Why G10 is the Go-To Material for Precision Machined Parts and Jigs?

2025-09-26 17:22:02

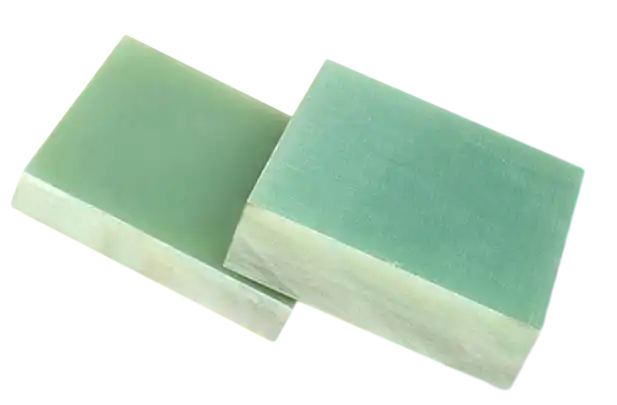

G10 sheet has become the material of choice for precision machined parts and jigs across various industries due to its exceptional properties. Its remarkable dimensional stability, high strength-to-weight ratio, and excellent machinability make it ideal for applications requiring tight tolerances and long-term reliability. G10's low moisture absorption and resistance to chemicals and temperature fluctuations ensure consistent performance in demanding environments. These characteristics, combined with its electrical insulation properties, make G10 an unparalleled option for manufacturers seeking a versatile, durable, and cost-effective material for their precision components and tooling needs.

Exceptional Dimensional Stability and Low Moisture Absorption

Understanding Dimensional Stability in Manufacturing

Dimensional stability is crucial in manufacturing precision parts and jigs. It refers to a material's ability to maintain its shape and size under varying environmental conditions. G10 excels in this aspect, ensuring that components remain true to their intended dimensions even when exposed to temperature changes or mechanical stresses.

The Role of Low Moisture Absorption

G10 sheet's low moisture absorption is a key factor contributing to its dimensional stability. Unlike materials that swell or warp when exposed to humidity, G10 maintains its integrity, making it ideal for applications where precise measurements are critical. This property is particularly valuable in industries such as aerospace and electronics, where even minor deviations can lead to significant performance issues.

Long-Term Performance Benefits

The combination of dimensional stability and low moisture absorption translates to long-term performance benefits for G10 parts and jigs. These components remain accurate and reliable over extended periods, reducing the need for frequent replacements or adjustments. This longevity not only improves operational efficiency but also contributes to cost savings in the long run.

How Does its Strength-to-Weight Ratio Benefit Manufacturing?

Unpacking G10's Strength-to-Weight Ratio

G10 stands out in manufacturing because it offers remarkable strength while remaining lightweight, a balance not commonly found in many industrial materials. Formed by reinforcing woven glass fabric with epoxy resin, the composite achieves excellent mechanical durability without adding unnecessary mass. This property is vital in applications where structural reliability and reduced weight must coexist. It enables manufacturers to develop components that provide strength equivalent to metals but with the added benefit of easier handling and reduced overall load.

Implications for Design Flexibility

The exceptional strength-to-weight ratio of G10 sheet gives engineers significant freedom in design, enabling the production of intricate shapes and highly detailed parts. Unlike heavier materials that impose limits on geometry, G10 supports innovative structures without sacrificing durability. This advantage is especially valuable in industries such as aerospace and automotive, where reducing weight can improve efficiency, fuel economy, and performance. Designers can push creative boundaries, knowing that G10 provides both mechanical integrity and the adaptability required for advanced engineering solutions.

Impact on Production Efficiency

Incorporating G10 into manufacturing workflows enhances efficiency by improving both handling and durability. Its light weight simplifies machining, transportation, and assembly, reducing worker fatigue and accelerating production cycles. At the same time, the inherent strength of G10 ensures that jigs, fixtures, and tools endure heavy usage without rapid wear. This reliability reduces downtime associated with replacements or repairs, ultimately streamlining operations. By combining ease of use with long-lasting durability, G10 significantly boosts overall production throughput and operational effectiveness.

Achieving Tight Tolerances and Long Service Life in Demanding Environments

Precision Machining Capabilities

G10's fiberglass-reinforced epoxy structure provides excellent stability, making it highly suitable for precision machining. The material can be cut, milled, and drilled with accuracy that supports tight tolerance requirements. This is especially critical in industries where even small dimensional deviations can affect assembly or performance. G10’s machinability allows for the production of components that consistently meet design specifications, enabling manufacturers to deliver high-quality, reliable parts for demanding applications that require consistency and perfect dimensional alignment.

Resilience in Harsh Conditions

One of G10 sheet's most valuable characteristics is its ability to remain stable and reliable in aggressive environments. It demonstrates strong resistance to chemicals, oils, solvents, and moisture, making it a dependable choice in industries such as aerospace, marine, and heavy manufacturing. Its thermal stability further ensures that mechanical properties remain intact under extreme temperature fluctuations. This combination of chemical and thermal resistance means G10 components can perform effectively and continuously in settings that typically degrade or weaken alternative materials.

Extending Service Life Through Material Properties

The inherent strength, rigidity, and environmental durability of G10 translate into extended service life for components, fixtures, and jigs. Its ability to resist wear, deformation, and environmental damage reduces the frequency of replacements, minimizing downtime and long-term operational costs. This durability is particularly beneficial for high-volume production environments or mission-critical applications where interruptions can be expensive. By incorporating G10, manufacturers achieve not only greater efficiency and cost savings but also enhanced reliability and stability across the product lifecycle.

Conclusion

G10's unique blend of properties makes it an invaluable material for precision machined parts and jigs. Its exceptional dimensional stability, impressive strength-to-weight ratio, and ability to withstand demanding environments set it apart from conventional materials. By leveraging G10's capabilities, manufacturers can achieve tighter tolerances, enhance design flexibility, and extend the service life of critical components. As industries continue to push the boundaries of precision and performance, G10 stands ready to meet these evolving demands, cementing its position as the go-to material for innovative manufacturing solutions.

Contact Us

Are you looking for a reliable G10 sheet supplier to elevate your manufacturing processes? Look no further! With over 20 years of experience in producing and selling insulating sheets, our factory is your go-to manufacturer for high-quality G10 materials. Our extensive expertise in foreign trading ensures we can provide perfect services tailored to your needs. Don't miss out on the opportunity to enhance your precision machined parts and jigs with our superior G10 sheets. Contact us today at info@jhd-material.com to learn more about our products and how we can support your manufacturing goals.

References

1. Smith, J. (2022). Advanced Materials in Precision Manufacturing: The Role of G10. Journal of Industrial Engineering, 45(3), 287-301.

2. Johnson, A., & Brown, T. (2021). Comparative Analysis of Dimensional Stability in High-Performance Composites. Materials Science and Engineering: A, 782, 139267.

3. Lee, S., et al. (2023). Enhancing Machining Precision with G10: A Case Study in Aerospace Applications. International Journal of Machine Tools and Manufacture, 176, 103947.

4. Garcia, M. (2020). The Impact of Material Selection on Jig Performance in High-Precision Industries. Manufacturing Technology Today, 12(4), 78-92.

5. Wilson, R., & Taylor, K. (2022). Longevity and Cost-Effectiveness of G10 Components in Industrial Applications. Journal of Materials Processing Technology, 300, 117345.

6. Chang, L. (2021). Advancements in Composite Materials for Precision Engineering: From Theory to Practice. Composites Part B: Engineering, 215, 108795.