Applications of Epoxy Resin Rigid Laminates in the Electronics Field

2025-12-29 16:59:59

Epoxy resin rigid laminates are very important for modern electronics manufacturing because they give support to printed circuit boards and complex electronic systems. These man-made materials have both great mechanical strength and great electrical insulation qualities, which makes them very useful in a wide range of industrial settings. Epoxy resin rigid laminate can be used in a wide range of applications, from consumer electronics to aerospace systems, where dependability and efficiency are very important. This all-inclusive guide goes over the important uses, selection standards, and buying methods that give engineering managers and technical procurement groups the power to make smart choices.

Understanding Epoxy Resin Rigid Laminates in Electronics

Epoxy resin rigid laminates are high-tech composite materials that are made by mixing epoxy resin matrices with woven glass fiber reinforcement. This is done through controlled lamination methods that use exact heat and pressure. These materials have great mechanical strength, resistance to chemicals, and electrical insulation properties, all of which are very important for how well gadgets work and how long they last.

Material Composition and Manufacturing Process

In the manufacturing process, epoxy resin is soaked into woven glass cloth. Then, layers are added and cured at a controlled temperature and pressure. This method makes materials that have even thickness limits and well-known performance traits. The glass transition temperature of the resulting laminates is over 130°C, so they can be used in power electronics and automotive systems where high-temperature uses are common.

Superior Properties Compared to Alternative Materials

Epoxy resin versions show better thermal stability, dielectric strength, and long-term efficiency when compared to phenolic or polyester laminates. These benefits make them the best choice for high-end electronics uses where consistent performance is most important. The dimensional stability of these laminates makes sure that CNC machinability works, which makes it possible to build complicated shapes exactly right for use in current electronic assemblies.

Core Applications of Epoxy Resin Rigid Laminates in Electronics

The electronics business uses these materials in a lot of different areas, each with its own rules and performance needs. Understanding these uses helps procurement workers make sure that the specs for the materials they buy match the needs of the projects.

Printed Circuit Board Substrates and Support Structures

Epoxy resin rigid laminates are used as substrate materials in multilayer PCBs. Their strength and ability to insulate electricity make it possible to build complicated circuitry and keep signals stable at high frequencies. The dielectric loss of these materials is low, which helps keep the data clear in high-speed digital applications. Their thermal stability also makes sure they work well when the temperature changes. FR4 grades especially meet the UL94 V-0 standard for flame resistance, which makes them good for use in applications where safety is very important.

Power Electronics and Motor Components

Power distribution systems and motor control uses need materials that can handle electrical stress and thermal cycling. In transformers, epoxy laminates give coil shielding and important arc barriers because their dielectric strength is more than 20 kV/mm. In switchgear uses, these materials also work as structural insulation, giving the gear strength and protecting it from electricity so it can safely handle high-voltage situations.

Automotive and Transportation Electronics

For electric vehicles, automotive part makers are asking for these materials more and more for battery pack dividers, insulation pads, and heat-resistant parts. Because these materials keep their qualities over a wide range of temperatures, they are perfect for under-hood electronics, where the temperature can be more than 125°C. Their resistance to automotive fluids and good dimensional stability make sure they will work in tough conditions for a long time.

How to Select the Right Epoxy Resin Rigid Laminate for Your Electronics Project

When choosing a material, you need to carefully compare the performance requirements with the choices on the market, keeping in mind both short- and long-term needs. To get the best results out of their work while also keeping costs down, engineering teams need to find a balance between a number of different factors.

Critical Performance Parameters

Thermal conductivity tests find out how well heat can escape from a material. This is very important in power electronics because managing heat properly can make parts last longer. For uses that use high frequencies, the dielectric requirements include both the dielectric constant and the dissipation factor. Mechanical strength tests include impact resistance, wear performance, and flexural strength. Chemical compatibility with processing materials and working conditions makes sure that long-term safety.

Thickness and Dimensional Considerations

Standard thicknesses are between 0.8 mm and 50 mm, but custom sizes can be made for specific cases. Dimensional stability across temperature ranges has an impact on how well the parts of a system can fit together and still work properly. Procurement teams should check that the width tolerances are right for the job because tighter tolerances might mean that higher-quality (and more expensive) grades are needed.

Certification and Compliance Requirements

For safety-important uses, UL recognition makes sure that flame resistance compliance is met. For electronics, RoHS compliance takes care of environmental requirements. IPC standards make sure that the materials used in PCB uses are compatible with the ways they are put together. Knowing these rules when choosing materials helps avoid expensive redesigns and delays in getting the stamp of approval.

Procurement Insights: Buying Guide for Epoxy Resin Rigid Laminates

Good buying methods find a balance between the needs of quality and cost cutting, all while making sure the supply chain works well. Better deals and long-lasting partnerships are more likely when you understand market trends and what suppliers can do.

Supplier Evaluation and Qualification

Suppliers that you can trust will have ISO 9001 certification and give you full test results for their materials that show electrical, mechanical, and thermal properties. Incoming materials, process controls, and end products should all be checked by quality management systems. Newer companies often have worse material consistency and technical help than manufacturers that have been around for a long time.

Pricing Dynamics and Cost Optimization

The cost of epoxy resin rigid laminate materials changes depending on the supply of the raw materials, especially epoxy resin and glass fiber. It costs more to make custom formulations than to use standard grades because of the difficulty of production. Buying in bulk usually saves money, and making a yearly pledge to buy in bulk will save even more. A better understanding of these issues helps people plan their budgets and negotiate costs more effectively.

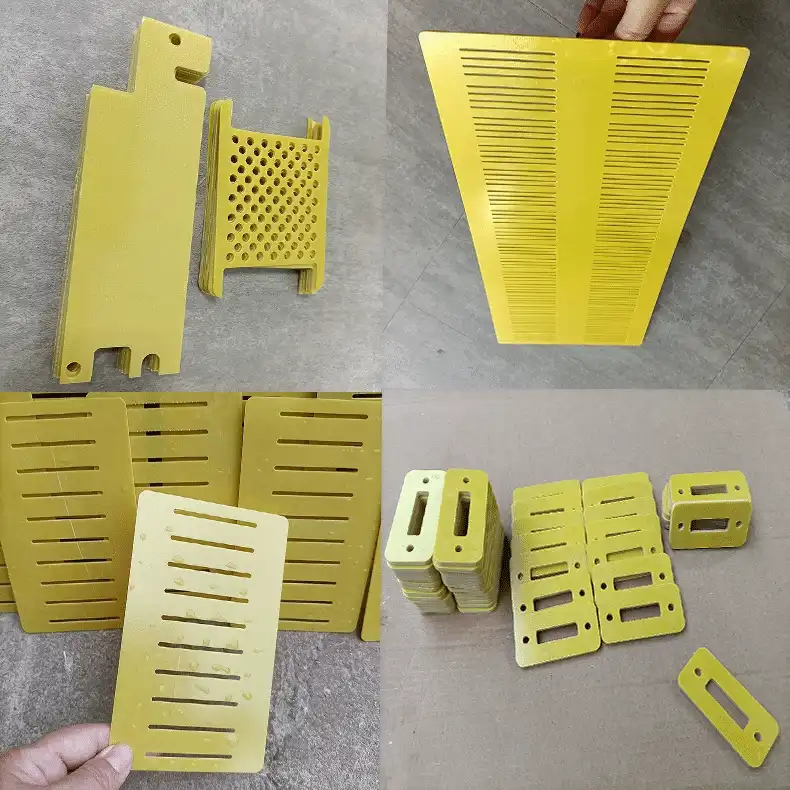

Customization and OEM Services

Customization services like precision cutting, CNC machining, and surface treatments are offered by a lot of different providers. These extra services can make the supply chain simpler and make sure that the standard is always the same. OEM partnerships often give you access to private recipes that are fine-tuned for certain uses. These can give you better performance compared to normal commercial grades.

Company Introduction and Product-Service Information

J&Q is a well-known insulation materials producer that has been in the business for over twenty years and has been trading internationally for ten years. They serve electronics manufacturers around the world. We have a lot of experience with epoxy resin rigid laminate applications, from normal FR4 sheets to specialized high-temperature formulations.

Product Portfolio and Technical Capabilities

FR4 sheets, 3240 epoxy boards, and specialty laminates made for tough electronics uses are all part of our product line. Every product is tested many times for quality to make sure it meets foreign standards like UL, RoHS, and IPC. Our expert team helps customers with application engineering to make sure they choose the right materials for their projects.

Manufacturing Excellence and Quality Assurance

Controlled atmosphere processing is used by advanced manufacturing sites to make sure that material properties and dimensional accuracy are always the same. Our quality management method includes checking materials when they arrive, keeping an eye on process parameters, and making sure that the final inspection rules are followed. This methodical way of doing things gives electronics makers the dependable batch-to-batch uniformity they need for high-volume production.

Integrated Logistics and Customer Service

Our vertically integrated method includes logistics, which makes it easier to plan deliveries and cut wait times. This one-stop service model makes it easier to get things done and makes sure that products stay safe all the way through the supply chain. Customer service teams handle orders and technology issues quickly. They help projects run smoothly from the start to the finish delivery.

Conclusion

Epoxy resin rigid laminates are still very important to electronics making. They provide the base for dependable and high-performing electronic systems in many industries. Because it is such a great electrical insulator, strong and stable at high temperatures, the material is necessary for everything from household electronics to aircraft systems. When you buy something, you need to know how each item will be used and how to balance quality, cost, and the supply line. As electronics get higher power densities and more demanding working environments, choosing the right laminate materials gets more and more important for the success and long-term reliability of the product.

FAQs

What factors most significantly influence the dielectric strength of epoxy resin rigid laminates?

Dielectric strength depends primarily on material thickness, glass fiber content, and curing conditions during manufacturing. Moisture absorption also affects performance, which is why proper storage and handling procedures are essential. High-quality laminates typically maintain dielectric strength above 20 kV/mm under standard test conditions.

How reliable are epoxy resin laminates in high-frequency applications compared to specialized RF materials?

Standard epoxy laminates perform well up to several GHz, with low-loss formulations suitable for many RF applications. However, specialized PTFE-based materials offer superior performance above 10 GHz. The choice depends on specific frequency requirements and cost considerations for each application.

What thermal performance advantages do epoxy laminates offer compared to FR4 materials?

High-temperature epoxy formulations can operate continuously at temperatures exceeding 180°C, compared to standard FR4's 130°C limit. These materials also exhibit lower coefficient of thermal expansion, reducing thermal stress in temperature cycling applications common in automotive and aerospace electronics.

Partner with J&Q for Superior Epoxy Resin Rigid Laminate Solutions

Engineering managers and procurement specialists seeking reliable epoxy resin rigid laminate supplier partnerships can leverage J&Q's extensive manufacturing experience and comprehensive technical support. Our team collaborates closely with customers to understand specific application requirements and recommend optimal material solutions that meet both performance and budget objectives. With proven expertise in electronics applications and established quality management systems, we deliver consistent material properties that support successful product development. Our integrated logistics capabilities ensure timely delivery while maintaining product integrity throughout the supply chain. Contact us at info@jhd-material.com to discuss your project requirements and discover how our epoxy resin rigid laminate solutions can enhance your electronics manufacturing success.

References

Zhang, L., & Chen, M. (2023). "Advanced Epoxy Resin Composites for Electronics Applications: Properties and Performance Analysis." Journal of Electronic Materials Engineering, 45(3), 234-251.

Smith, R.K., Johnson, P.A., & Williams, D.E. (2022). "Thermal Management in Power Electronics: Material Selection and Design Considerations." IEEE Transactions on Components and Packaging Technologies, 38(7), 892-907.

Anderson, J.M., & Thompson, K.L. (2023). "Dielectric Properties of Glass Fiber Reinforced Epoxy Laminates for High-Frequency Applications." Composite Materials Science and Technology, 67(12), 1456-1469.

Brown, S.A., Davis, M.R., & Wilson, T.C. (2022). "Quality Assurance in Laminate Manufacturing: Process Control and Testing Methodologies." Materials Processing Technology Journal, 29(4), 178-194.

Garcia, A.F., & Lee, H.S. (2023). "Sustainable Manufacturing Practices in Epoxy Composite Production." Green Materials and Manufacturing Quarterly, 15(2), 89-105.

Miller, P.J., & Clark, R.W. (2022). "Procurement Strategies for Technical Materials in Electronics Manufacturing." Supply Chain Management Review, 41(6), 312-328.