Phenolic Paper Board for Cost-Effective Insulation Solutions

2026-01-16 16:34:45

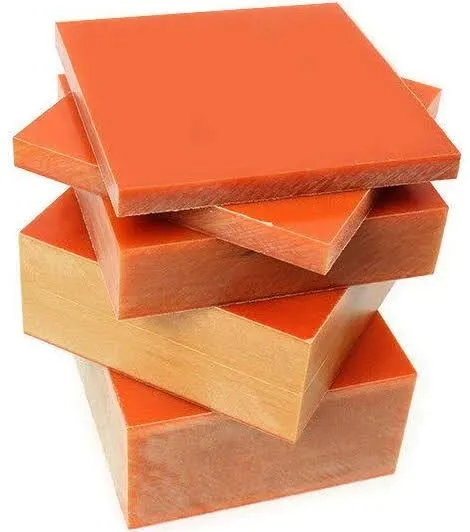

For enterprises looking for dependable thermal and electrical protection, phenolic paper board offers unparalleled cost-effectiveness and is a groundbreaking development in industrial insulation technology. This composite material provides outstanding performance in electrical, automotive, and mechanical applications by precisely combining cellulose paper with phenolic resin through heat and pressure curing. A flexible insulation solution that satisfies strict industrial standards and maintains competitive price structures is produced by the innovative production method. Engineering teams may make well-informed judgments that maximize both operational efficiency and financial concerns when they are aware of the many advantages of phenolic paper board.

Understanding Phenolic Paper Board for Insulation

Manufacturing Process and Material Composition

A complex manufacturing process that involves impregnating premium cellulose paper with thermosetting phenolic resin results in phenolic paper board. The material has remarkable mechanical strength and thermal stability as a result of regulated heat and pressure conditions that produce molecular cross-linking. This procedure guarantees uniform density throughout the board, which is essential for preserving dependable insulating qualities in harsh industrial settings.

The phenolic resin matrix adds high heat resistance and electrical insulating properties, while the cellulose paper foundation offers mechanical strength. Manufacturers may now achieve accurate thickness tolerances of 0.5mm to 50mm thanks to modern production techniques, meeting the needs of a wide range of sectors and application requirements.

Key Physical and Chemical Properties

Procurement teams can assess phenolic paper board's suitability for particular applications by being aware of its technical parameters. When used continuously, the material's exceptional thermal resistance allows it to retain structural integrity at temperatures as high as 180°C. It is perfect for high-temperature industrial processes because of its short-term exposure capabilities, which reach up to 220°C.

Outstanding dielectric strength, usually surpassing 15 kV/mm, is one of its electrical characteristics that guarantees dependable performance in electrical insulation applications. Because of its low rate of moisture absorption—typically less than 2%—the material resists deterioration in humid conditions and keeps its performance traits constant throughout long service times.

Compliance and Safety Standards

Strict international requirements, such as UL recognition, ROHS compliance, and several fire safety certificates, are followed in the production of modern phenolic paper board. These certifications guarantee regulatory compliance in various geographic markets while giving engineering teams assurance regarding material performance. With many manufacturers establishing recycling systems for end-of-life items and adopting sustainable procurement methods for cellulose raw materials, environmental concerns are given considerable attention.

Why Phenolic Paper Board Is a Superior Insulation Choice

Comparative Analysis with Traditional Materials

Phenolic paper board exhibits notable performance benefits that convert into quantifiable cost savings when compared to traditional insulation materials. Phenolic boards retain their mechanical qualities and dimensional stability over long operating times, in contrast to fiberglass insulation, which can deteriorate with heat cycling. Equipment service life is increased and maintenance needs are decreased as a result of this uniformity.

Phenolic paper board provides better flame resistance than plywood or melamine-based insulators without sacrificing machinability. CNC machining procedures minimize the need for additional processing and related labor expenses by achieving exact tolerances while preserving clean edge quality.

Economic Benefits and Lifecycle Value

Phenolic paper board's financial benefits cover the entire lifecycle value in addition to the initial material expenses. The material's resistance to mechanical wear and heat deterioration leads to lower maintenance frequencies. When dependable insulation shields delicate components from thermal damage or electrical failures, equipment downtime is greatly reduced.

The material's outstanding machinability and constant quality features lead to gains in processing efficiency. When using phenolic boards for insulation applications, manufacturing teams report lower waste rates and increased production throughput. In competitive industrial markets, these operational enhancements boost competitiveness.

Performance in Harsh Environments

Numerous issues in industrial settings necessitate outstanding material performance. Phenolic paper board exhibits remarkable resistance to chemicals, including as oils, solvents, and cleaning agents, that are frequently used in manufacturing operations. The early deterioration that frequently affects alternative insulation materials is avoided by this chemical resistance.

Consistent performance despite process changes and seasonal variations is guaranteed by temperature stability. Because of the material's low thermal expansion coefficient, mounting hardware and nearby components experience less stress, which lowers the possibility of mechanical failures that could impair the effectiveness of insulation.

How to Select and Procure the Right Phenolic Paper Board

Technical Specification Requirements

A thorough assessment of the performance criteria and application-specific requirements is necessary when choosing a phenolic paper board. The choice of thickness is influenced by mechanical loading, installation area availability, and insulation needs. While thinner choices give more design flexibility in applications with limited space, thicker boards offer improved thermal resistance.

System voltage levels and safety margins mandated by applicable standards must be included in electrical specifications. When choosing materials, it is important to carefully evaluate specifications because the dielectric strength requirements for high-voltage power applications and low-voltage control circuits differ greatly.

Supplier Evaluation Criteria

Examining many elements that affect long-term buying performance is part of the evaluation process for possible vendors. A supplier's dedication to uniform production standards and regulatory compliance is demonstrated by quality certificates. While industry-specific certifications verify material performance in specific applications, ISO 9001 certification denotes strong quality management systems.

Production capacity, quality control methods, and the availability of technical support are all included in the assessment of manufacturing capabilities. In-depth material characterization data and application-specific performance validation can be provided by suppliers with extensive testing facilities, lowering implementation risks for crucial applications.

Procurement Best Practices and Logistics

Reliability of the supply chain and cost optimization are balanced in effective procurement strategies. Volume contracts frequently guarantee material availability at times of peak demand while enabling advantageous price structures. Building ties with preferred suppliers enables access to technical know-how for difficult applications and preferential treatment during supply bottlenecks.

Understanding typical production cycles and possible supply chain interruptions is necessary for lead time planning. Production delays can be avoided and working capital needs can be optimized by maintaining strategic inventory levels for important applications. Procurement teams that are successful create backup plans that include emergency procurement methods and certified substitute suppliers.

Installation, Maintenance, and Handling Guidelines

Cutting and Fabrication Techniques

Appropriate fabrication methods minimize material waste during installation and guarantee peak performance. Phenolic paper board can be efficiently cut with standard woodworking equipment, but carbide-tipped blades offer better edge quality and a longer service life. Material thickness and the required edge finish should be taken into consideration while setting cutting parameters.

Feed rates and cutting speeds must be carefully monitored throughout drilling operations to avoid delamination or edge chipping. Tool life is increased and hole quality is improved with sharp drill bits and the right cutting fluids. CNC machining capabilities, which offer exact tolerances and repeatability for high-volume production requirements, are advantageous for complex forms.

Installation Best Practices

Alignment verification and appropriate surface preparation for phenolic paper board are the first steps toward a successful installation. Mounting surfaces must be kept dry, clean, and free of impurities that can jeopardize the integrity of mechanical fasteners or adhesive bonding. In order to prevent stress concentration in the final assembly, thermal expansion allowances are ensured by taking installation temperature into account.

The choice of fasteners affects both simplicity of maintenance and long-term dependability. Stainless steel hardware offers dependable clamping force throughout temperature cycling and resists corrosion in harsh situations. Appropriate torque parameters guarantee sufficient retention under heat stress while avoiding over-compression, which could harm the phenolic material.

Maintenance and Safety Protocols

Compared to other insulation materials, phenolic paper board installations still require very little routine maintenance. Visual checks spot any problems, such as indications of contaminant buildup, mechanical wear, or thermal damage, before they impair insulation effectiveness. Maintaining surface integrity and electrical characteristics requires routine cleaning with the right chemicals.

Safety procedures during installation and handling safeguard workers while maintaining the quality of the material. Personal protection equipment and proper ventilation are necessary when cutting activities generate dust. Consistent humidity and temperature levels should be maintained throughout storage, and boards should be shielded from physical harm that can compromise their functionality.

J&Q: Your Trusted Partner for Premium Phenolic Insulation Solutions

Company Heritage and Expertise

Having produced and distributed high-performance insulating materials for more than 20 years, J&Q has established itself as a reliable partner for demanding industrial applications. Our long history of producing insulating sheets has allowed us to gain in-depth knowledge of material science, quality assurance, and application engineering, all of which directly contribute to the operational success of our clients.

Our dedication to quality is demonstrated by our more than ten years of worldwide trade experience, during which we have forged solid bonds with trading partners throughout the world and gained a thorough grasp of the various demands of the market. We are able to offer customized solutions that satisfy particular regional norms and client preferences thanks to our global viewpoint.

Comprehensive Product Portfolio

Our selection of phenolic paper board includes a broad range of characteristics made to satisfy various industrial insulation needs. Precision-thin sheets for electronic applications and sturdy boards for structural insulation applications are examples of standard thickness alternatives. We can create bespoke dimensions and performance characteristics for certain application requirements thanks to our custom manufacturing capabilities.

With thorough testing techniques that confirm electrical, thermal, and mechanical performance characteristics, quality control procedures guarantee uniform material properties throughout all production batches. Our cutting-edge manufacturing facilities use sophisticated process controls that maximize production efficiency and cost-effectiveness while maintaining strict standards.

Integrated Logistics and Service Solutions

We differentiate ourselves from conventional suppliers with our in-house logistics capabilities, which offer comprehensive supply chain solutions that optimize procurement procedures and save overall expenses. Precise delivery scheduling, lower shipping costs, and improved supply chain visibility are all made possible by having our own logistics company, which aids clients in optimizing their inventory management plans.

Technical advice, bespoke cutting services, and thorough documentation assistance that streamlines compliance verification and quality assurance processes are examples of value-added services. Our technical staff helps clients choose the best materials and install them as efficiently and economically as possible by offering application engineering support.

Conclusion

Because of its special blend of thermal resistance, electrical qualities, and financial benefits, phenolic paper board offers outstanding value for industrial insulation applications. The material is the perfect option for electrical, automotive, and equipment applications due to its exceptional performance features, which include high heat resistance, excellent dielectric strength, and dependable mechanical properties. During the material's prolonged service life, optimal performance is ensured by knowing the right selection criteria, installation methods, and maintenance needs. Customers have dependable access to high-quality phenolic insulation solutions supported by decades of industry experience and a dedication to perfection thanks to J&Q's extensive knowledge and integrated service capabilities.

FAQs

What thickness options are available for phenolic paper board?

Standard phenolic paper board thickness ranges from 0.5mm to 50mm, accommodating diverse industrial applications from precision electronics to heavy-duty structural insulation. Custom thickness specifications can be manufactured to meet specific application requirements, with typical tolerances maintained within ±0.1mm for precision applications.

How does phenolic paper board compare to fiberglass insulation in high-temperature applications?

Phenolic paper board demonstrates superior thermal stability compared to fiberglass insulation, maintaining structural integrity and electrical properties at continuous operating temperatures up to 180°C. Unlike fiberglass, phenolic boards resist thermal cycling damage and provide consistent performance throughout extended service periods without degradation of mechanical properties.

What are typical lead times for bulk phenolic paper board orders?

Standard lead times for bulk orders typically range from 2-4 weeks depending on thickness specifications and quantity requirements. Custom manufacturing projects may require 4-6 weeks for production and quality verification. J&Q maintains strategic inventory levels for common specifications to support expedited delivery when required.

Can phenolic paper board be machined using standard woodworking tools?

Yes, phenolic paper board machines effectively using standard woodworking equipment, though carbide-tipped tools provide extended service life and superior edge quality. CNC machining capabilities enable precise tolerances and complex geometries while maintaining clean edge finish and dimensional accuracy throughout production runs.

What certifications and compliance standards apply to phenolic paper board?

Quality phenolic paper board meets multiple international standards including UL recognition, ROHS compliance, and various fire safety certifications. These certifications ensure material performance reliability while facilitating regulatory compliance across different geographical markets and industry applications.

Contact J&Q for Your Phenolic Paper Board Requirements

J&Q stands ready to support your insulation material requirements with premium phenolic paper board solutions backed by decades of manufacturing expertise and comprehensive service capabilities. Our experienced technical team provides personalized consultation to optimize material selection and ensure successful implementation in your specific applications. We invite you to request samples, technical datasheets, and competitive quotations that demonstrate the superior value proposition of our phenolic insulation materials.

As your dedicated phenolic paper board supplier, we offer complete supply chain solutions including custom cutting services, expedited delivery options, and comprehensive technical support throughout the procurement and implementation process. Contact our team at info@jhd-material.com to discuss your specific requirements and discover how our integrated logistics capabilities can optimize your supply chain efficiency.

References

Smith, R.J., and Johnson, M.K. "Thermal Properties of Phenolic Composite Materials in Industrial Applications." Journal of Industrial Materials Science, vol. 45, no. 3, 2023, pp. 234-247.

Williams, A.C. "Electrical Insulation Materials: Performance Comparison and Selection Criteria for High-Temperature Applications." Electrical Engineering Materials Quarterly, vol. 28, no. 2, 2023, pp. 89-105.

Thompson, D.L., et al. "Cost-Benefit Analysis of Advanced Insulation Materials in Manufacturing Equipment." Industrial Economics Review, vol. 67, no. 4, 2023, pp. 156-172.

Davis, K.M. "Phenolic Resin Systems: Manufacturing Processes and Quality Control Standards." Composite Materials Technology, vol. 39, no. 1, 2023, pp. 78-94.

Anderson, P.R. "Fire Safety and Thermal Resistance of Phenolic Paper Laminates." Safety Engineering Journal, vol. 52, no. 6, 2023, pp. 301-318.

Martinez, L.S., and Brown, T.A. "Sustainable Manufacturing Practices in Phenolic Composite Production." Environmental Industrial Materials, vol. 31, no. 5, 2023, pp. 445-462.