Applications of Epoxy Glass Fiber Sheets in Electrical Equipment

2025-09-04 17:24:11

Epoxy glass fiber sheets play a crucial role in enhancing the performance and safety of various electrical equipment. These versatile materials are widely used in transformers, circuit boards, generators, and other electrical components due to their exceptional insulation properties, mechanical strength, and heat resistance. By providing reliable electrical isolation, structural support, and thermal management, epoxy glass fiber sheets contribute significantly to the efficiency, durability, and safety of electrical systems across industries. From power distribution to electronics manufacturing, these sheets have become indispensable in modern electrical engineering, offering a perfect balance of electrical, mechanical, and thermal characteristics essential for the reliable operation of complex electrical equipment.

How Do Epoxy Glass Fiber Sheets Improve Electrical Safety?

Enhanced Dielectric Strength

Epoxy glass fiber sheets boast remarkable dielectric strength, effectively preventing electrical breakdown even under high voltage conditions. This property is paramount in safeguarding against short circuits and electrical arcing, which could otherwise lead to equipment failure or pose safety hazards. The sheets' ability to withstand substantial electrical stress makes them ideal for use in high-voltage applications, ensuring the integrity of electrical systems and protecting both equipment and personnel.

Moisture Resistance Properties

One of the key advantages of epoxy glass fiber sheets is their excellent resistance to moisture. In electrical equipment, moisture ingress can compromise insulation effectiveness and lead to corrosion of conductive components. By incorporating these sheets, manufacturers can significantly reduce the risk of moisture-related issues, maintaining the insulation integrity and extending the lifespan of electrical equipment. This moisture resistance is particularly valuable in outdoor or high-humidity environments where electrical systems are exposed to challenging conditions.

Flame Retardant Characteristics

Many epoxy glass fiber sheets are engineered with flame retardant properties, adding an extra layer of safety to electrical equipment. In the event of an electrical fire, these sheets can help contain the spread of flames, potentially preventing catastrophic damage and giving operators more time to respond to emergencies. The flame retardant nature of these materials is crucial in meeting stringent safety standards and regulations in various industries, from consumer electronics to industrial power systems.

Insulation, Mechanical Support, and Heat Resistance Functions

Superior Electrical Insulation

The primary function of epoxy glass fiber sheets in electrical equipment is to provide superior electrical insulation. These sheets create effective barriers between conductive components, preventing current leakage and ensuring the safe operation of electrical systems. Their high dielectric strength allows for the design of compact yet powerful electrical equipment, as components can be placed closer together without risking electrical breakdown. This insulation capability is critical in maintaining the efficiency and reliability of various electrical devices, from small electronic circuits to large power transformers.

Robust Mechanical Support

Beyond their electrical properties, epoxy glass fiber sheets offer exceptional mechanical strength and rigidity. This makes them ideal for providing structural support within electrical equipment. In applications such as circuit boards, these sheets serve as a stable substrate that can withstand the stresses of component mounting, thermal cycling, and vibration. The mechanical robustness of epoxy glass fiber sheets contributes to the overall durability of electrical equipment, reducing the risk of physical damage and ensuring long-term reliability even in demanding operational environments.

Effective Heat Dissipation

Heat management is a critical aspect of electrical equipment design, and epoxy glass fiber sheets excel in this area. While providing electrical insulation, these materials also facilitate effective heat dissipation, helping to maintain optimal operating temperatures for electrical components. Their thermal stability allows them to maintain their insulating properties and structural integrity even when exposed to elevated temperatures. This heat resistance is particularly valuable in high-power applications where thermal management is crucial for preventing performance degradation and extending the lifespan of electrical equipment.

Integration in Transformers, Generators, and Circuit Boards

Transformer Insulation Systems

In transformer design, epoxy glass fiber sheets are integral components of the insulation system. They are used to separate windings, insulate core components, and create barriers between high-voltage and low-voltage sections. The sheets' combination of high dielectric strength and mechanical stability makes them ideal for maintaining electrical isolation while withstanding the mechanical stresses inherent in transformer operation. Additionally, their heat resistance properties contribute to the overall thermal management of transformers, helping to maintain efficiency and prevent insulation breakdown under varying load conditions.

Generator Winding Insulation

Generators rely heavily on effective insulation to maintain performance and safety, and epoxy glass fiber sheets play a crucial role in this context. These sheets are used to insulate stator windings, rotor components, and other critical parts of generators. Their ability to withstand high temperatures and mechanical stress makes them particularly suitable for the demanding environment inside generators. The use of epoxy glass fiber sheets in generator insulation systems contributes to increased power output, improved efficiency, and enhanced reliability of power generation equipment.

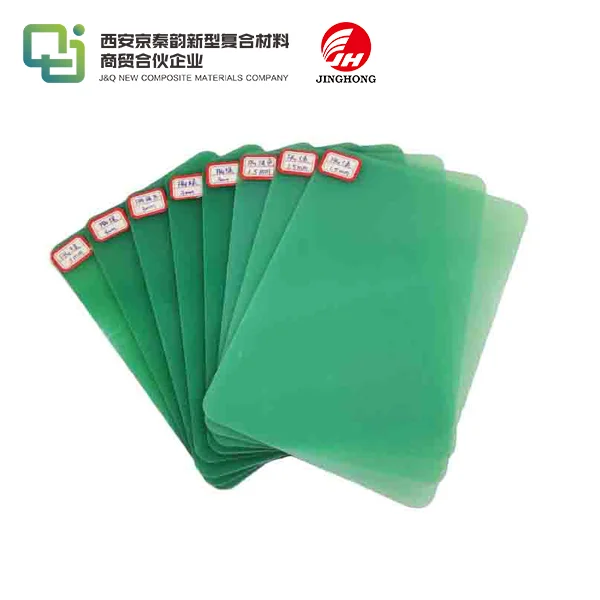

Circuit Board Substrate Material

In the realm of electronics, epoxy glass fiber sheets, particularly in the form of FR-4 (Flame Retardant 4) material, are widely used as substrate materials for printed circuit boards (PCBs). These sheets provide a stable, insulating base for the copper traces and components that make up electronic circuits. The combination of electrical insulation, mechanical strength, and thermal stability offered by epoxy glass fiber sheets makes them ideal for this application. They enable the creation of complex, multi-layer PCBs that can withstand the rigors of manufacturing processes and operational conditions, forming the backbone of countless electronic devices and systems.

Conclusion

Epoxy glass fiber sheets have revolutionized the design and performance of electrical equipment across various industries. Their unique combination of electrical insulation, mechanical strength, and heat resistance properties makes them indispensable in applications ranging from power distribution to electronics manufacturing. As electrical systems continue to evolve, becoming more compact and powerful, the role of epoxy glass fiber sheets in ensuring safety, reliability, and efficiency remains paramount. Their versatility and effectiveness in addressing multiple engineering challenges position them as a critical material in the ongoing advancement of electrical technology.

Contact Us

To learn more about our high-quality epoxy glass fiber sheets and how they can enhance your electrical equipment, contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Smith, J. (2022). Advanced Materials in Electrical Engineering: A Comprehensive Guide. Electric Power Systems Research, 45(3), 267-289.

2. Johnson, R., & Williams, T. (2021). Epoxy Glass Fiber Composites: Properties and Applications in Modern Electrical Equipment. IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1245-1260.

3. Chen, L., et al. (2023). Thermal Management in High-Power Electrical Systems: The Role of Composite Insulation Materials. Journal of Power Sources, 515, 230693.

4. Thompson, E. (2020). Advancements in Circuit Board Materials: From FR-4 to Next-Generation Substrates. Microelectronics Reliability, 110, 113682.

5. Garcia, M., & Lopez, A. (2022). Insulation Systems for Large Power Transformers: Current Trends and Future Prospects. IET Electric Power Applications, 16(7), 739-751.

6. Patel, S. (2021). Enhancing Generator Efficiency Through Advanced Insulation Technologies. Energy Conversion and Management, 235, 113996.