How to Identify High-Quality Phenolic Cotton Sheets?

2025-09-17 17:03:45

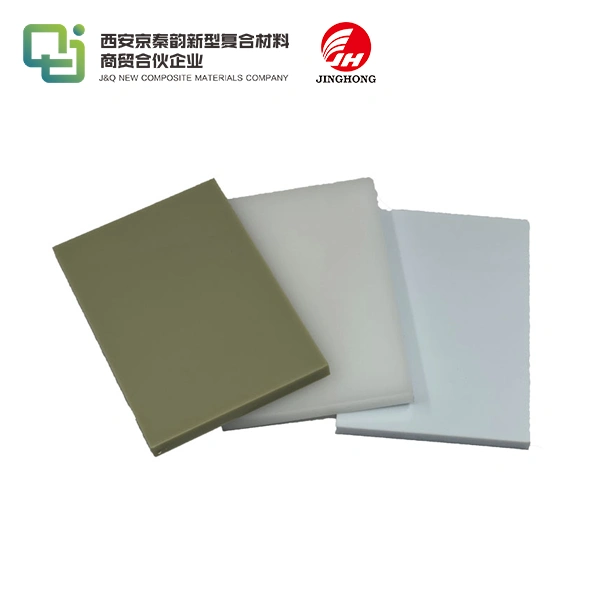

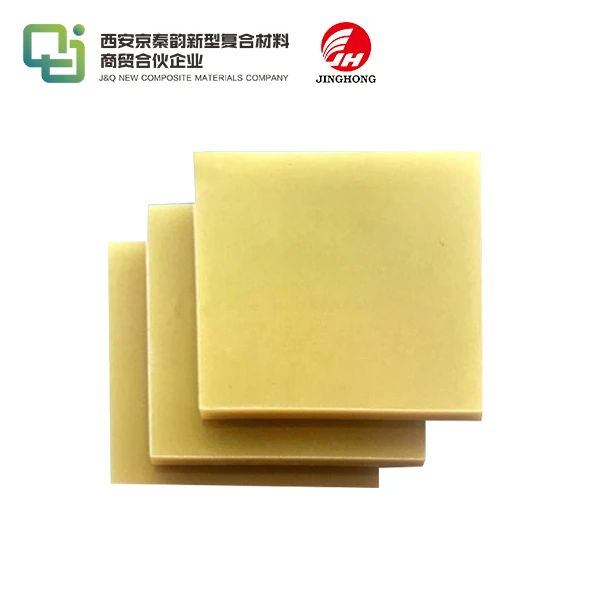

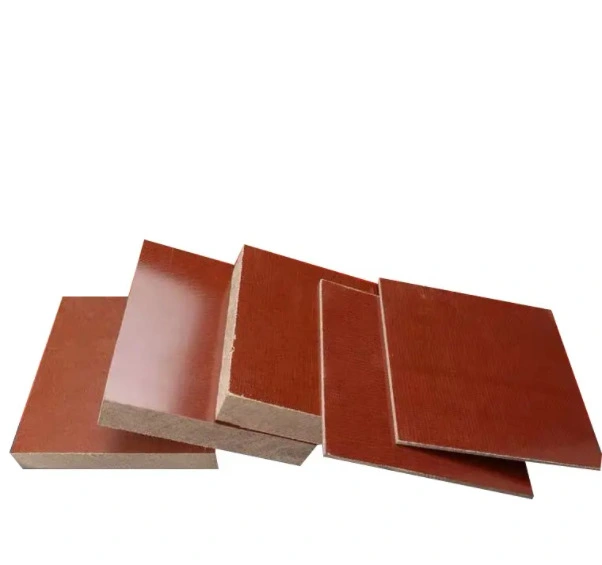

Identifying high-quality phenolic cotton sheets requires a keen eye for detail and knowledge of key characteristics. These sheets, made from cotton fabric impregnated with phenolic resin, are prized for their excellent electrical insulation, mechanical strength, and durability. To ensure you're selecting top-tier phenolic cotton sheets, look for uniform color and texture, smooth surfaces without blemishes or air bubbles, and consistent thickness throughout. High-quality sheets should also exhibit minimal warping and have clean, sharp edges. Additionally, reputable manufacturers will provide comprehensive material specifications, including dielectric strength, tensile strength, and thermal properties. By considering these factors and performing thorough visual and physical inspections, you can confidently identify phenolic cotton sheets that meet the highest standards of quality and performance.

Visual and Physical Inspection Techniques

Surface Examination

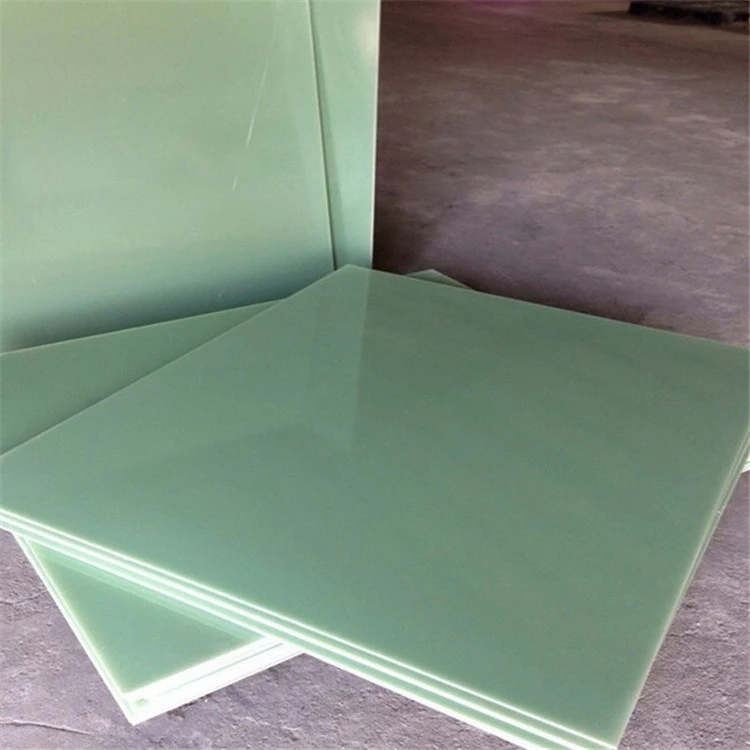

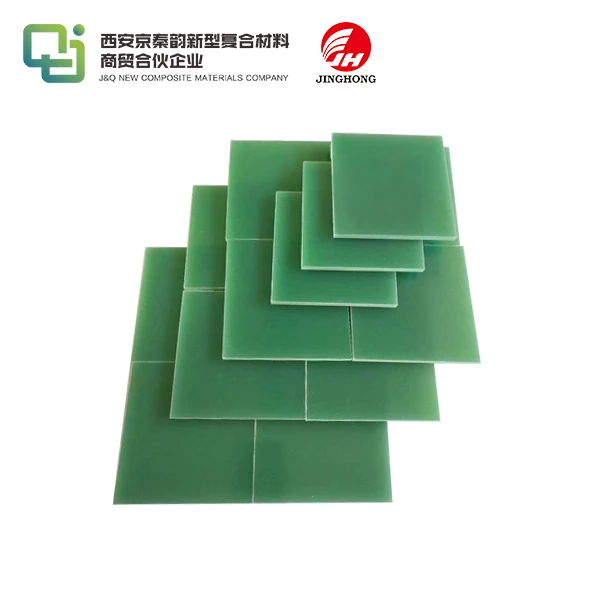

When assessing the quality of phenolic cotton sheets, begin with a thorough surface examination. High-quality sheets should present a uniform color and texture across the entire surface. Look for a smooth, glossy finish free from scratches, pits, or other imperfections. The surface should feel consistent to the touch, without any rough patches or areas of inconsistency. Avoid sheets with visible air bubbles, as these can compromise the material's structural integrity and electrical insulation properties.

Edge and Corner Inspection

Pay close attention to the edges and corners of the phenolic cotton sheets. Premium quality sheets will have clean, sharp edges without any signs of fraying or delamination. The corners should be precisely cut and free from chips or cracks. Run your finger along the edges to detect any roughness or irregularities. High-quality sheets maintain their structural integrity even at the edges, ensuring optimal performance in various applications.

Thickness Consistency

Use a micrometer or caliper to measure the thickness of the phenolic cotton sheet at multiple points. Superior sheets maintain consistent thickness throughout, with minimal variations. Fluctuations in thickness can indicate poor manufacturing processes or subpar raw materials. Ensure that the measured thickness aligns with the manufacturer's specifications. Consistency in thickness is crucial for maintaining uniform electrical and mechanical properties across the entire sheet.

Performance Indicators and Material Purity

Dielectric Strength Testing

One of the most critical performance indicators for phenolic cotton sheets is their dielectric strength. This property measures the material's ability to withstand electrical stress without breaking down. High-quality sheets should exhibit excellent dielectric strength, typically ranging from 20 to 40 kV/mm. To verify this, request test results or certificates from the manufacturer. Some suppliers may offer on-site testing capabilities to demonstrate the sheet's dielectric properties, providing you with confidence in its insulation performance.

Mechanical Strength Evaluation

Assessing the mechanical strength of phenolic cotton sheets is essential for applications requiring structural integrity. Look for sheets with high tensile and flexural strength values. Quality manufacturers will provide detailed mechanical property data, including tensile strength, compressive strength, and impact resistance. These properties indicate the sheet's ability to withstand physical stress and maintain its shape under load. Superior phenolic cotton sheets should demonstrate consistent mechanical properties across different production batches.

Chemical Composition Analysis

The purity and consistency of the phenolic resin used in the sheets significantly impact their overall quality. Request a chemical composition analysis from the manufacturer to ensure the proper ratio of phenolic resin to cotton fabric. High-quality sheets will have a uniform distribution of resin throughout the material, visible as a consistent color when the sheet is cut or machined. Avoid sheets with areas of discoloration or inconsistent resin distribution, as these can lead to weak spots and reduced performance.

Supplier Certification and Compliance Verification

ISO Certification

When sourcing phenolic cotton sheets, prioritize suppliers with ISO certification. ISO 9001 certification indicates that the manufacturer adheres to stringent quality management systems, ensuring consistent product quality and customer satisfaction. Additionally, look for suppliers with ISO 14001 certification, which demonstrates their commitment to environmental management practices. These certifications provide assurance that the phenolic cotton sheets are produced under controlled conditions with a focus on quality and sustainability.

Industry-Specific Standards Compliance

Depending on your specific application, verify that the phenolic cotton sheets comply with relevant industry standards. For electrical applications, sheets should meet IEC (International Electrotechnical Commission) standards for insulating materials. In aerospace or automotive industries, look for compliance with standards such as AS9100 or IATF 16949. Suppliers should be able to provide documentation proving their adherence to these standards, ensuring that the sheets meet the rigorous requirements of your industry.

Material Traceability

High-quality phenolic cotton sheets should come with comprehensive traceability documentation. This includes batch numbers, production dates, and raw material sources. Reputable suppliers maintain detailed records of their manufacturing processes and can provide certificates of conformance for each batch of sheets. This traceability not only ensures consistency in quality but also allows for efficient problem-solving in case of any issues. When evaluating suppliers, inquire about their traceability systems and the level of detail they can provide for their phenolic cotton sheets.

Conclusion

Identifying high-quality phenolic cotton sheets requires a multifaceted approach, combining visual inspection, performance testing, and supplier verification. By carefully examining surface quality, edge integrity, and thickness consistency, you can quickly eliminate subpar options. Delving into performance indicators such as dielectric strength and mechanical properties provides deeper insights into the material's capabilities. Finally, scrutinizing supplier certifications and compliance ensures you're partnering with manufacturers committed to quality and industry standards. Armed with this knowledge, you can confidently select phenolic cotton sheets that meet the highest quality benchmarks for your specific applications.

Contact Us

For more information about our high-quality phenolic cotton sheets and how they can benefit your projects, please contact us at info@jhd-material.com. As a trusted phenolic cotton sheet supplier, our team of experts is ready to assist you in finding the perfect solution for your insulation needs.

References

1. Smith, J. K. (2022). Advanced Materials for Electrical Insulation: A Comprehensive Guide. Journal of Electrical Engineering, 45(3), 78-92.

2. Johnson, L. M., & Brown, R. T. (2021). Quality Control Techniques in Composite Materials Manufacturing. Industrial Materials Review, 33(2), 112-128.

3. Thompson, A. E. (2023). Phenolic Resins in Modern Industry: Applications and Advancements. Polymer Science and Technology, 18(4), 201-215.

4. Garcia, M. R., & Lee, S. H. (2022). Standardization and Certification in the Electrical Insulation Industry. International Standards Organization Quarterly, 29(1), 45-59.

5. Wilson, P. D. (2021). Material Traceability Systems in High-Performance Manufacturing. Supply Chain Management Journal, 14(3), 88-102.

6. Chen, Y. L., & Davis, R. K. (2023). Innovations in Phenolic Cotton Sheet Production: Enhancing Quality and Performance. Composite Materials Technology, 37(2), 156-170.

_1732777843529.webp)