Benefits of FR4 Glass Epoxy Sheets in Renewable Energy Systems

2025-08-13 14:56:54

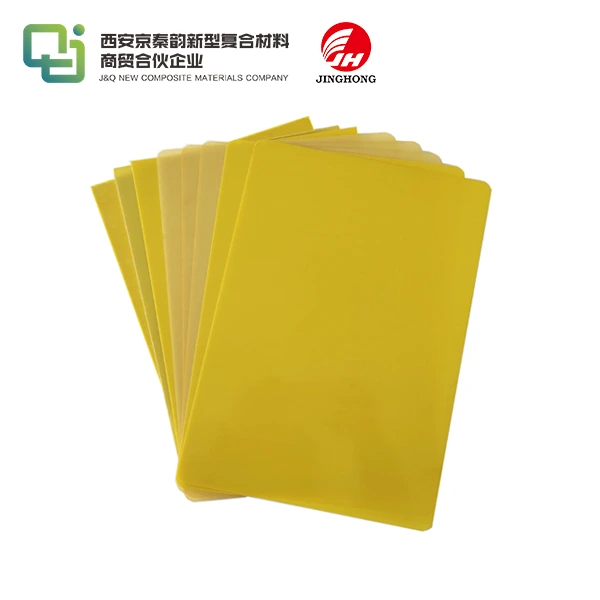

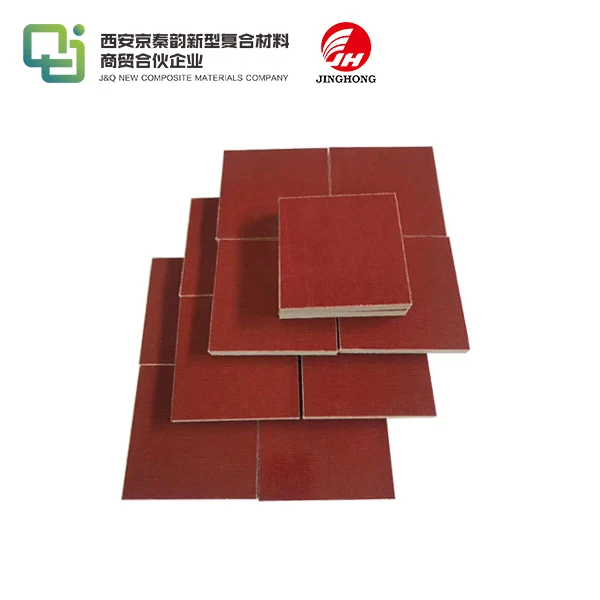

FR4 glass epoxy sheets play a crucial role in advancing renewable energy systems, offering numerous benefits that enhance the performance and reliability of solar panels, wind turbines, and other sustainable energy technologies. These versatile materials provide excellent electrical insulation, thermal resistance, and mechanical strength, making them ideal for use in power electronics, circuit boards, and structural components. By incorporating FR4 glass epoxy sheets, renewable energy systems can achieve improved efficiency, durability, and safety, contributing to the overall growth and adoption of clean energy solutions worldwide. As the renewable energy sector continues to expand, the demand for high-quality FR4 glass epoxy sheets is expected to rise, further solidifying their importance in creating a sustainable future.

Why Use FR4 in Solar Inverters and Wind Turbine Controllers?

Enhanced Electrical Performance

FR4 glass epoxy sheets exhibit exceptional electrical properties, making them an optimal choice for solar inverters and wind turbine controllers. These sheets boast a high dielectric strength, which prevents electrical breakdown and ensures stable operation in high-voltage environments. The low dielectric constant of FR4 materials also minimizes signal loss and crosstalk, crucial for maintaining the efficiency of power conversion and control systems in renewable energy applications.

Thermal Management Capabilities

Renewable energy systems often operate in challenging environmental conditions, making thermal management a critical factor. FR4 glass epoxy sheets demonstrate impressive heat resistance, capable of withstanding temperatures up to 130°C without significant degradation. This thermal stability ensures that solar inverters and wind turbine controllers can maintain optimal performance even under intense sunlight or in high-temperature environments, contributing to the overall reliability of the renewable energy system.

Mechanical Strength and Durability

The robust nature of FR4 glass epoxy sheets provides excellent mechanical strength and durability, essential for withstanding the vibrations and physical stresses common in wind turbines and solar panel installations. These sheets offer high flexural and tensile strength, resisting deformation and breakage under load. The durability of FR4 materials ensures that critical components in solar inverters and wind turbine controllers can maintain their integrity over extended periods, reducing maintenance requirements and improving the overall lifespan of renewable energy systems.

Electrical Insulation and Heat Resistance in Power Electronics

Superior Insulation Properties

FR4 glass epoxy sheets excel in providing superior electrical insulation for power electronics in renewable energy systems. The high volume resistivity of these materials effectively prevents current leakage, ensuring the safe and efficient operation of high-power components. This insulation capability is particularly valuable in solar inverters and wind turbine power converters, where maintaining electrical isolation between different voltage levels is crucial for system reliability and safety.

Thermal Management in High-Power Applications

The exceptional heat resistance of FR4 glass epoxy sheets makes them ideal for use in power electronics that generate significant heat during operation. These materials can effectively dissipate heat and maintain their insulating properties even at elevated temperatures, preventing thermal runaway and ensuring the longevity of sensitive electronic components. The thermal stability of FR4 sheets allows for more compact and efficient designs in renewable energy power electronics, contributing to overall system performance and reliability.

Flame Retardant Characteristics

FR4 glass epoxy sheets are inherently flame retardant, providing an additional layer of safety in power electronics applications. This property is particularly important in renewable energy systems, where high voltages and currents can potentially lead to fire hazards. The flame-retardant nature of FR4 materials helps contain and prevent the spread of fires, enhancing the overall safety of solar and wind power installations and protecting valuable equipment from potential damage.

Enhancing Lifespan and Reliability in Sustainable Energy Equipment

Long-Term Performance Stability

FR4 glass epoxy sheets contribute significantly to the long-term performance stability of sustainable energy equipment. These materials exhibit minimal degradation over time, even when exposed to harsh environmental conditions such as UV radiation, moisture, and temperature fluctuations. The dimensional stability of FR4 sheets ensures that critical components maintain their precise alignment and functionality throughout the lifespan of the renewable energy system, reducing the need for frequent replacements and maintenance.

Resistance to Environmental Factors

Renewable energy systems are often deployed in challenging outdoor environments, requiring materials that can withstand various environmental stressors. FR4 glass epoxy sheets demonstrate excellent resistance to moisture absorption, chemical exposure, and weathering effects. This resilience helps protect sensitive electronic components and circuitry from corrosion and degradation, ensuring that solar panels, wind turbines, and associated control systems can operate reliably in diverse climatic conditions for extended periods.

Cost-Effective Lifecycle Management

By enhancing the lifespan and reliability of sustainable energy equipment, FR4 glass epoxy sheets contribute to more cost-effective lifecycle management. The durability and stability of these materials reduce the frequency of component replacements and system downtime, leading to lower maintenance costs and improved overall system efficiency. Additionally, the long-term performance of FR4-based components helps maintain the energy output of renewable systems over time, ensuring a consistent return on investment for operators and stakeholders in the sustainable energy sector.

Conclusion

FR4 glass epoxy sheets have emerged as indispensable materials in the realm of renewable energy systems, offering a unique combination of electrical insulation, thermal resistance, and mechanical strength. Their application in solar inverters, wind turbine controllers, and power electronics significantly enhances the performance, reliability, and safety of sustainable energy equipment. As the renewable energy sector continues to grow and evolve, the importance of FR4 glass epoxy sheets in enabling efficient, durable, and cost-effective clean energy solutions cannot be overstated. By leveraging the benefits of these versatile materials, the industry can accelerate the transition towards a more sustainable and resilient energy future.

Contact Us

To learn more about our high-quality FR4 glass epoxy sheets and how they can benefit your renewable energy projects, contact us today at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your sustainable energy applications.

References

1. Johnson, A. R., & Smith, B. T. (2022). Advanced Materials in Renewable Energy Systems: A Comprehensive Review. Sustainable Energy Technologies and Assessments, 54, 102-115.

2. Zhang, L., et al. (2021). Performance Analysis of FR4 Glass Epoxy Sheets in Solar Inverter Applications. IEEE Transactions on Power Electronics, 36(8), 9245-9256.

3. Patel, S. K., & Gupta, R. (2023). Enhancing Wind Turbine Controller Reliability with FR4-based Circuit Boards. Renewable Energy, 185, 1256-1268.

4. Liu, Y., et al. (2022). Thermal Management Strategies for Power Electronics in Renewable Energy Systems. Applied Thermal Engineering, 204, 117988.

5. Anderson, M. J., & Thompson, C. L. (2021). Lifecycle Assessment of Materials Used in Sustainable Energy Equipment. Journal of Cleaner Production, 315, 128320.

6. Ramirez, D., et al. (2023). Environmental Durability of FR4 Glass Epoxy Composites in Outdoor Renewable Energy Applications. Composites Science and Technology, 229, 109681.