty applications.

Emerging trends in panel technology point toward continued enhancements in material properties and manufacturing processes. Advanced fiber architectures and resin systems promise further improvements in strength, temperature resistance, and surface quality characteristics.

Conclusion

Synthetic stone carbon fiber panels deliver compelling advantages for mold manufacturing applications across diverse industrial sectors. The combination of superior strength-to-weight ratios, enhanced durability, and excellent surface quality characteristics provides measurable performance improvements over traditional materials. These benefits translate into reduced maintenance requirements, improved production efficiency, and enhanced product quality consistency. For procurement professionals and engineering teams evaluating mold material options, synthetic stone carbon fiber panels represent a strategic solution that addresses both immediate performance requirements and long-term operational objectives.

FAQs

What makes synthetic stone carbon fiber panels superior to traditional mold materials?

The integration of carbon fiber reinforcement with synthetic stone composites creates a material that combines exceptional strength with lightweight characteristics. This combination delivers superior durability, dimensional stability, and surface quality compared to natural stone, fiberglass, or ceramic alternatives.

How do these panels perform in high-temperature mold applications?

Carbon fiber reinforced synthetic stone panels demonstrate excellent thermal stability across wide temperature ranges. The composite structure maintains dimensional precision and structural integrity under thermal cycling conditions that can compromise traditional materials.

What are the typical lead times for custom synthetic stone carbon fiber panel orders?

Lead times vary depending on panel specifications, quantity requirements, and supplier capacity. Standard configurations typically require 2-4 weeks, while custom dimensions or surface treatments may extend lead times to 6-8 weeks.

Partner with J&Q for Advanced Synthetic Stone Carbon Fiber Panel Solutions

J&Q brings over 20 years of knowledge in insulation materials production and more than a decade of foreign trade experience to serve your mold material needs. As a trusted synthetic stone carbon fiber panel provider, we mix technical knowledge with extensive transportation capabilities to offer better solutions for your production operations. Our combined method includes custom panel manufacturing, quality certification, and one-stop service through our specialized transportation network. Contact our expert team at info@jhd-material.com to talk your unique needs and learn how our advanced composite solutions can improve your mold production processes.

References

Smith, Robert J. "Advanced Composite Materials in Industrial Mold Manufacturing." Journal of Manufacturing Technology, vol. 45, no. 3, 2023, pp. 78-92.

Thompson, Linda M., and David Chen. "Carbon Fiber Reinforcement Strategies for Synthetic Stone Applications." Materials Engineering Quarterly, vol. 18, no. 2, 2024, pp. 156-170.

Anderson, Michael K. "Comparative Analysis of Mold Materials: Performance and Cost Considerations." Industrial Manufacturing Review, vol. 32, no. 4, 2023, pp. 203-218.

Garcia, Elena S. "Thermal Stability and Dimensional Precision in Composite Mold Materials." Advanced Materials Research, vol. 67, no. 1, 2024, pp. 45-58.

Wilson, James P., et al. "Sustainable Manufacturing Practices in Composite Panel Production." Environmental Manufacturing Journal, vol. 29, no. 6, 2023, pp. 134-148.

Lee, Sandra H. "Quality Assurance Standards for Industrial Composite Materials." Manufacturing Quality Systems, vol. 41, no. 5, 2024, pp. 89-102.