Can FR4 Epoxy Board Be Used for Thick Structural Parts?

2026-01-16 16:34:47

Yes, FR4 epoxy board can be utilized for thick structural components; nevertheless, the success of this application greatly depends on the choice of materials, design factors, and production processes. The remarkable mechanical strength, electrical insulation qualities, and thermal stability of this glass-reinforced epoxy laminate material make it appropriate for demanding structural applications in a variety of industries. This thorough guide gives procurement managers, engineers, distributors, and OEM clients crucial information about the potential and constraints of FR4 for thick structural components.

When choosing suitable materials for industrial production applications where mechanical integrity and thermal stability cannot be compromised, it becomes crucial to comprehend these characteristics. Informed sourcing decisions that balance performance requirements, reliability standards, and cost efficiency considerations across global B2B supply chains are made possible by the information provided here. Materials that can perform multiple functions while maintaining structural integrity under demanding operating conditions are becoming more and more necessary in modern industrial applications. Because of their special combination of qualities, FR4 epoxy boards satisfy these requirements and are useful substitutes for conventional structural materials in particular applications.

Understanding FR4 Epoxy Board: Properties and Suitability for Structural Use

Chemical Composition and Core Structure

The strength of glass fibers and the binding qualities of thermoset polymers are combined in FR4 epoxy board, a composite material made of woven fiberglass fabric soaked with flame-retardant epoxy resin. The number "4" denotes the particular grade of woven glass material used in construction, while the "FR" label denotes flame-retardant qualities. For a wide variety of thicknesses, this composition offers remarkable mechanical performance and dimensional stability.

Tensile strength and rigidity are provided by the glass fiber reinforcement, and superior adhesion, chemical resistance, and dielectric qualities are provided by the epoxy matrix. Power distribution components, motor housings, and industrial machinery parts benefit greatly from this combination since it produces a material that is especially well-suited for applications needing both structural support and electrical insulation.

Mechanical Performance Characteristics

Assessing FR4's potential for thick structural applications requires an understanding of its mechanical characteristics. Depending on thickness and manufacturing conditions, the material's tensile strength can reach 310 to 380 MPa, while its flexural strength values commonly range from 415 to 540 MPa. These figures show that FR4 can support heavy mechanical loads without losing dimensional precision.

For structural applications, impact resistance and fatigue performance are further benefits. FR4 is appropriate for industrial machinery subjected to thermal cycling, power generation equipment, and automotive components since it retains its mechanical qualities over temperature ranges of -40°C to 130°C. Because of its low rate of moisture absorption, the material performs consistently under a range of humidity levels.

Thermal and Electrical Insulation Properties

FR4 is very useful for applications involving heat dissipation and thermal barriers because of its thermal performance. FR4 can withstand harsh heat conditions without compromising structural integrity, with a glass transition temperature of approximately 130–140°C and a continuous operating temperature of up to 130°C. Because of the material's very low coefficient of thermal expansion, dimensional changes during temperature swings are minimized.

Outstanding electrical insulation capabilities are provided by dielectric strengths greater than 20 kV/mm and volume resistivity larger than 10^14 ohm-cm. Because of these characteristics, thick FR4 boards are perfect for motor insulation systems, switchgear assemblies, and transformer components where electrical safety cannot be compromised.

Assessing FR4 Epoxy Board for Thick Structural Parts: Challenges and Solutions

Common Challenges in Thick Section Applications

During the design and manufacturing stages, engineering teams face unique problems when working with thick FR4 parts. Thick materials have a greater concentration of thermal stress, which may result in internal stress accumulation and dimensional instability. Curing cycles and cooling rates must be carefully considered during the production process in order to avoid warping and preserve consistent characteristics across the thickness of the material.

The likelihood of delamination rises with thickness, especially when materials are subjected to mechanical stress or thermal cycling. To ensure proper inter-layer bonding, this challenge calls for improved quality control procedures and maybe altered resin formulas. In order to avoid chipping and preserve dimensional tolerances, CNC machining of thick FR4 sections also requires specific tools and cutting conditions.

Here are the key manufacturing considerations for thick FR4 applications:

• Controlled curing processes that ensure uniform resin distribution and prevent internal voids or stress concentrations throughout the material thickness

• Specialized tooling requirements for machining operations that maintain surface finish quality while preventing delamination during cutting processes

• Quality assurance protocols including ultrasonic testing and thermal imaging to detect internal defects before parts reach final assembly stages

These manufacturing controls directly impact the reliability and performance of thick FR4 structural components in demanding industrial environments.

Quality Assurance and Certification Standards

Adherence to industry standards and thorough testing procedures for FR4 epoxy board are necessary to guarantee consistent quality in thick FR4 boards. Benchmarks for material acceptability are provided by ASTM mechanical testing standards, IPC electrical property criteria, and UL 94 flame retardancy ratings. In the automobile, aerospace, and power generation industries, where component failure could have dire repercussions, these certifications become more crucial.

Batch consistency and material traceability are important considerations for procurement teams overseeing extensive manufacturing operations. In addition to providing paperwork that supports quality management systems and regulatory compliance requirements, suppliers must show that they are able to maintain consistent qualities across production runs.

Real-World Application Case Studies

Thick FR4 boards have been successfully used in structural applications, demonstrating the material's adaptability and performance potential. FR4 sheets up to 50 mm thick are used in power distribution systems for arc barriers and bus bar insulation, where the combination of electrical and mechanical strength is crucial for safe operation.

Gear housings and bearing supports are examples of industrial equipment applications where FR4 outperforms conventional materials due to its dimensional stability and wear resistance. These cases demonstrate how the difficulties of using thick sections can be addressed while providing improved performance characteristics through careful material selection and technical design.

How to Choose the Best FR4 Epoxy Board for Thick Structural Applications

Evaluating Mechanical Performance by Thickness

A thorough examination of how mechanical properties alter with increasing thickness is necessary for choosing suitable FR4 materials for thick structural components. Thick sections may display differences in flexural modulus and impact resistance due to production factors and internal stress distribution, but thin FR4 sheets display predictable qualities. When determining design margins and safety factors, engineering teams must take these aspects into account.

For load-bearing applications, the link between thickness and mechanical performance becomes very crucial. Under prolonged loading circumstances, thick FR4 boards frequently exhibit improved compression strength while retaining superior dimensional stability. Engineers can optimize part design while guaranteeing sufficient performance margins for safety-critical applications by having a thorough understanding of these features.

Supplier Evaluation and Certification Requirements

Selecting trustworthy FR4 suppliers requires assessing technical support services, quality processes, and manufacturing capabilities. While strictly adhering to requirements, suppliers must exhibit consistent production capabilities over the whole range of required thicknesses. Industry-specific standards and ISO 9001 quality management certification guarantee manufacturing uniformity and quality control.

The ability to provide technical help becomes crucial when dealing with thick FR4 applications. When standard grades do not satisfy particular application needs, suppliers should provide technical consultation services, support for material testing, and bespoke formulation capabilities. This cooperative method lowers development expenses and time while optimizing material selection.

Cost Considerations and Value Engineering

Understanding the total cost of ownership, as opposed to just material pricing, is necessary to strike a balance between cost and performance requirements. FR4's durability, machinability, and multifunctional qualities can offer better value in difficult applications, even though its initial prices may be greater than those of other alternatives. Secondary processes and assembly steps can be eliminated by combining structural and insulating functions into a single component.

Because thick FR4 boards require lengthy curing cycles and quality verification procedures during production, lead time issues become especially crucial. To guarantee that material availability corresponds with production schedules, procurement teams should set suitable inventory levels and collaborate closely with suppliers. In addition to guaranteeing priority access to commodities during times of high demand, long-term supply agreements can stabilize prices.

Optimizing Performance of Thick FR4 Epoxy Boards in Structural Parts

Design Strategies for Enhanced Performance

Careful consideration of design features that take into account material properties and application requirements is necessary to maximize the performance of thick FR4 boards in structural applications. In thick sections, stress concentration considerations become more important, requiring extensive radius specifications at transitions and corners. When these aspects are properly attended to, crack start is prevented and long-term reliability under cyclic loading circumstances is guaranteed.

As thickness grows, considerations of thermal management become more significant. Thermal expansion coefficients and features that adapt to dimensional changes without causing undue stress should be included in design plans. Applications involving temperature cycling or components positioned between materials with varying rates of thermal expansion make this strategy more crucial.

Engineering Best Practices and Manufacturing Techniques

Thick FR4 structural components for FR4 epoxy board must be implemented successfully by following tried-and-true engineering procedures and production methods. Mechanical qualities are impacted by lamination orientation, which should be determined by the main stress directions. For applications involving multidirectional stress, cross-ply designs frequently offer the best possible combination between strength and dimensional stability.

Controls over the manufacturing process guarantee uniform performance and quality throughout production batches. Before machining operations, materials should be properly preheated to minimize thermal stress and avoid cracking. To preserve surface finish quality while avoiding delamination throughout fabrication operations, tool selection and cutting settings must be tuned for FR4's particular features.

Testing Protocols and Quality Verification

Before being deployed in crucial applications, thorough testing procedures confirm that thick FR4 components fulfill performance requirements. Tensile, flexural, and impact tests carried out at the appropriate operating temperatures should all be part of mechanical testing. Electrical testing confirms insulation resistance and dielectric strength across component thickness.

Protocols for environmental testing assess performance in the presence of moisture, heat cycling, and accelerated aging. While identifying possible failure modes that might not be visible during the initial performance review, these tests offer assurance in long-term reliability. Test result documentation facilitates regulatory compliance needs and promotes quality management systems.

Company Introduction and Our FR4 Epoxy Board Solutions

J&Q's Expertise and Manufacturing Capabilities

With more than ten years of dedicated attention to global markets, J&Q delivers more than two decades of experience in manufacturing and marketing premium insulation products. We are able to offer complete services that satisfy the various needs of international business-to-business (B2B) clients because of our vast experience in foreign trading and our collaborations with numerous local and international trading organizations. This knowledge results in a thorough comprehension of technical criteria and market demands across many industries.

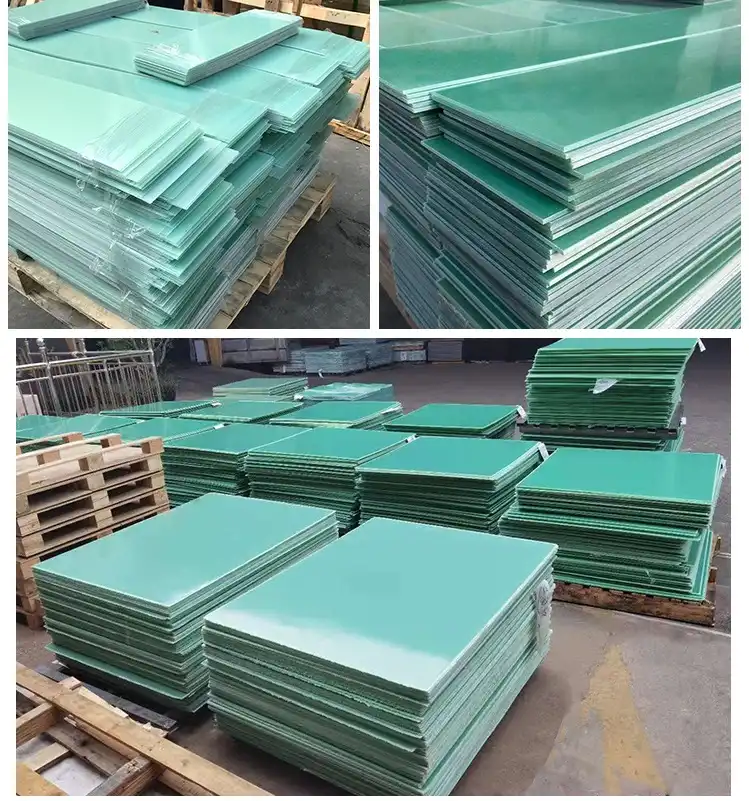

In order to guarantee consistent performance throughout our whole line of FR4 epoxy board solutions, our manufacturing facilities use cutting-edge production technology and quality control systems. We provide clients materials that satisfy legal requirements for industrial, automotive, and electrical applications by closely adhering to international standards such as UL, RoHS, and IPC specifications. Our ability to offer dependable products that support client success in demanding applications is made possible by our mix of manufacturing knowledge and quality procedures.

Product Range and Customization Options

A wide variety of thicknesses, widths, and performance grades are available in our FR4 epoxy board product line, which is intended to satisfy a range of structural application needs. Standard thickness options include thick structural grades larger than 50mm for heavy-duty industrial components and thin sheets appropriate for PCB applications. To satisfy certain application needs, custom thickness standards can be created, offering flexibility for particular design issues.

High-temperature variations, formulas with improved mechanical strength, and materials tailored for CNC machining operations are examples of specialized grades. These choices maximize cost and manufacturing efficiency while allowing clients to choose materials that perfectly match their performance needs. Customers can find the best material requirements for their particular applications with the aid of technical consultation services.

Customer-Centric Services and Partnership Approach

Beyond just providing materials, we also provide extensive support services that increase the value of our collaboration as part of our dedication to customer success. Expert advice on application engineering, material selection, and manufacturing best practices is offered by technical consultancy services. Customers can avoid common difficulties related with thick FR4 applications and optimize their designs with this support.

For clients worldwide, our integrated logistics organization offers a one-stop shop that streamlines the delivery and procurement procedures. This feature lowers the complexity and expenses related to global sourcing while guaranteeing dependable supply chain management. We are able to support customer growth while responding to changing market demands thanks to long-term collaboration ties based on trust and performance excellence.

Conclusion

When correctly chosen and applied in accordance with engineering best practices, FR4 epoxy board exhibits outstanding adaptability for thick structural sections. The material's mechanical strength, thermal stability, and electrical insulating qualities make it useful for demanding applications in the automotive, industrial machinery, electronics, and power generation industries. Design considerations, supplier selection, and production procedures that handle the particular difficulties posed by bigger sections must all be carefully considered for thick FR4 applications to be successful. FR4 may exceed strict performance and safety criteria while offering dependable, affordable solutions for intricate structural needs with the right material selection and engineering support.

FAQs

Can thick FR4 boards maintain structural integrity under high mechanical loads?

Thick FR4 boards demonstrate excellent structural integrity under high mechanical loads when properly designed and manufactured. The material's flexural strength of 415-540 MPa and enhanced compression characteristics in thick sections make it suitable for load-bearing applications. Proper design practices, including appropriate safety factors and stress concentration management, ensure reliable performance in demanding structural roles.

How does FR4 compare to alternatives like phenolic cotton sheets for thick structural applications?

FR4 offers superior electrical insulation properties and better dimensional stability compared to phenolic cotton sheets, making it preferable for applications requiring both structural support and electrical isolation. While phenolic materials may provide slightly better mechanical properties in some configurations, FR4's flame retardancy, thermal performance, and consistent quality make it advantageous for safety-critical applications.

What lead times should procurement teams expect for thick FR4 custom orders?

Lead times for thick FR4 custom orders typically range from 2-4 weeks depending on thickness requirements, quantity, and specification complexity. Thicker sections require extended curing cycles and additional quality verification processes that extend manufacturing time. Working closely with experienced suppliers and maintaining appropriate inventory levels helps manage lead time requirements effectively.

Ready to Source Premium FR4 Epoxy Board for Your Structural Applications?

J&Q stands ready to support your thick structural component requirements with our extensive experience and comprehensive FR4 epoxy board solutions. Our team of technical specialists can help you navigate material selection challenges while ensuring optimal performance for your specific applications. As a trusted FR4 epoxy board manufacturer, we combine manufacturing excellence with responsive customer service to deliver materials that meet your exact specifications and delivery requirements. Contact our experts at info@jhd-material.com to discuss your project requirements and discover how our customized solutions can enhance your product performance while optimizing costs.

References

Institute of Electrical and Electronics Engineers. "Standard for Glass-Epoxy Printed Wiring Board Materials." IEEE Standards Association, 2019.

American Society for Testing and Materials. "Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials." ASTM International, 2020.

International Electrotechnical Commission. "Specifications for Industrial Rigid Laminated Sheets Based on Thermosetting Resins for Electrical Purposes." IEC Standards Publication, 2018.

Society of Automotive Engineers. "Performance Requirements for FR4 Composite Materials in Automotive Applications." SAE International Technical Paper Series, 2021.

National Institute of Standards and Technology. "Thermal and Mechanical Properties of Glass-Reinforced Epoxy Composites." NIST Technical Publication, 2020.

International Association of Electrical Inspectors. "Guidelines for Structural Insulation Materials in Power Distribution Systems." IAEI Safety Standards Manual, 2019.