How Phenolic Laminated Sheets Are Used in Switchgear Manufacturing?

2025-09-08 16:47:56

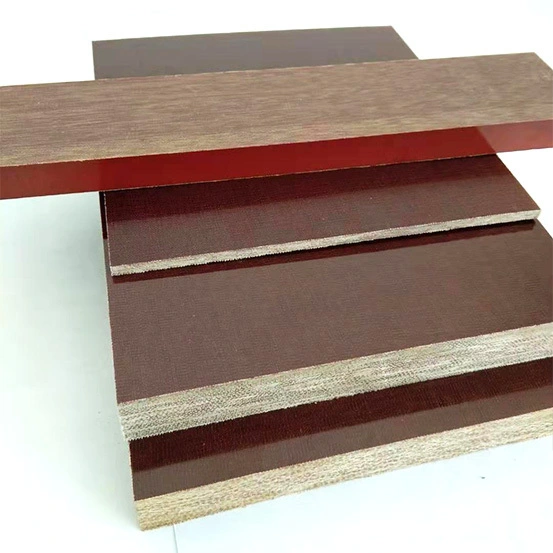

Phenolic laminated sheets play a crucial role in switchgear manufacturing, serving as essential components for electrical insulation and structural support. These versatile materials are widely used in the production of various switchgear elements, including panels, barriers, and insulators. The exceptional properties of phenolic laminated sheets, such as high dielectric strength, excellent thermal stability, and superior mechanical strength, make them ideal for ensuring the safety and reliability of switchgear systems. By incorporating these sheets into switchgear designs, manufacturers can enhance the overall performance, durability, and longevity of electrical distribution equipment, ultimately contributing to the efficient and safe operation of power systems.

What Role Do Phenolic Sheets Play in Switchgear Safety?

Electrical Insulation Excellence

Phenolic laminated sheets are widely recognized for their exceptional electrical insulation properties, making them ideal for use in switchgear assemblies. Their high dielectric strength effectively isolates conductive elements, significantly reducing the risk of electrical leakage and short circuits. This reliable insulation is essential for ensuring the operational safety and longevity of switchgear systems. By preventing unintended current flow, these sheets help protect sensitive equipment and reduce hazards to personnel, thereby supporting consistent performance in electrical applications.

Mechanical Strength and Durability

The inherent mechanical robustness of phenolic laminated sheets plays a key role in reinforcing the structural integrity of switchgear systems. These materials exhibit outstanding resistance to impact, compression, and flexural stresses, enabling them to withstand harsh operating environments without deformation or failure. This durability ensures that critical components remain securely in place, reducing the likelihood of mechanical malfunctions. As a result, switchgear systems maintain higher reliability and require less maintenance over their service life.

Fire Resistance and Safety

Thanks to their naturally fire-resistant composition, phenolic laminated sheets provide an important layer of safety in switchgear applications. In cases of electrical faults or overheating, these sheets resist ignition and help restrict the spread of fire, thereby minimizing potential damage. This capability is especially critical in high-voltage settings where fire hazards pose serious risks to both infrastructure and personnel. Incorporating phenolic sheets enhances overall system resilience and supports compliance with stringent safety standards.

Arc Resistance, Dielectric Properties, and Thermal Stability

Arc Resistance Capabilities

One of the most critical attributes of phenolic laminated sheets in switchgear applications is their exceptional arc resistance. These sheets are engineered to endure extreme thermal and mechanical stresses caused by electrical arcs, effectively resisting erosion and carbon tracking. By preventing the formation of conductive pathways, they help maintain insulation integrity and significantly reduce the risk of short circuits or equipment damage. This capability is vital for enhancing operational safety in environments where arc flash events may occur, thereby supporting the long-term reliability and functionality of switchgear systems.

Superior Dielectric Strength

Phenolic laminated sheets are widely valued for their outstanding dielectric strength, which makes them particularly suitable for high-voltage switchgear applications. They provide reliable insulation even when subjected to intense electric fields, effectively preventing current leakage and electrical breakdown between energized and grounded components. This strong dielectric performance ensures stable voltage isolation and reduces the likelihood of failures, contributing to the overall safety, efficiency, and durability of electrical switchgear systems.

Thermal Stability Under Extreme Conditions

A key advantage of phenolic laminated sheets is their excellent thermal stability, which allows them to perform consistently across a broad temperature spectrum. Whether exposed to high heat generated during electrical operations or colder ambient conditions, these materials retain their structural and insulating properties. This resilience helps prevent thermal degradation, distortion, or loss of function, making them ideal for use in switchgear that must endure fluctuating operational temperatures while maintaining reliability over extended periods.

Practical Applications in Panels, Insulators, and Structural Parts

Switchgear Panels and Enclosures

Phenolic laminated sheets are extensively used in the construction of switchgear panels and enclosures. These sheets provide a sturdy, insulating foundation for mounting electrical components and bus bars. The combination of electrical insulation and mechanical strength offered by phenolic sheets ensures that switchgear panels can safely house and protect critical electrical equipment while maintaining proper electrical clearances and creepage distances.

Insulating Barriers and Partitions

Within switchgear assemblies, phenolic laminated sheets serve as effective insulating barriers and partitions. These components are crucial for segregating different voltage levels and phases, preventing arc propagation between compartments, and enhancing overall safety. The versatility of phenolic sheets allows for custom fabrication of barriers and partitions to suit specific switchgear designs and configurations, ensuring optimal insulation and protection.

Structural Support and Mounting Plates

The mechanical strength and dimensional stability of phenolic laminated sheets make them excellent candidates for structural support elements and mounting plates in switchgear. These components provide a secure foundation for attaching various electrical devices, such as circuit breakers, relays, and control units. The use of phenolic sheets in these applications ensures proper insulation between mounted components and the switchgear frame, while also offering the necessary strength to withstand operational stresses and vibrations.

Conclusion

Phenolic laminated sheets have become indispensable in switchgear manufacturing due to their exceptional electrical, mechanical, and thermal properties. Their versatility in applications ranging from insulation barriers to structural components significantly enhances the safety, reliability, and performance of switchgear systems. As the demand for more efficient and compact electrical distribution equipment continues to grow, the role of phenolic laminated sheets in switchgear manufacturing is likely to expand, driving innovations in design and functionality.

Contact Us

To learn more about our high-quality phenolic laminated sheets for switchgear applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your switchgear manufacturing needs.

References

1. Smith, J. (2022). Advanced Materials in Electrical Equipment: A Comprehensive Guide to Phenolic Laminates.

2. Johnson, R., & Brown, L. (2021). Switchgear Design Principles: Incorporating Phenolic Sheets for Enhanced Safety.

3. Electrical Engineering Institute. (2023). Insulation Technologies in Modern Switchgear: The Role of Phenolic Laminates.

4. Thompson, M. (2020). Arc Flash Protection Strategies: Utilizing Phenolic Sheets in Switchgear Manufacturing.

5. International Electrotechnical Commission. (2022). Standards for Insulating Materials in Switchgear Applications.

6. Lee, S., & Parker, T. (2021). Thermal Management in High-Voltage Switchgear: Advantages of Phenolic Laminated Materials.