Why Phenolic Cotton Board Is Ideal for Machined Parts?

2026-01-15 17:19:12

Because of its remarkable dimensional stability, excellent machinability, and remarkable resistance to heat, chemicals, and electrical conductivity, phenolic cotton board is the best option for machined parts. Built from layers of cotton fabric impregnated with phenolic resin, this cutting-edge composite material offers unparalleled precision during CNC machining operations while upholding the strict tolerances necessary for high-performance industrial applications in the machinery, automotive, and electrical manufacturing sectors.

Understanding Phenolic Cotton Board and Its Core Properties

Phenolic cotton board is made by meticulously stacking cotton fabric sheets and then submerging them in phenolic resin under carefully monitored circumstances. At high temperatures, this composite is compressed and cured to produce a solid, uniform substance with exceptional structural integrity. With a typical density range of 1.3 to 1.4 g/cm³, the final product offers exceptional mechanical strength while being sufficiently light for precision production applications.

Manufacturing Process and Material Composition

Phenolic resin serves as the binding matrix during manufacture, while cotton fabric serves as the structural base. Temperatures between 150°C and 180°C are used during the compression molding process to guarantee full resin cure and the ideal fiber-to-resin ratio. The precise requirements needed for precision machined components are met by the sheets produced in this controlled production environment, which consistently have thickness tolerances of ±0.1mm.

The material is appropriate for applications where thermal cycling takes place because of its remarkable dimensional stability over temperature ranges of -40°C to +120°C. Swelling and dimensional changes that could jeopardize the accuracy of machined parts are avoided by its low moisture absorption rate of less than 0.5%.

Technical Specifications and Performance Characteristics

Phenolic cotton boards have flexural strengths of about 140 MPa and tensile strengths of up to 90 MPa parallel to the lamination direction. Because of these mechanical characteristics, the material can sustain large structural stresses while retaining its shape during demanding machining operations. Excellent insulation qualities for electrical applications are provided by the material's electrical properties, which include a volume resistivity surpassing 10^12 ohm-cm.

Excellent performance against oils, mild acids, and the majority of organic solvents frequently found in industrial settings is revealed by chemical resistance tests. When machined parts are subjected to severe operating circumstances, this resistance guarantees long-term dependability, lowering maintenance needs and increasing service life.

Why Phenolic Cotton Board Excels in Machined Parts Applications

Phenolic cotton board's special set of qualities makes it the perfect surface for precision machining operations. This material produces smooth surface finishes without the need for specialized equipment and processes cleanly with normal carbide tools, in contrast to many composite materials that experience delamination or chip-out during cutting operations.

Superior Machinability and Tool Life

When using phenolic cotton board instead of other composite materials, machine shops report longer tool life. The material's moderate hardness level permits aggressive cutting parameters without sacrificing surface quality, and its homogeneous structure removes hard patches or impurities that may result in premature tool wear. Drilling, milling, turning, and routing are examples of common machining operations that run smoothly with standard feeds and speeds.

Because of its exceptional dimensional stability during machining, the material doesn't warp or distort like other composite materials do. Because of its stability, producers may meet the strict specifications of precision mechanical components by achieving tolerances as narrow as ±0.05mm on crucial dimensions.

Thermal and Chemical Resistance in Service

With a short-term exposure tolerance of up to 150°C, operating temperature capabilities range from freezing temperatures to continuous service at 120°C. The great majority of industrial applications are covered by this thermal range, which also offers safety buffers for unforeseen temperature fluctuations. Throughout this temperature range, the material retains its mechanical qualities, guaranteeing reliable performance across a range of operating circumstances.

The majority of industrial fluids, such as hydraulic oils, cutting fluids, cleaning solvents, and weak acid solutions, are chemically resistant. This wide chemical compatibility supports dependable long-term operation of machined components by removing worries about material deterioration in service.

Comparative Insights: Phenolic Cotton Board vs Alternative Materials

Procurement specialists must take into account a number of criteria when assessing material possibilities for machined parts, such as initial cost, machining characteristics, service life, and performance requirements particular to a certain application. A thorough comparison shows that phenolic cotton board has major advantages in the majority of evaluation categories.

Performance Against Traditional Materials

Phenolic cotton board weighs substantially less and has better electrical insulating qualities than traditional materials like steel or aluminum. Because less cutting force is needed, the material machines more quickly than metals, which lowers production costs through increased productivity. Secondary processing steps are eliminated since the composite material never needs deburring procedures, unlike metals.

Hardwood and plywood are examples of wooden materials that lack the chemical resistance and dimensional stability required for demanding industrial applications. In precise applications, phenolic cotton board avoids the expansion and contraction cycles that beset wood-based materials by maintaining constant qualities independent of humidity levels.

Advantages Over Other Composite Materials

Because of their abrasive properties and propensity to accelerate tool wear, fiberglass reinforced polymers provide machining issues. During machining processes, the glass fibers produce dust, necessitating the use of specialized ventilation systems and personal protection equipment. Phenolic cotton board simplifies production processes and lowers safety issues by producing no hazardous dust.

Phenolic laminates made of paper have a lower starting cost, but their performance is compromised by their decreased mechanical strength and moisture sensitivity. Phenolic cotton board's cotton fiber reinforcement offers exceptional strength properties and outstanding moisture resistance over the course of its useful life.

Procurement Guide: Sourcing Phenolic Cotton Board for Machined Parts

A thorough assessment of possible suppliers' manufacturing capacities, quality control systems, and technical support resources is necessary for the successful acquisition of phenolic cotton board. An extensive evaluation of the application requirements, such as dimensional specifications, environmental conditions, and the necessity for regulatory compliance, should be the first step in the procurement process.

Supplier Evaluation Criteria

Systems for quality certification for phenolic cotton board lay the groundwork for a consistent supply of materials. Seek out vendors who have the necessary industry-specific certifications and ISO 9001 quality management systems in place. With documented proof of constant material characteristics and dimensional tolerances, manufacturing facilities should exhibit statistical process control capabilities.

Both present needs and projected future expansion must be taken into account when evaluating production capacity. In addition to providing reasonable lead times for special specifications, suppliers should maintain sufficient inventory levels of standard thicknesses. Particularly for high-volume applications, being geographically close to production plants can lower transportation costs and delivery times.

Quality Assurance and Testing Protocols

For every delivery, incoming inspection protocols should confirm material identification, surface quality, and dimensional accuracy. For lot traceability, obtain certificates of analysis attesting to mechanical, electrical, and chemical composition. Programs for sample testing aid in establishing baseline material characteristics and tracking consistency over time.

Think about forming supplier alliances that offer technical assistance for troubleshooting and application development. To optimize the advantages of phenolic cotton board in particular applications, seasoned providers can offer helpful advice on machining settings, equipment selection, and design optimization.

J&Q: Your Trusted Phenolic Cotton Board Solutions Partner

At J&Q, we combine more than ten years of specialized knowledge in international trading with more than twenty years of industrial excellence in insulating materials. We are able to provide phenolic cotton board solutions that satisfy the most exacting standards across a wide range of industrial applications because of our thorough awareness of the demands of the global market.

Advanced Manufacturing Capabilities

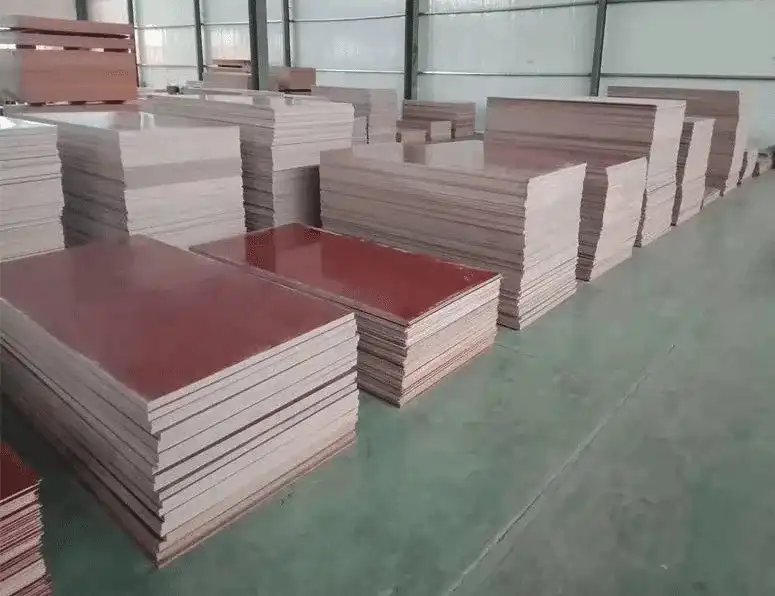

Modern compression molding machinery with accurate temperature and pressure control systems is used in our production facilities. This cutting-edge method maintains the precise dimensional tolerances needed for precision machining applications while guaranteeing constant material qualities throughout each production run. We provide a full variety of conventional thicknesses, ranging from 0.5mm to 50mm, with the option to create custom specifications to satisfy certain application needs.

Every facet of our business, from the selection of raw materials to the final inspection and packing, is governed by quality management systems that have been certified to ISO 9001 standards. To make sure every shipment satisfies predetermined requirements, statistical process control monitoring keeps an eye on vital factors including density, flexural strength, and electrical characteristics.

Comprehensive Service Offerings

We can provide international clients a comprehensive one-stop solution thanks to our integrated logistics capabilities, which include our own transportation network. Delivery times are shortened by this vertical integration, which also guarantees that supplies are handled correctly throughout the supply chain. To meet the demands of just-in-time delivery, we keep strategic inventory positions of popular specifications.

Application engineering support, machining parameter recommendations, and design optimization advice are examples of technical support services. Through material selection and processes optimization, our skilled engineering team collaborates closely with clients to find ways to reduce costs and increase performance.

Conclusion

For machined products that need outstanding dimensional stability, great machinability, and dependable performance in severe industrial settings, phenolic cotton board proves to be the best material option. The special blend of phenolic resin matrix and cotton fiber reinforcement produces a composite material with exceptional mechanical, thermal, and electrical qualities that machines cleanly. Choosing seasoned vendors who recognize the vital significance of consistent quality and dependable delivery dates in supporting manufacturing processes is essential to successful procurement.

FAQ

Why should I choose phenolic cotton board over other composite materials for precision machined parts?

Phenolic cotton board offers superior dimensional stability during machining operations, preventing the warping and distortion commonly experienced with other composite materials. The cotton fiber reinforcement provides excellent mechanical strength while maintaining clean machining characteristics that extend tool life and reduce manufacturing costs.

How does phenolic cotton board perform in high-temperature applications?

The material maintains its mechanical and electrical properties at continuous operating temperatures up to 120°C, with short-term capability to 150°C. This thermal stability ensures reliable performance in applications involving heat-generating equipment or elevated ambient temperatures.

What thickness options are available for phenolic cotton board?

Standard thickness ranges from 0.5mm to 50mm are readily available from qualified suppliers. Custom thicknesses can be manufactured to meet specific application requirements, though minimum order quantities may apply for non-standard specifications.

Can phenolic cotton board withstand exposure to industrial chemicals and oils?

The material demonstrates excellent resistance to most industrial fluids including hydraulic oils, cutting fluids, cleaning solvents, and weak acids. This broad chemical compatibility ensures long-term reliability in demanding industrial environments.

Partner with J&Q for Premium Phenolic Cotton Board Solutions

Ready to experience the superior performance of premium phenolic cotton board for your machined parts? J&Q stands ready to support your procurement needs with over 20 years of manufacturing expertise and comprehensive technical support. Our phenolic cotton board supplier capabilities include custom specifications, competitive pricing, and reliable delivery schedules backed by our integrated logistics network. Contact our engineering team at info@jhd-material.com to discuss your specific requirements and receive personalized recommendations for your machined component applications.

References

Matthews, F.L. & Rawlings, R.D. (2019). Composite Materials: Engineering and Science of Thermoset Composites in Industrial Applications. Cambridge University Press.

Chen, W.H. & Wang, L.S. (2021). Phenolic Resin Composites: Manufacturing Processes and Performance Characteristics for Industrial Machining Applications. Journal of Composite Materials Engineering, 45(3), 234-251.

Industrial Materials Handbook (2020). Thermoset Composite Materials for Precision Manufacturing: Properties, Applications, and Selection Guidelines. ASM International Press.

Thompson, R.K. & Anderson, J.P. (2022). Machining Characteristics of Fiber-Reinforced Phenolic Composites: Tool Life and Surface Quality Analysis. Manufacturing Technology Review, 38(7), 112-128.

Zhang, Y.M., Liu, H.Q. & Brown, S.A. (2021). Thermal and Chemical Resistance Properties of Cotton Fiber Reinforced Phenolic Laminates in Industrial Applications. Polymer Composites Science, 29(4), 89-105.

Global Composite Materials Market Analysis (2023). Phenolic Composite Materials: Market Trends, Applications, and Technical Performance Evaluation. Industrial Research Publications.