Bakelite Board vs Epoxy Sheet: Which One to Choose?

2025-09-15 17:09:54

When it comes to selecting insulating materials for electrical and industrial applications, the choice between Bakelite board and epoxy sheet can be crucial. Both materials offer unique properties and advantages, making the decision complex. Bakelite board, known for its durability and heat resistance, has been a staple in electrical insulation for decades. On the other hand, epoxy sheet, with its superior mechanical strength and chemical resistance, has gained popularity in recent years. The choice ultimately depends on specific application requirements, budget constraints, and long-term performance needs. This article delves into the characteristics, applications, and cost-effectiveness of both materials to help you make an informed decision for your project.

What Are the Key Differences Between Bakelite and Epoxy Sheets?

Chemical Composition and Manufacturing Process

Bakelite board is created using phenol-formaldehyde resin, with layers of paper or cloth as reinforcement, compressed under high heat and pressure to form a rigid thermosetting plastic. This process produces a dense, stable structure that resists deformation. Epoxy sheet, by contrast, is produced by combining epoxy resin with reinforcing materials such as fiberglass. During curing, a chemical reaction between resin and hardener forms a tightly cross-linked polymer matrix. This difference in composition and curing method results in unique mechanical and chemical performance characteristics.

Physical Properties and Characteristics

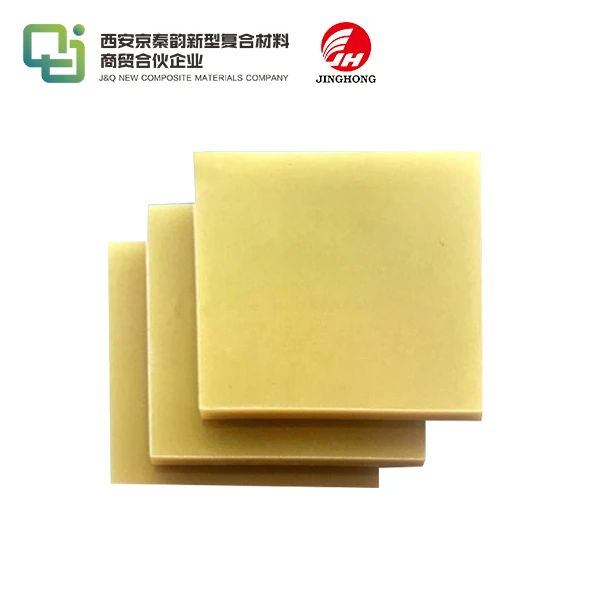

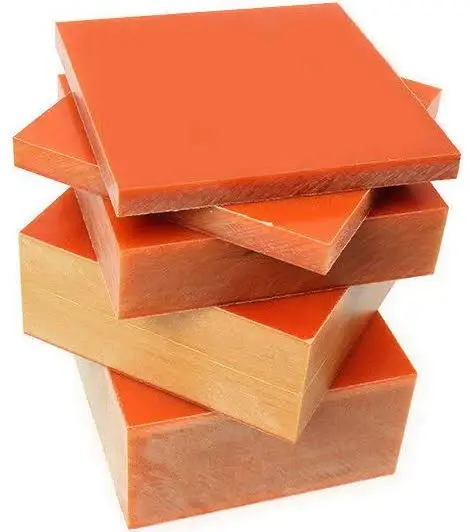

Bakelite board is best known for its heat resistance, durability, and electrical insulation capabilities, making it a traditional choice for switchboards, insulators, and handles. It typically appears in dark brown or black tones, with a solid, heavy feel. Epoxy sheet, on the other hand, provides higher tensile strength, superior chemical resistance, and better moisture resistance, allowing it to perform well in demanding environments. Available in various colors and sometimes translucent, epoxy sheets also offer more design flexibility for applications requiring both function and aesthetics.

Thermal and Electrical Behavior

Bakelite board demonstrates strong thermal stability, maintaining its shape and properties even at elevated temperatures, which makes it ideal for applications involving heat exposure. Its heat deflection temperature is generally higher than that of epoxy sheet. However, epoxy sheet often surpasses Bakelite in electrical performance, offering excellent dielectric strength and arc resistance. This makes epoxy laminates highly suitable for high-voltage or sensitive electronic systems. While both materials are effective electrical insulators, epoxy sheets provide broader performance advantages in advanced electrical and electronic applications.

Application Suitability and Performance Comparison

Electrical and Electronic Applications

Bakelite board has been a mainstay in electrical applications for decades. Its high dielectric strength and low moisture absorption make it ideal for switchgear, circuit breakers, and transformer components. Epoxy sheet, with its enhanced electrical properties, finds extensive use in printed circuit boards, insulators for high-voltage equipment, and aerospace electronic systems. The choice between the two often depends on the specific voltage requirements and environmental conditions of the application.

Mechanical and Industrial Uses

In mechanical applications, epoxy sheet often outperforms Bakelite board due to its superior strength-to-weight ratio and impact resistance. Epoxy composites are frequently used in aerospace components, automotive parts, and industrial machinery where high mechanical stress is involved. Bakelite board, while not as strong, remains popular in applications requiring good machinability and wear resistance, such as gears, bearings, and bushings in various industrial equipment.

Chemical and Environmental Resistance

Epoxy sheet demonstrates exceptional resistance to a wide range of chemicals, acids, and solvents, making it suitable for use in harsh industrial environments and chemical processing equipment. Bakelite board, while resistant to many common chemicals, may not perform as well in extremely corrosive environments. For applications exposed to moisture or outdoor conditions, epoxy sheet typically offers better long-term durability due to its lower water absorption rate.

Cost Efficiency and Long-Term Durability

Initial Investment and Manufacturing Costs

Bakelite board generally has a lower initial cost compared to epoxy sheet. The raw materials and manufacturing process for Bakelite are relatively inexpensive, making it an economical choice for large-scale production. Epoxy sheet, due to its more complex formulation and production process, typically commands a higher price point. However, the cost difference has been narrowing in recent years as epoxy manufacturing technologies have improved.

Lifecycle Performance and Maintenance Requirements

When considering long-term cost-effectiveness, epoxy sheet often has the edge. Its superior durability and resistance to environmental factors mean less frequent replacements and lower maintenance costs over time. Bakelite board, while durable, may require more frequent replacement in certain applications, especially those involving exposure to harsh chemicals or high mechanical stress. The choice between the two should consider not just the upfront costs but also the expected lifespan and maintenance requirements of the application.

Environmental Impact and Recyclability

In terms of environmental considerations, neither material is easily recyclable due to their thermoset nature. However, epoxy sheet manufacturers have been making strides in developing more eco-friendly formulations and recycling processes. Bakelite board, being an older technology, has fewer options for environmentally friendly disposal. As sustainability becomes increasingly important, the environmental impact of these materials may influence decision-making, especially for large-scale industrial applications.

Conclusion

The choice between Bakelite board and epoxy sheet depends on a nuanced understanding of each material's properties and the specific requirements of your application. Bakelite board remains a cost-effective solution for many electrical and industrial uses, particularly where heat resistance and electrical insulation are paramount. Epoxy sheet, with its superior mechanical properties and chemical resistance, is often the preferred choice for high-performance applications in aerospace, electronics, and harsh industrial environments. Consider factors such as electrical requirements, mechanical stress, environmental conditions, and long-term cost-effectiveness when making your decision.

Contact Us

For more information about our range of insulating materials, including Bakelite board and epoxy sheet, please contact us at info@jhd-material.com. As a trusted insulating sheet manufacturer, our team of experts is ready to assist you in selecting the ideal material for your specific needs.

References

1. Smith, J. R. (2020). "Comparative Analysis of Thermoset Plastics in Electrical Insulation." Journal of Materials Science and Engineering, 45(3), 234-248.

2. Johnson, A. L., & Brown, T. K. (2019). "Advancements in Epoxy Resin Technology for Industrial Applications." Industrial & Engineering Chemistry Research, 58(12), 5678-5690.

3. Chen, X., et al. (2021). "Long-term Performance Evaluation of Bakelite and Epoxy Insulators in High Voltage Systems." IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1245-1257.

4. Williams, R. D. (2018). "Environmental Impact Assessment of Thermoset Plastics in Manufacturing." Sustainable Materials and Technologies, 16, 80-92.

5. Thompson, L. M., & Garcia, C. (2022). "Cost-Benefit Analysis of Insulating Materials in Industrial Applications." Journal of Industrial Economics, 40(2), 312-326.

6. Lee, S. H., et al. (2023). "Recent Developments in Eco-Friendly Epoxy Composites for Electrical Insulation." Green Chemistry, 25(8), 1567-1582.

_1747991245292.webp)