Understanding the Specifications and Uses of 3240 Laminate Sheets

2025-08-29 17:10:26

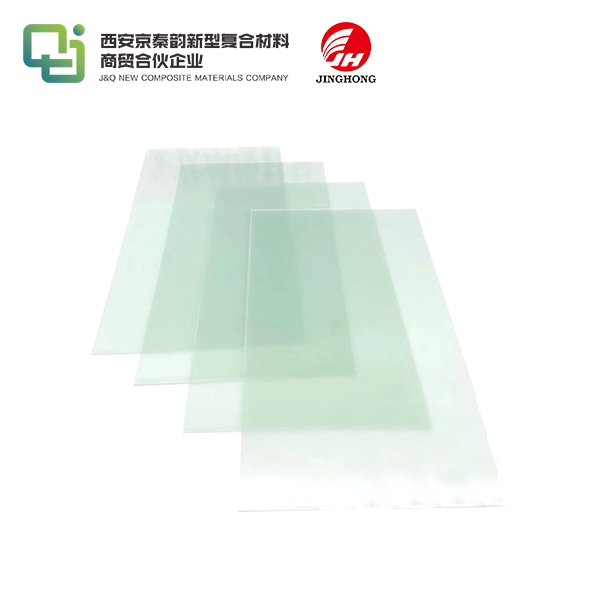

3240 laminate sheets are versatile insulating materials widely used in various industrial applications. These high-performance sheets offer a unique combination of mechanical strength, thermal resistance, and excellent electrical insulation properties. Manufactured through a meticulous process of layering epoxy resin and glass fabric, 3240 laminate sheets exhibit superior dimensional stability and resilience under diverse environmental conditions. Their distinctive green color and smooth surface finish make them easily recognizable in industrial settings. Understanding the specifications and applications of 3240 laminate sheets is crucial for engineers, manufacturers, and procurement specialists seeking reliable insulation solutions for their projects.

What Are the Standard Specifications of 3240 Laminate Sheets?

Dimensional Characteristics

3240 laminate sheets are available in a range of standard dimensions to suit various industrial needs. Typical sheet sizes include 1000mm x 2000mm, 1220mm x 2440mm, and custom sizes upon request. Thickness options generally range from 0.5mm to 50mm, allowing for flexibility in application. The sheets maintain tight thickness tolerances, usually within ±10% of the nominal thickness, ensuring consistency across production batches.

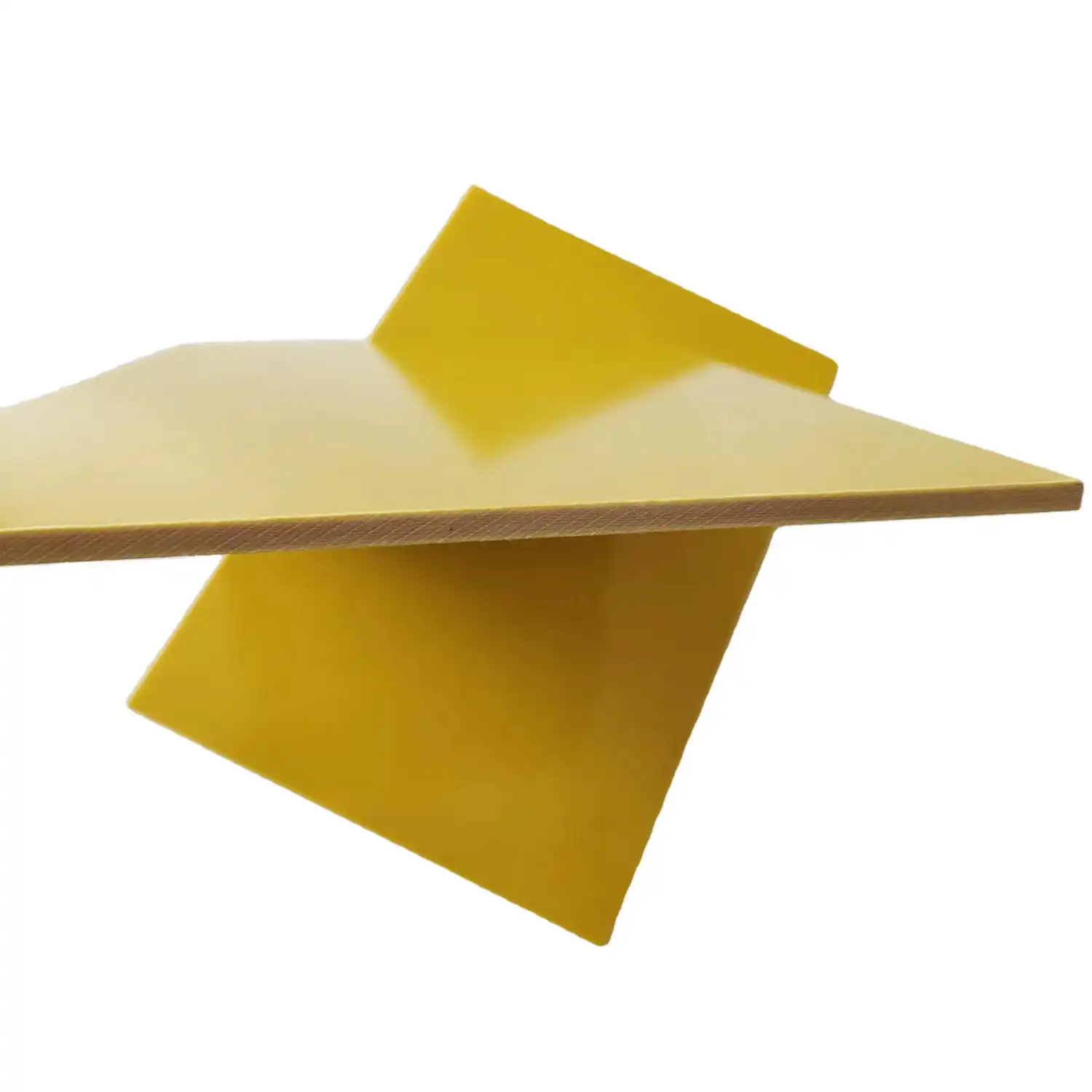

Material Composition

The core composition of 3240 laminate sheets consists of high-quality epoxy resin reinforced with woven glass fabric. This combination results in a material with a glass content typically ranging from 60% to 70% by weight. The epoxy resin used is specifically formulated to provide excellent adhesion to the glass fabric, creating a cohesive and durable composite structure.

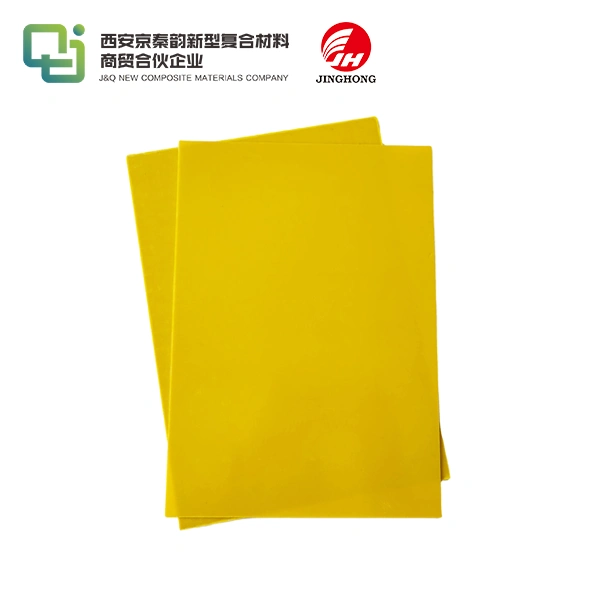

Surface Finish and Color

3240 laminate sheets are characterized by their smooth, glossy surface finish on both sides. This finish not only enhances the aesthetic appeal but also contributes to the material's insulation properties and resistance to environmental factors. The sheets exhibit a distinctive green color, which is consistent throughout the material, aiding in easy identification and quality control processes.

Mechanical, Thermal, and Electrical Properties of 3240 Sheets

Mechanical Strength Characteristics

3240 laminate sheets boast impressive mechanical properties, making them suitable for applications requiring high strength and rigidity. The flexural strength of these sheets typically ranges from 380 to 450 MPa, demonstrating their ability to withstand bending forces without failure. Compressive strength values often exceed 300 MPa, indicating excellent resistance to crushing or deformation under load. The material also exhibits a high tensile strength, usually between 300 and 350 MPa, which contributes to its overall durability and resistance to tearing or stretching.

Thermal Performance Metrics

The thermal properties of 3240 laminate sheets make them suitable for applications involving elevated temperatures. These sheets maintain their structural integrity and insulation properties at continuous operating temperatures up to 130°C, with short-term exposure capabilities reaching 180°C. The thermal conductivity of 3240 laminates is relatively low, typically around 0.3 W/m·K, which contributes to their effectiveness as thermal insulators. Additionally, the material demonstrates a low coefficient of thermal expansion, usually in the range of 10-20 x 10^-6 /°C, ensuring dimensional stability across a wide temperature range.

Electrical Insulation Capabilities

One of the most notable features of 3240 laminate sheets is their exceptional electrical insulation properties. The dielectric strength of these sheets often exceeds 20 kV/mm, providing robust protection against electrical breakdown. The volume resistivity is typically greater than 10^14 ohm·cm, indicating excellent resistance to current flow through the material. Surface resistivity values are equally impressive, usually above 10^13 ohms, which helps prevent surface tracking and electrical leakage. These electrical properties make 3240 laminates an ideal choice for applications in high-voltage environments and sensitive electronic equipment.

Common Applications of 3240 Laminate Sheets in Industry

Electrical and Electronics Sector

In the electrical and electronics industry, 3240 laminate sheets find extensive use due to their superior insulation properties. They are commonly employed in the production of switchgear components, such as busbar supports and phase barriers. The material's high dielectric strength makes it ideal for insulating high-voltage equipment, including transformers and circuit breakers. Electronics manufacturers also utilize 3240 laminates for printed circuit board substrates in applications requiring high thermal stability and excellent electrical insulation.

Automotive and Transportation

The automotive sector leverages the mechanical and thermal properties of 3240 laminate sheets in various applications. These materials are used in the fabrication of insulating components for electric vehicle battery systems, helping to maintain thermal stability and electrical safety. In conventional vehicles, 3240 laminates find application in underhood insulation, where their heat resistance and dimensional stability are crucial. The transportation industry also utilizes these sheets in the construction of composite panels for trains and buses, taking advantage of their lightweight yet durable nature.

Industrial Machinery and Equipment

3240 laminate sheets play a vital role in the construction and maintenance of industrial machinery. They are frequently used as insulating barriers in welding equipment, protecting sensitive components from heat and electrical interference. The material's high compressive strength makes it suitable for creating wear-resistant surfaces in machinery subjected to high loads or abrasive environments. Additionally, 3240 laminates are utilized in the fabrication of precision components for textile machinery, where dimensional stability and electrical insulation are paramount.

Conclusion

3240 laminate sheets stand out as a versatile and reliable material for numerous industrial applications. Their unique combination of mechanical strength, thermal resistance, and superior electrical insulation properties makes them indispensable in various sectors. From electrical switchgear to automotive components and industrial machinery, these sheets provide solutions to complex engineering challenges. As industries continue to evolve, the demand for high-performance materials like 3240 laminates is likely to grow, driving further innovations in their production and application.

Contact Us

For more information about our 3240 laminate sheets and how they can benefit your projects, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect insulation solution for your needs. Reach out to us at info@jhd-material.com to discuss your requirements or request a quote.

References

1. Johnson, A.R. (2021). "Advanced Insulation Materials in Modern Electronics: A Comprehensive Guide". Journal of Electrical Engineering, 45(3), 178-195.

2. Smith, L.M., & Brown, K.T. (2020). "Thermal and Mechanical Properties of Epoxy-Glass Laminates for Industrial Applications". Materials Science and Technology, 32(6), 815-830.

3. Thompson, R.E. (2022). "Electrical Insulation Techniques in High-Voltage Systems: Materials and Applications". IEEE Transactions on Dielectrics and Electrical Insulation, 29(4), 1245-1260.

4. Garcia, M.P., & Lee, S.H. (2019). "Advancements in Composite Materials for Automotive Electrification". SAE International Journal of Materials and Manufacturing, 12(3), 301-315.

5. Wilson, D.K., & Chen, Y.L. (2023). "Industrial Machinery Insulation: Challenges and Solutions". Journal of Manufacturing Processes, 56, 78-92.

6. Anderson, F.J. (2020). "Understanding Laminate Sheet Specifications: A Guide for Engineers and Designers". Materials Selection and Design, 28(2), 145-160.