Where FR4 Laminate is Used in Aerospace Electronics?

2025-08-12 11:41:03

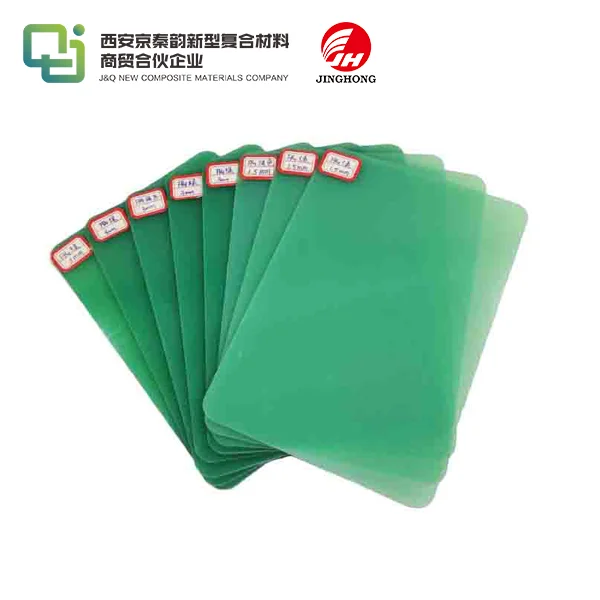

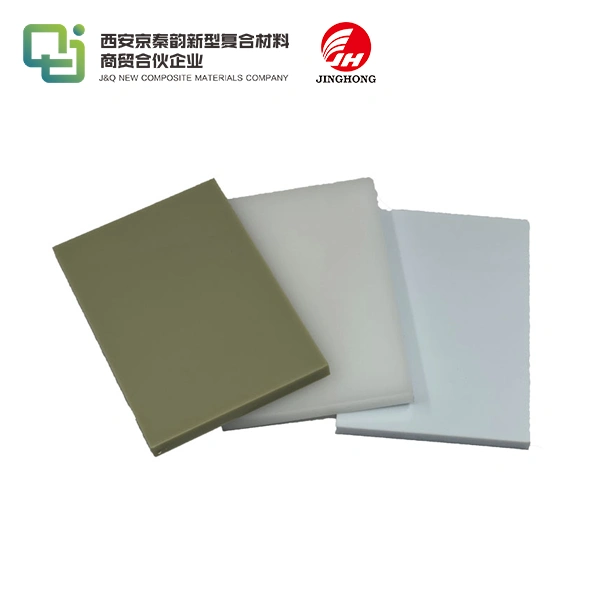

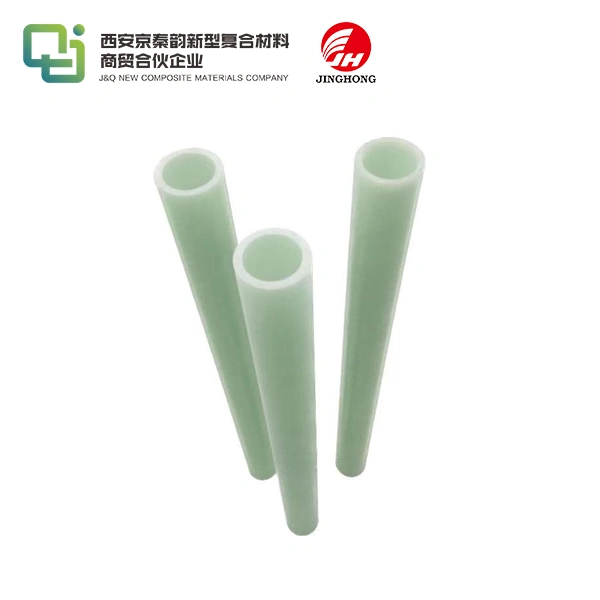

FR4 epoxy laminate, a versatile epoxy resin and fiberglass composite, plays a crucial role in aerospace electronics. It is extensively used in avionics systems, satellite components, and various onboard electronic devices. FR4's unique combination of electrical insulation, mechanical strength, and flame-retardant properties makes it ideal for printed circuit boards (PCBs) in flight control systems, communication equipment, and navigation instruments. Its resistance to extreme temperatures and vibrations ensures reliable performance in harsh aerospace environments. FR4 laminate is also utilized in radar systems, power distribution units, and cockpit displays, providing a stable substrate for complex electronic circuitry while meeting stringent aerospace safety standards.

Why Is FR4 Selected for Avionics and Satellite Systems?

Superior Electrical Properties

FR4 epoxy laminate boasts exceptional electrical insulation characteristics, making it an optimal choice for avionics and satellite systems. Its high dielectric strength ensures minimal signal loss and interference, crucial for maintaining clear communication and precise data transmission in aerospace applications. The material's low dielectric constant and dissipation factor contribute to improved signal integrity, enabling faster data processing and reducing electromagnetic interference in complex avionics systems.

Flame Retardant Capabilities

The inherent flame-retardant properties of FR4 laminate are paramount in aerospace electronics. This material meets stringent fire safety regulations, significantly reducing the risk of fire propagation in the event of an electrical malfunction. The self-extinguishing nature of FR4 provides an additional layer of safety in oxygen-rich environments, which is critical for both aircraft and spacecraft operations. These flame-retardant capabilities help protect vital electronic systems and, by extension, the safety of crew and passengers.

Dimensional Stability

Aerospace electronics demand materials with excellent dimensional stability, and FR4 laminate excels in this aspect. It maintains its shape and size across a wide range of temperatures, crucial for the precise alignment of electronic components in PCBs. This stability ensures consistent performance of avionics and satellite systems, even when subjected to extreme temperature fluctuations encountered during flight or in orbit. The minimal thermal expansion of FR4 helps prevent stress on solder joints and component connections, enhancing the overall reliability of aerospace electronic systems.

High Reliability and Thermal Performance in Flight Conditions

Resistance to Extreme Temperatures

FR4 epoxy laminate demonstrates remarkable resilience in the face of extreme temperature variations encountered in aerospace environments. It maintains its structural integrity and electrical properties across a broad temperature range, from the frigid cold of high altitudes to the heat generated by electronic components during operation. This thermal stability ensures consistent performance of critical avionics systems throughout various flight phases, from takeoff to landing, and in the harsh conditions of space.

Vibration and Shock Resistance

Aerospace electronics are subjected to intense vibrations and shocks during launch, flight, and reentry. FR4 laminate's robust mechanical properties provide excellent resistance to these forces, preventing damage to delicate electronic components and maintaining the integrity of electrical connections. Its ability to absorb and dissipate vibrational energy helps protect sensitive equipment from mechanical stress, ensuring uninterrupted functionality of aerospace systems under demanding conditions.

Low Moisture Absorption

The low moisture absorption characteristic of FR4 laminate is crucial for maintaining the reliability of aerospace electronics. In high-altitude and space environments, where rapid pressure changes can occur, materials with high moisture absorption can lead to delamination and electrical failures. FR4's resistance to moisture ingress helps prevent these issues, ensuring the longevity and consistent performance of electronic systems in aerospace applications. This property is particularly valuable in satellite systems, where exposure to vacuum conditions could otherwise cause significant problems with less suitable materials.

FR4's Role in Lightweight, Rigid PCB Substrates for Aerospace

Weight Reduction in Aircraft Systems

FR4 epoxy laminate contributes significantly to weight reduction efforts in aerospace engineering. Its excellent strength-to-weight ratio allows for the creation of lightweight yet robust PCB substrates. This weight savings is crucial in aircraft design, where every gram matters in terms of fuel efficiency and payload capacity. By utilizing FR4 in avionics systems, aerospace engineers can minimize the overall weight of electronic components without compromising on performance or reliability, leading to more efficient and economical aircraft operations.

Structural Support for Complex Circuitry

The rigidity and dimensional stability of FR4 laminate make it an ideal substrate for complex aerospace electronic circuitry. It provides a stable platform for intricate multi-layer PCBs, which are common in advanced avionics systems. This structural support is essential for maintaining precise alignment of components and preventing warpage or flexing that could lead to connection failures. FR4's ability to withstand the mechanical stresses of aerospace environments while supporting dense, high-performance circuitry is a key factor in its widespread use in the industry.

Compatibility with Advanced Manufacturing Techniques

FR4 laminate's versatility extends to its compatibility with advanced PCB manufacturing techniques used in aerospace electronics. It can be easily machined, drilled, and shaped to accommodate complex designs and form factors required in modern avionics and satellite systems. FR4 is also well-suited for high-density interconnect (HDI) technologies, allowing for miniaturization of electronic systems without sacrificing functionality. This adaptability to cutting-edge manufacturing processes enables aerospace engineers to push the boundaries of electronic design, creating more compact, efficient, and powerful systems for aircraft and spacecraft alike.

Conclusion

FR4 epoxy laminate has proven to be an indispensable material in aerospace electronics, offering a unique combination of electrical, mechanical, and thermal properties that meet the demanding requirements of avionics and satellite systems. Its widespread use in PCB substrates for flight control systems, communication equipment, and navigation instruments underscores its importance in ensuring the reliability and safety of aerospace operations. As the aerospace industry continues to evolve, FR4 laminate remains a cornerstone material, enabling the development of lighter, more efficient, and increasingly sophisticated electronic systems that power the future of flight and space exploration.

Contact Us

For more information about our FR4 epoxy laminate products and their applications in aerospace electronics, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your aerospace electronic needs.

References

1. Aerospace Engineering and Materials Science Handbook, 5th Edition (2023)

2. Journal of Aerospace Electronic Systems, Vol. 58, Issue 4 (2022)

3. Advanced Materials for Avionics: Innovations and Applications (2021)

4. Satellite Technology: Principles and Applications, 3rd Edition (2022)

5. Proceedings of the International Conference on Aerospace Materials and Manufacturing (2023)

6. Handbook of Printed Circuit Board Materials for High-Reliability Applications (2021)