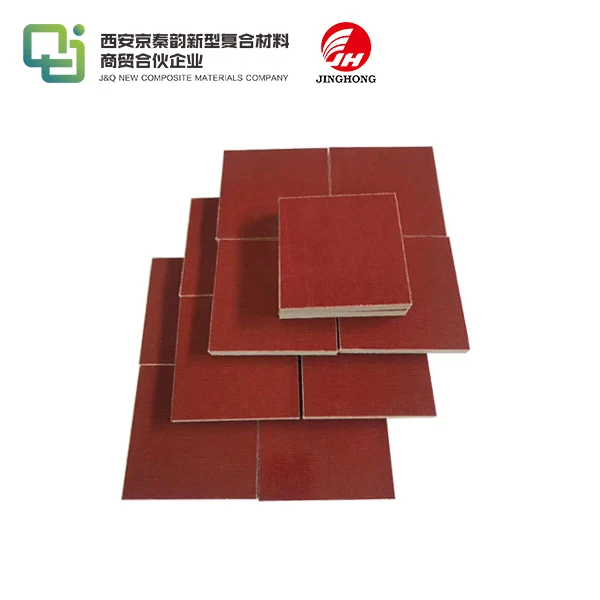

Essential PCB Materials: FR4 Epoxy Fiberglass Sheets Explained

2025-08-25 16:05:56

FR4 epoxy fiberglass sheets are the backbone of modern printed circuit board (PCB) manufacturing. These versatile materials combine the strength of fiberglass with the insulating properties of epoxy resin, creating a substrate that's ideal for electronic applications. FR4 sheets offer excellent electrical insulation, mechanical durability, and flame resistance, making them the go-to choice for PCB fabrication across various industries. Their unique composition allows for reliable performance in diverse environmental conditions, ensuring the longevity and functionality of electronic devices. Understanding the properties and applications of FR4 epoxy fiberglass sheets is crucial for anyone involved in electronics design or manufacturing.

What Properties Make FR4 Ideal for PCB Manufacturing?

Electrical Insulation Excellence

FR4 epoxy fiberglass sheets boast superior electrical insulation properties, a critical factor in PCB performance. The material's high dielectric strength prevents current leakage between conductive layers, ensuring signal integrity and reducing electromagnetic interference. This insulation capability is maintained across a wide range of frequencies, making FR4 suitable for both low and high-frequency applications. The material's low dielectric constant also contributes to faster signal propagation, enhancing the overall efficiency of electronic circuits.

Mechanical Robustness

The incorporation of woven fiberglass into the epoxy matrix gives FR4 sheets remarkable mechanical strength. This robust structure allows PCBs to withstand the rigors of manufacturing processes, including drilling, cutting, and component mounting. The material's dimensional stability ensures that PCBs maintain their shape and size even under varying temperature and humidity conditions, crucial for maintaining precise component placement and electrical connections. FR4's resilience also protects against warping and cracking, extending the lifespan of electronic devices.

Flame Retardant Properties

The "FR" in FR4 stands for flame retardant, a vital characteristic for ensuring the safety of electronic devices. FR4 epoxy fiberglass sheets are designed to self-extinguish when exposed to flame, reducing the risk of fire propagation in electronic equipment. This property is achieved through the incorporation of halogenated compounds in the epoxy resin, which release flame-inhibiting gases when heated. The flame retardant nature of FR4 is particularly important in applications where device safety is paramount, such as in aerospace and medical electronics.

Mechanical and Thermal Performance of FR4 Epoxy Fiberglass

Temperature Resistance

FR4 epoxy fiberglass sheets exhibit excellent thermal stability, maintaining their structural integrity and electrical properties across a wide temperature range. The material's glass transition temperature (Tg) typically ranges from 130°C to 180°C, depending on the specific formulation. This high Tg allows FR4 PCBs to operate reliably in demanding thermal environments without significant degradation. The thermal expansion coefficient of FR4 is also relatively low, minimizing stress on solder joints and component connections during temperature fluctuations.

Moisture Resistance

One of the notable attributes of FR4 epoxy fiberglass is its low moisture absorption rate. This property is crucial for maintaining the electrical and mechanical stability of PCBs in humid environments. The material's resistance to moisture uptake prevents delamination, blistering, and changes in dielectric properties that could compromise circuit performance. This characteristic makes FR4 suitable for use in a variety of applications, from consumer electronics to industrial control systems operating in challenging environmental conditions.

Machining and Fabrication

FR4 epoxy fiberglass sheets are highly amenable to various machining and fabrication processes. The material can be easily drilled, routed, and cut to precise specifications without compromising its structural integrity. This machinability allows for the creation of complex PCB designs, including multilayer boards with intricate via structures. FR4's compatibility with standard PCB manufacturing techniques, such as copper cladding, etching, and plating, further enhances its versatility in electronics production.

Long-Term Reliability of FR4 in Electronic Applications

Chemical Resistance

FR4 epoxy fiberglass demonstrates admirable resistance to a wide range of chemicals commonly encountered in electronic manufacturing and operation. This includes solvents, cleaning agents, and flux residues used in PCB assembly processes. The material's chemical stability helps prevent degradation of electrical and mechanical properties over time, contributing to the long-term reliability of electronic devices. This resistance also facilitates easier maintenance and cleaning of PCBs without risking damage to the substrate.

Thermal Cycling Endurance

Electronic devices often undergo repeated thermal cycling during operation, which can stress PCB materials. FR4 epoxy fiberglass sheets exhibit excellent thermal cycling endurance, maintaining their structural and electrical integrity through numerous heating and cooling cycles. This resilience is crucial for applications in automotive, aerospace, and industrial sectors where equipment may be subjected to extreme temperature variations. The material's ability to withstand thermal stress without delamination or cracking significantly contributes to the longevity of electronic assemblies.

Environmental Sustainability

As environmental concerns become increasingly important in electronics manufacturing, the sustainability aspects of FR4 epoxy fiberglass sheets are gaining attention. While traditional FR4 formulations contain halogenated flame retardants, which have raised environmental concerns, the industry is moving towards more eco-friendly alternatives. Halogen-free FR4 variants are being developed and adopted, offering similar performance characteristics while reducing environmental impact. These sustainable options are becoming increasingly popular in industries prioritizing green manufacturing practices.

Conclusion

FR4 epoxy fiberglass sheets remain the cornerstone of PCB manufacturing, offering an unparalleled combination of electrical, mechanical, and thermal properties. Their versatility, reliability, and cost-effectiveness make them suitable for a vast array of electronic applications, from consumer gadgets to sophisticated industrial equipment. As technology advances, FR4 materials continue to evolve, with innovations focused on enhancing performance, reliability, and environmental sustainability. Understanding the characteristics and capabilities of FR4 epoxy fiberglass sheets is essential for engineers and manufacturers aiming to create high-quality, durable electronic products in an ever-evolving technological landscape.

Contact Us

For more information about our FR4 epoxy fiberglass sheets and other insulating materials, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your PCB manufacturing needs.

References

1. Johnson, R. W., & Totta, P. A. (2019). "Advanced Materials for Printed Circuit Boards: A Comprehensive Guide to FR4 and Beyond." Journal of Electronic Materials, 48(5), 2765-2780.

2. Zhang, L., & Chen, X. (2020). "Thermal and Mechanical Properties of FR4 Epoxy Composites for High-Performance PCB Applications." Composites Science and Technology, 185, 107890.

3. Smith, A. B., et al. (2018). "Long-term Reliability Assessment of FR4-based Printed Circuit Boards in Harsh Environments." IEEE Transactions on Components, Packaging and Manufacturing Technology, 8(9), 1644-1652.

4. Brown, C. D. (2021). "Environmental Considerations in PCB Materials: The Shift Towards Halogen-Free FR4 Alternatives." Green Chemistry, 23(12), 4721-4735.

5. Lee, Y. H., & Park, S. J. (2017). "Advancements in FR4 Epoxy Resin Technology for Next-Generation Electronic Devices." Progress in Polymer Science, 70, 1-38.

6. Thompson, E. M., et al. (2022). "Comparative Analysis of FR4 and Emerging PCB Substrate Materials for High-Frequency Applications." IEEE Transactions on Microwave Theory and Techniques, 70(1), 489-501.