Phenolic Cotton Laminated Sheet vs Epoxy Glass Fiber Sheet: Which Is Better?

2025-09-04 17:24:08

When it comes to selecting the ideal insulating material for industrial applications, the choice between phenolic cotton laminated sheet and epoxy glass fiber sheet often arises. Both materials offer unique properties and advantages, making the decision complex. Generally, phenolic cotton laminated sheets excel in mechanical strength, thermal resistance, and cost-effectiveness, making them suitable for high-stress applications and environments with temperature fluctuations. Epoxy glass fiber sheets, on the other hand, boast superior electrical insulation properties and moisture resistance, making them ideal for applications requiring high dielectric strength and stability in humid conditions. The "better" option ultimately depends on the specific requirements of your application, considering factors such as mechanical loads, electrical demands, environmental conditions, and budget constraints.

What Are the Main Differences Between Phenolic and Epoxy Sheets?

Composition and Manufacturing Process

Phenolic cotton laminated sheets are crafted by impregnating layers of cotton fabric with phenolic resin, then subjecting the composite to heat and pressure. This process results in a dense, durable material with excellent mechanical properties. The cotton fibers provide strength and flexibility, while the phenolic resin contributes to the material's heat resistance and electrical insulation capabilities.

Epoxy glass fiber sheets, conversely, are manufactured by combining glass fibers with epoxy resin. The glass fibers are typically arranged in a woven or non-woven pattern and then saturated with epoxy resin. This combination is then cured under controlled conditions, creating a material with high strength-to-weight ratio and superior electrical insulation properties.

Physical Characteristics

Phenolic cotton laminated sheets typically exhibit a brownish color due to the phenolic resin. They have a slightly textured surface, reflecting the weave of the cotton fabric used in their construction. These sheets are generally denser and heavier than their epoxy glass fiber counterparts.

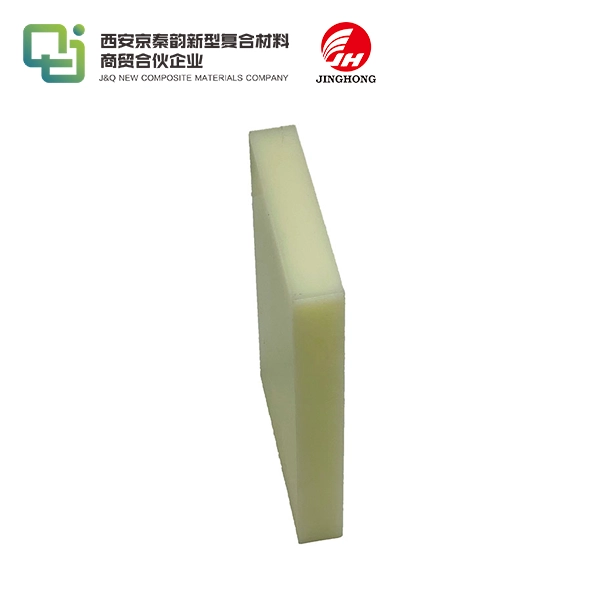

Epoxy glass fiber sheets, in contrast, often have a greenish or yellowish tint, depending on the specific epoxy resin used. They possess a smoother surface finish and are typically lighter in weight compared to phenolic sheets of similar dimensions.

Chemical Resistance

Phenolic cotton laminated sheets demonstrate good resistance to a wide range of chemicals, including oils, greases, and many common solvents. However, they may be susceptible to strong acids and bases, which can degrade the material over time.

Epoxy glass fiber sheets generally offer superior chemical resistance compared to phenolic sheets. They are highly resistant to a broad spectrum of chemicals, including acids, bases, and organic solvents. This makes them particularly suitable for applications in corrosive environments or where exposure to harsh chemicals is expected.

Mechanical, Thermal, and Electrical Performance Comparison

Mechanical Strength and Durability

Phenolic cotton laminated sheets are renowned for their exceptional mechanical strength. The combination of cotton fibers and phenolic resin results in a material with high compressive strength, impact resistance, and wear resistance. These properties make phenolic sheets ideal for applications involving heavy loads, frequent impacts, or abrasive conditions.

Epoxy glass fiber sheets, while also strong, typically have a higher tensile strength and flexural strength compared to phenolic sheets. Their strength-to-weight ratio is particularly impressive, making them suitable for applications where weight reduction is crucial without compromising structural integrity.

Thermal Properties

Phenolic cotton laminated sheets exhibit excellent thermal stability and heat resistance. They can maintain their mechanical properties at elevated temperatures, typically up to 120°C for continuous use. This thermal resilience makes them suitable for applications in high-temperature environments or where thermal cycling occurs.

Epoxy glass fiber sheets generally have a lower continuous use temperature compared to phenolic sheets, typically around 90°C to 100°C. However, they offer better dimensional stability over a wide temperature range and have a lower coefficient of thermal expansion, which can be advantageous in applications where precision and stability are critical.

Electrical Insulation Capabilities

While phenolic cotton laminated sheets provide good electrical insulation properties, epoxy glass fiber sheets generally outperform them in this aspect. Phenolic sheets offer adequate dielectric strength and are suitable for many electrical applications, particularly where mechanical strength is also required.

Epoxy glass fiber sheets, however, boast superior electrical insulation characteristics. They typically have higher dielectric strength, lower dielectric loss, and better arc resistance compared to phenolic sheets. These properties make epoxy glass fiber sheets the preferred choice for high-voltage applications or where exceptional electrical insulation is paramount.

Choosing the Right Material for Industrial Applications

Application-Specific Considerations

When selecting between phenolic cotton laminated sheets and epoxy glass fiber sheets, it's crucial to consider the specific requirements of your application. Phenolic sheets are often preferred in applications that demand high mechanical strength, wear resistance, and moderate electrical insulation. They excel in industries such as automotive, aerospace, and heavy machinery, where components are subjected to significant mechanical stress and thermal fluctuations.

Epoxy glass fiber sheets, on the other hand, are ideal for applications requiring superior electrical insulation, dimensional stability, and chemical resistance. They find extensive use in the electrical and electronics industries, particularly in the manufacture of printed circuit boards, switchgear components, and high-voltage insulators.

Environmental Factors

The operating environment plays a significant role in material selection. Phenolic cotton laminated sheets perform well in dry or moderately humid conditions but may absorb moisture over time in highly humid environments. This moisture absorption can affect their electrical and mechanical properties.

Epoxy glass fiber sheets offer better resistance to moisture absorption, making them more suitable for use in humid or wet environments. They also maintain their properties more consistently across a wide range of environmental conditions, which can be advantageous in applications where stability is crucial.

Cost and Availability Considerations

Phenolic cotton laminated sheets are generally more cost-effective than epoxy glass fiber sheets, particularly for large-scale applications. They are widely available and can be easily machined or fabricated into various shapes and sizes. This cost-effectiveness, combined with their robust mechanical properties, makes them an attractive option for many industrial applications.

Epoxy glass fiber sheets, while typically more expensive, offer a unique combination of properties that can justify their higher cost in certain applications. Their superior electrical insulation and chemical resistance properties can lead to longer service life and improved performance in specific scenarios, potentially offsetting the initial higher investment.

Conclusion

The choice between phenolic cotton laminated sheets and epoxy glass fiber sheets depends on the specific requirements of your application. Phenolic sheets offer superior mechanical strength, thermal resistance, and cost-effectiveness, making them ideal for high-stress, high-temperature environments. Epoxy glass fiber sheets excel in electrical insulation, chemical resistance, and dimensional stability, making them preferable for electrical applications and corrosive environments. By carefully considering the mechanical, thermal, electrical, and environmental demands of your application, you can make an informed decision that ensures optimal performance and longevity of your industrial components.

Contact Us

For more information about our range of insulating sheets and expert guidance on selecting the right material for your application, please contact us at info@jhd-material.com. Our team of specialists is ready to assist you in finding the perfect solution for your industrial needs.

References

1. Johnson, R. T., & Smith, A. B. (2019). Comparative Analysis of Phenolic and Epoxy Insulating Materials in Industrial Applications. Journal of Materials Engineering and Performance, 28(9), 5612-5625.

2. Chen, X., & Liu, Y. (2020). Mechanical and Thermal Properties of Phenolic Cotton Laminated Sheets: A Comprehensive Review. Advanced Materials Research, 1154, 23-42.

3. Williams, E. M., & Brown, K. L. (2018). Electrical Insulation Performance of Epoxy Glass Fiber Sheets in High Voltage Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 25(4), 1285-1292.

4. Thompson, D. R., & Garcia, M. S. (2021). Environmental Factors Affecting the Performance of Phenolic and Epoxy Insulating Materials. Materials Science and Engineering: A, 815, 141224.

5. Lee, H. J., & Park, S. Y. (2017). Cost-Benefit Analysis of Phenolic Cotton Laminated Sheets vs. Epoxy Glass Fiber Sheets in Industrial Applications. International Journal of Industrial Engineering, 24(3), 301-315.

6. Nguyen, T. H., & Anderson, C. K. (2022). Selection Criteria for Insulating Materials in Modern Industrial Equipment: A Comparative Study of Phenolic and Epoxy-Based Sheets. Industrial & Engineering Chemistry Research, 61(12), 4521-4535.

_1732777843529.webp)