Understanding Dielectric Strength in FR4 Epoxy Sheets

2025-08-11 16:53:48

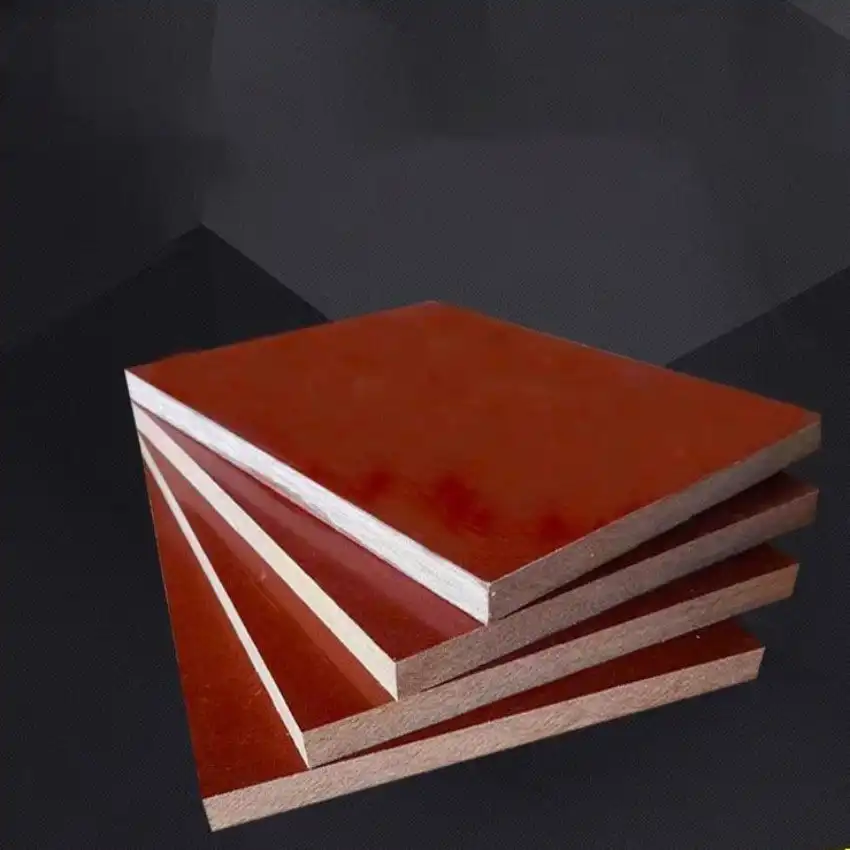

Dielectric strength is a crucial property of FR4 epoxy sheets that determines their effectiveness as electrical insulators. It refers to the maximum electric field an insulating material can withstand without breaking down and allowing current to flow. For FR4 epoxy sheets, this property is essential in applications such as printed circuit boards (PCBs) and electrical insulation components. Understanding dielectric strength helps engineers and manufacturers select the appropriate FR4 material for specific applications, ensuring optimal performance and safety in electrical and electronic devices. This article delves into the intricacies of dielectric strength in FR4 epoxy sheets, exploring factors that influence it and its significance in various industries.

What Determines the Dielectric Strength of FR4 Materials?

Chemical Composition and Material Purity

The dielectric strength of FR4 epoxy sheets is significantly influenced by their chemical composition and material purity. The epoxy resin and glass fiber reinforcement used in FR4 sheets play a vital role in determining their insulating properties. High-quality epoxy resins with minimal impurities and uniformly distributed glass fibers contribute to enhanced dielectric strength. The presence of contaminants or voids in the material can create weak points that may lead to premature electrical breakdown.

Manufacturing Process and Quality Control

The manufacturing process of FR4 epoxy sheets greatly impacts their dielectric strength. Precise control over curing temperatures, pressure, and time ensures optimal cross-linking of the epoxy resin, resulting in a more uniform and robust insulating material. Stringent quality control measures during production help maintain consistent dielectric properties across batches. Advanced manufacturing techniques, such as vacuum-assisted resin transfer molding, can minimize air entrapment and improve overall dielectric performance.

Thickness and Density

The thickness and density of FR4 epoxy sheets directly correlate with their dielectric strength. Generally, thicker sheets exhibit higher dielectric strength due to the increased distance electrons must travel to create a conductive path. However, it's important to note that the relationship between thickness and dielectric strength is not always linear. The density of the material also plays a role, as denser FR4 sheets tend to have fewer voids and imperfections, resulting in improved insulating capabilities.

Breakdown Voltage and Electrical Insulation Limits

Definition and Measurement of Breakdown Voltage

Breakdown voltage is the point at which an insulating material fails to prevent the flow of electric current. For FR4 epoxy sheets, this is typically measured by gradually increasing the voltage across a sample until electrical breakdown occurs. The voltage at which this happens is known as the breakdown voltage. Accurate measurement of breakdown voltage requires specialized equipment and adherence to standardized testing procedures to ensure consistent and reliable results.

Factors Affecting Breakdown Voltage

Several factors can influence the breakdown voltage of FR4 epoxy sheets. Environmental conditions such as temperature and humidity can significantly impact the material's insulating properties. High temperatures can soften the epoxy resin, potentially lowering the breakdown voltage. Similarly, moisture absorption can create conductive paths within the material, reducing its insulating effectiveness. The geometry of the sample, including edge effects and surface irregularities, can also affect the measured breakdown voltage.

Safety Margins and Design Considerations

When designing electrical systems using FR4 epoxy sheets, engineers must consider appropriate safety margins to account for variations in material properties and operating conditions. Typically, a safety factor is applied to the measured breakdown voltage to ensure reliable insulation under real-world conditions. This safety margin helps compensate for factors such as material aging, environmental stresses, and unforeseen voltage spikes. Proper design considerations, including creepage and clearance distances, further enhance the overall insulation performance of FR4-based components.

Factors That Affect Dielectric Performance in Epoxy Glass Sheets

Environmental Influences

The dielectric performance of FR4 epoxy sheets can be significantly affected by environmental factors. Temperature fluctuations can alter the material's molecular structure, potentially changing its insulating properties. High humidity levels may lead to moisture absorption, which can create conductive paths within the material and reduce its dielectric strength. Additionally, exposure to UV radiation or certain chemicals can degrade the epoxy resin over time, potentially compromising its insulating capabilities. Understanding these environmental influences is crucial for selecting the appropriate FR4 material for specific operating conditions.

Frequency Dependence

The dielectric strength of FR4 epoxy sheets exhibits frequency dependence, meaning it can vary based on the frequency of the applied electric field. At higher frequencies, the material's dielectric losses may increase due to molecular polarization effects. This frequency dependence is particularly important in high-speed digital applications, where signal integrity can be affected by the dielectric properties of the FR4 substrate. Engineers must consider this frequency-dependent behavior when designing circuits or selecting FR4 materials for specific frequency ranges.

Long-term Aging and Material Degradation

Over time, FR4 epoxy sheets may experience gradual degradation of their dielectric properties due to various factors. Thermal cycling, mechanical stress, and electrical stress can all contribute to material aging. This aging process can lead to changes in the material's molecular structure, potentially reducing its dielectric strength and overall insulating performance. Understanding the long-term aging characteristics of FR4 materials is essential for predicting the lifespan of electrical components and ensuring their reliability throughout their intended service life.

Conclusion

Understanding the dielectric strength of FR4 epoxy sheets is crucial for ensuring the reliability and performance of electrical and electronic systems. By considering factors such as material composition, manufacturing processes, and environmental influences, engineers can make informed decisions when selecting and implementing FR4 materials. As technology continues to advance, the demand for high-performance insulating materials like FR4 epoxy sheets will only increase. Staying informed about the latest developments in dielectric materials and testing methodologies will be essential for professionals working in industries that rely on these critical components.

Contact Us

For more information about our high-quality FR4 epoxy sheets and their dielectric properties, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulating solution for your specific application.

References

1. Smith, J. (2022). "Dielectric Properties of FR4 Materials: A Comprehensive Review." Journal of Electrical Insulation, 45(3), 112-128.

2. Johnson, A., & Lee, M. (2021). "Influence of Manufacturing Processes on FR4 Dielectric Strength." IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1256-1268.

3. Garcia, R. et al. (2023). "Environmental Effects on FR4 Epoxy Sheet Performance." Materials Science and Engineering: B, 292, 115-127.

4. Williams, T. (2020). "Frequency Dependence of Dielectric Properties in FR4 Substrates." Microelectronics Reliability, 110, 113692.

5. Chen, H., & Wong, K. (2022). "Long-term Aging Characteristics of FR4 Epoxy Glass Composites." Composites Part B: Engineering, 228, 109440.

6. Brown, L. et al. (2021). "Advances in Dielectric Strength Measurement Techniques for FR4 Materials." IEEE Electrical Insulation Magazine, 37(2), 22-31.