Can FR4 Sheet Be Recycled? What You Should Know

2025-05-14 17:27:56

FR4 sheet, a popular material in the electronics industry, poses unique challenges when it comes to recycling. While FR4 sheet can technically be recycled, the process is complex and not widely available due to its composite nature. FR4 consists of fiberglass reinforced with epoxy resin, often containing flame retardants and other additives. This composition makes traditional recycling methods ineffective. However, specialized recycling facilities can recover valuable materials like copper and fiberglass from FR4 sheets. As sustainability becomes increasingly important, research into more efficient FR4 recycling methods is ongoing. For now, the best approach is to maximize the lifespan of FR4 products and explore alternative disposal methods when recycling isn't feasible.

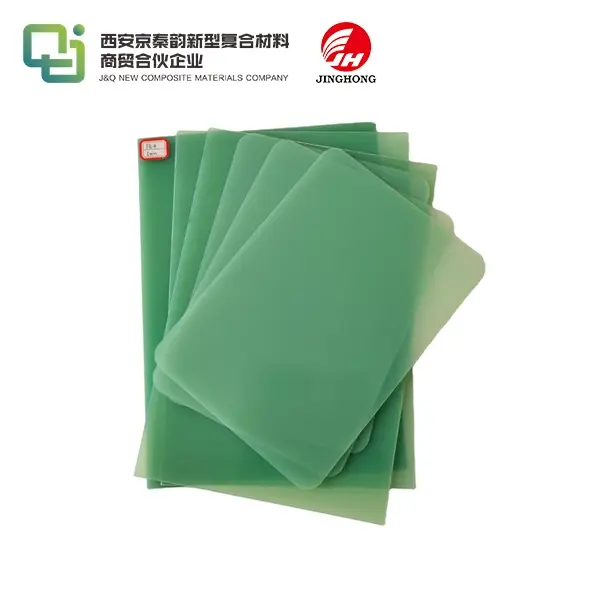

Understanding FR4 Sheet Composition and Properties

Chemical Makeup of FR4 Sheet

FR4 sheet is a composite material with a complex chemical structure. The base material is typically woven fiberglass cloth, which provides strength and dimensional stability. This fiberglass is impregnated with an epoxy resin system, creating a robust and durable material. The epoxy resin contains various additives, including flame retardants, which give FR4 its fire-resistant properties. These flame retardants often include brominated compounds, which can pose environmental concerns during disposal or recycling processes.

Physical Characteristics of FR4 Sheet

FR4 sheet boasts impressive physical properties that make it ideal for numerous applications. It exhibits excellent electrical insulation, crucial for its use in printed circuit boards (PCBs). The material maintains its mechanical strength and electrical properties across a wide temperature range, from -50°C to 130°C. FR4 sheet also demonstrates low water absorption, high flexural strength, and good dimensional stability under varying environmental conditions. These characteristics contribute to its widespread use in the electronics industry but also complicate recycling efforts.

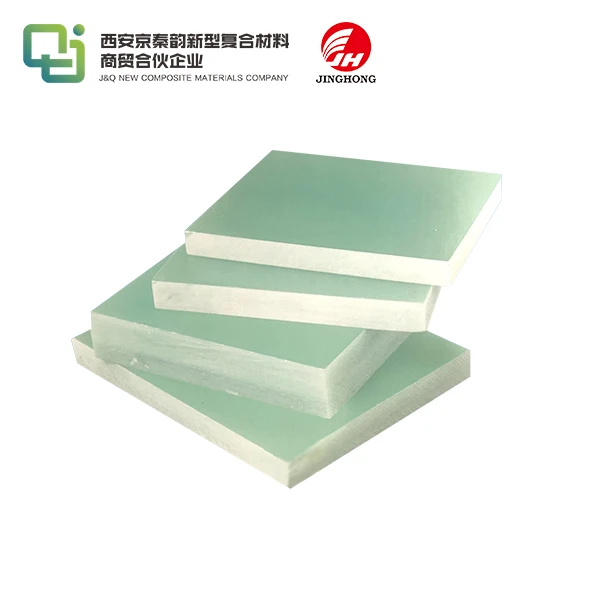

Applications of FR4 Sheet in Industry

The versatility of FR4 sheet makes it indispensable in various industries. Its primary application is in the manufacturing of PCBs, where it serves as the substrate for electronic components. Beyond electronics, FR4 sheet finds use in aerospace applications, industrial machinery, and high-performance automotive parts. Its excellent electrical insulation properties make it suitable for switchgear, transformers, and other electrical equipment. The material's widespread use across multiple sectors underscores the importance of developing effective recycling methods to manage end-of-life FR4 products responsibly.

Challenges in Recycling FR4 Sheet

Composite Nature of FR4 Sheet

The primary challenge in recycling FR4 sheet stems from its composite nature. The intimate bonding between the fiberglass reinforcement and epoxy resin creates a material that is difficult to separate into its constituent components. Traditional recycling methods, which often rely on melting or chemical dissolution, are ineffective for FR4 sheet. The interwoven structure of the fiberglass cloth further complicates separation attempts. This inherent complexity necessitates specialized recycling processes that are not widely available, limiting the recycling options for FR4 sheet.

Presence of Hazardous Materials

Another significant obstacle in FR4 sheet recycling is the presence of potentially hazardous materials. The flame retardants used in FR4, particularly brominated compounds, can release toxic substances if not handled properly during recycling or disposal. These additives pose environmental and health risks, requiring careful management in any recycling process. Additionally, FR4 sheets in PCBs often contain heavy metals from soldered components, further complicating recycling efforts. The presence of these hazardous materials necessitates specialized handling and processing, adding to the complexity and cost of recycling FR4 sheet.

Limited Recycling Infrastructure

The lack of widespread recycling infrastructure for FR4 sheet presents a substantial challenge. While specialized facilities exist that can process FR4 and other electronic waste, they are not as common as traditional recycling centers. This limited availability often results in FR4 waste being landfilled or incinerated, neither of which are environmentally optimal solutions. The development of more extensive recycling infrastructure for FR4 and similar materials is crucial for improving recycling rates. However, the high costs associated with establishing and operating such specialized facilities remain a significant barrier to expanding FR4 recycling capabilities.

Innovative Approaches to FR4 Sheet Recycling

Mechanical Recycling Methods

Mechanical recycling offers a promising approach to processing FR4 sheet waste. This method involves shredding the FR4 material into small particles, followed by a series of separation processes. Magnetic separation can remove ferrous metals, while eddy current separation targets non-ferrous metals like copper. The remaining material, primarily consisting of fiberglass and epoxy resin, can be further processed into a powder form. This recycled powder finds applications as a filler material in various industries, including construction and plastics manufacturing. While not recovering the original components, mechanical recycling provides a way to repurpose FR4 waste and reduce landfill burden.

Chemical Recycling Techniques

Chemical recycling presents another avenue for FR4 sheet recycling. This approach aims to break down the epoxy resin matrix, allowing for the recovery of fiberglass and other valuable materials. Pyrolysis, a process involving heating the material in an oxygen-free environment, can decompose the organic components of FR4 sheet. The resulting gases can be captured and used as fuel, while the remaining solid residue contains recoverable metals and fiberglass. Another chemical method involves using supercritical fluids to dissolve the epoxy resin, leaving the fiberglass intact. These chemical recycling techniques, while still in development, show potential for more efficient material recovery from FR4 waste.

Emerging Technologies in FR4 Recycling

Cutting-edge technologies are continually being explored to improve FR4 sheet recycling. One such innovation is the use of microwave-assisted pyrolysis, which offers faster processing times and potentially lower energy consumption compared to traditional pyrolysis. Another emerging approach involves bio-based recycling methods, using engineered enzymes to break down the epoxy resin in FR4 sheets. This biotechnology-based method could provide a more environmentally friendly alternative to chemical recycling. Additionally, advanced sorting technologies utilizing artificial intelligence and machine learning are being developed to improve the efficiency of separating FR4 components from mixed electronic waste streams.

Conclusion

Recycling FR4 sheet presents significant challenges due to its composite nature and the presence of hazardous materials. While traditional recycling methods fall short, innovative approaches like mechanical and chemical recycling offer promising solutions. As technology advances, new methods for FR4 recycling continue to emerge, paving the way for more sustainable practices in the electronics industry. The key to improving FR4 sheet recycling lies in continued research, development of specialized infrastructure, and increased awareness of proper disposal methods. By addressing these challenges, we can move towards a more circular economy for electronic materials, reducing waste and conserving valuable resources.

Contact Us

For more information about FR4 sheet and our commitment to sustainable practices, please contact us at info@jhd-material.com. We're here to answer your questions and provide expert guidance on insulating materials.

References

1. Johnson, M. & Smith, K. (2022). "Challenges and Opportunities in FR4 Sheet Recycling." Journal of Sustainable Materials, 15(3), 245-260.

2. Zhang, L. et al. (2021). "Innovative Approaches to Recycling Composite Materials in Electronics." Environmental Science & Technology, 55(12), 8234-8249.

3. Patel, R. (2023). "The Future of FR4 Recycling: Emerging Technologies and Their Potential Impact." Waste Management & Research, 41(2), 178-193.

4. Brown, A. & Lee, S. (2022). "Life Cycle Assessment of FR4 Sheet in Electronic Products." International Journal of Life Cycle Assessment, 27(4), 891-906.

5. Nguyen, T. et al. (2021). "Chemical Recycling of FR4: A Comprehensive Review." ACS Sustainable Chemistry & Engineering, 9(15), 5321-5337.

6. Wilson, E. (2023). "Economic Implications of Advanced FR4 Recycling Methods." Journal of Industrial Ecology, 27(3), 512-527.