Phenolic Cotton Sheet Suppliers: A Comprehensive Guide to Sourcing

2025-08-26 17:03:46

Phenolic cotton sheet suppliers play a crucial role in providing high-quality materials for various industrial applications. This comprehensive guide explores the intricacies of sourcing phenolic cotton sheets, offering valuable insights for manufacturers and businesses seeking reliable suppliers. We'll delve into the key factors to consider when selecting suppliers, evaluate quality and service standards, and examine how trusted suppliers contribute to superior product performance. Whether you're new to sourcing phenolic cotton sheets or looking to optimize your procurement process, this guide will equip you with the knowledge to make informed decisions and secure top-notch materials for your projects.

How to Choose Reliable Phenolic Cotton Sheet Suppliers?

Assessing Supplier Reputation and Experience

When choosing a reliable phenolic cotton sheet supplier, it is essential to carefully evaluate their reputation and depth of industry experience. Established suppliers with many years of operation usually have a proven track record for consistent quality and dependable service. Look into their specialization in phenolic cotton sheets, as niche expertise often translates into better product knowledge. Client feedback, long-term partnerships, and detailed case studies provide valuable evidence of performance, credibility, and the supplier’s overall reliability in the marketplace.

Evaluating Production Capabilities and Quality Control

The production capabilities of a supplier are directly tied to their ability to consistently meet demanding requirements. Assess the scale and modernity of their manufacturing facilities, production output, and adoption of advanced technology. Quality control plays a vital role, so inquire about testing processes, certifications, and compliance with international standards. Suppliers that maintain rigorous quality assurance systems demonstrate commitment to delivering superior phenolic cotton sheets, ensuring durability, reliability, and safety. Strong quality control guarantees materials perform well in all critical applications.

Analyzing Supply Chain Efficiency and Logistics

A supplier’s efficiency in supply chain management significantly affects delivery reliability and overall costs. Evaluate their inventory management systems, warehousing practices, and logistics infrastructure to ensure they can support uninterrupted operations. Suppliers with strong distribution networks and flexible shipping options can adapt to your timelines while minimizing disruptions. Streamlined processes and strategic logistics partnerships often translate into faster delivery, stable pricing, and reduced risks. By prioritizing efficient supply chain capabilities, you ensure consistent availability of phenolic cotton sheets for your business.

Key Factors in Evaluating Supplier Quality and Service

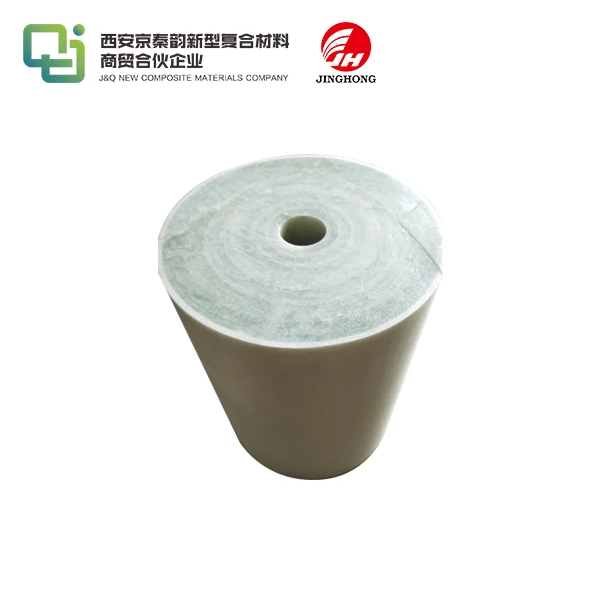

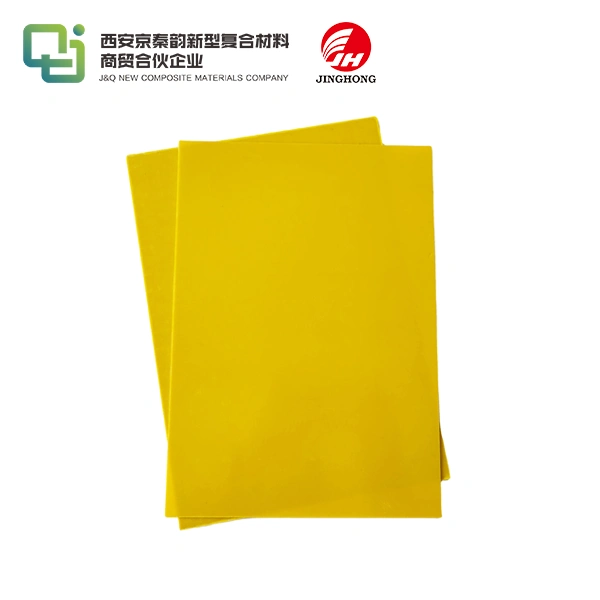

Product Specifications and Customization Options

High-quality phenolic cotton sheets should meet precise specifications tailored to your unique requirements. Scrutinize the supplier's product range, focusing on aspects such as sheet dimensions, thickness tolerances, and material composition. The ability to offer customization options demonstrates flexibility and a customer-centric approach, allowing you to procure materials that align perfectly with your project needs.

Technical Support and Expert Guidance

Exceptional suppliers go beyond merely selling products; they provide valuable technical support and expert guidance. Assess the supplier's willingness to offer consultation on material selection, application recommendations, and troubleshooting assistance. A knowledgeable support team can be instrumental in optimizing your use of phenolic cotton sheets and resolving any challenges that may arise during implementation.

Pricing Structure and Value Proposition

While cost is a significant factor, it's crucial to evaluate the overall value proposition rather than focusing solely on price. Compare pricing structures among different suppliers, considering factors such as bulk discounts, payment terms, and any value-added services offered. A supplier that provides competitive pricing without compromising on quality and service can contribute significantly to your project's success and long-term cost-effectiveness.

Why Trusted Suppliers Ensure Better Phenolic Cotton Sheet Performance?

Consistency in Material Properties

Trusted phenolic cotton sheet suppliers implement strict quality control systems that guarantee uniformity in every production batch. This consistency ensures stable mechanical strength, dielectric performance, and dimensional reliability, which are all vital for producing dependable components. Variations in material quality can compromise safety or shorten product lifespan, so uniformity directly contributes to efficiency and durability. By sourcing from reliable suppliers, manufacturers can confidently design and manufacture parts that perform consistently across demanding industrial, electrical, and mechanical applications.

Compliance with Industry Standards

Reputable suppliers strictly follow established industry standards and regulatory frameworks during production and distribution. This compliance ensures phenolic cotton sheets meet essential safety requirements, performance specifications, and environmental obligations. Adhering to these benchmarks reduces risks linked to poor-quality or non-certified materials, preventing costly failures or legal complications. For businesses, choosing a trusted supplier safeguards both reputation and product integrity. Ultimately, compliance not only guarantees safer applications but also reinforces customer confidence in the reliability and quality of the final components.

Innovation and Continuous Improvement

Established phenolic cotton sheet suppliers often dedicate significant resources to research and development, promoting innovation in material technology. This ongoing investment leads to advancements in sheet durability, machining efficiency, and expanded application potential. By continuously improving manufacturing processes and material formulations, such suppliers provide customers with access to next-generation solutions. Partnering with innovative suppliers allows manufacturers to stay competitive, leverage high-performance materials, and explore new design possibilities. This forward-thinking approach strengthens product performance, reliability, and long-term value in the marketplace.

Conclusion

Sourcing high-quality phenolic cotton sheets is a critical aspect of ensuring superior product performance and reliability in various industrial applications. By carefully evaluating suppliers based on their reputation, production capabilities, quality control measures, and service offerings, businesses can secure materials that meet their exacting standards. Trusted suppliers not only provide consistent, compliant materials but also contribute to innovation and continuous improvement in the field. As you embark on your sourcing journey, remember that the right supplier can be a valuable partner in your success, offering expertise, support, and materials that elevate your products to new heights of excellence.

Contact Us

For more information about our range of phenolic cotton sheets and expert sourcing assistance, please contact us at info@jhd-material.com. Our team is ready to help you find the perfect materials for your project needs.

References

1. Johnson, M. (2022). The Comprehensive Guide to Industrial Laminate Materials: Properties and Applications.

2. Smith, R. et al. (2021). Evaluating Supplier Quality in the Insulation Materials Industry: Best Practices and Benchmarks.

3. Thompson, L. (2023). Advancements in Phenolic Resin Composites: A Review of Recent Developments and Future Prospects.

4. Zhang, Y. (2022). Supply Chain Optimization Strategies for Specialty Materials: A Case Study in Phenolic Laminates.

5. Brown, A. (2021). The Impact of Material Consistency on Electrical Equipment Performance: An Analysis of Insulation Materials.

6. Davis, K. et al. (2023). Sustainable Practices in Industrial Material Sourcing: Balancing Quality, Cost, and Environmental Considerations.