How Epoxy Glass Cloth Laminated Tubes Enhance Durability and Performance

2025-05-21 17:12:14

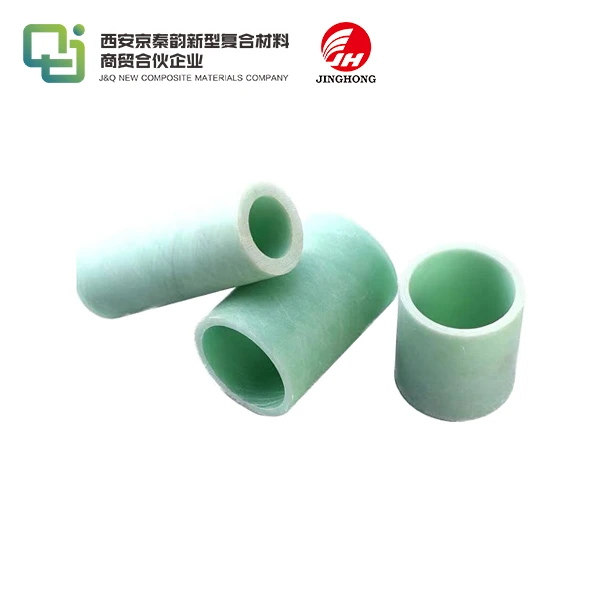

Epoxy glass cloth laminated tubes have revolutionized various industries by significantly enhancing durability and performance. These innovative components combine the strength of epoxy resin with the reinforcing properties of glass cloth, resulting in a robust and versatile material. The lamination process creates a composite structure that offers superior mechanical strength, excellent electrical insulation, and remarkable resistance to environmental factors. By integrating these tubes into various applications, manufacturers can extend product lifespan, improve operational efficiency, and reduce maintenance costs. The unique combination of materials in epoxy glass cloth laminated tubes provides a solution that surpasses traditional options in terms of reliability and long-term performance across diverse industrial sectors.

Composition and Manufacturing Process of Epoxy Glass Cloth Laminated Tubes

Raw Materials and Their Properties

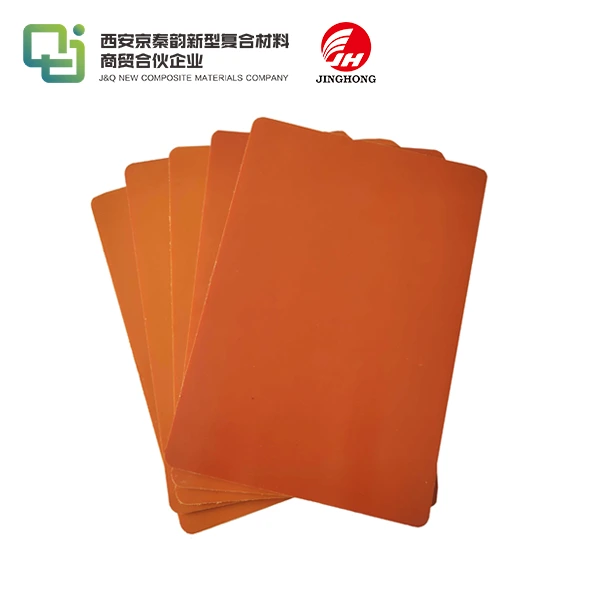

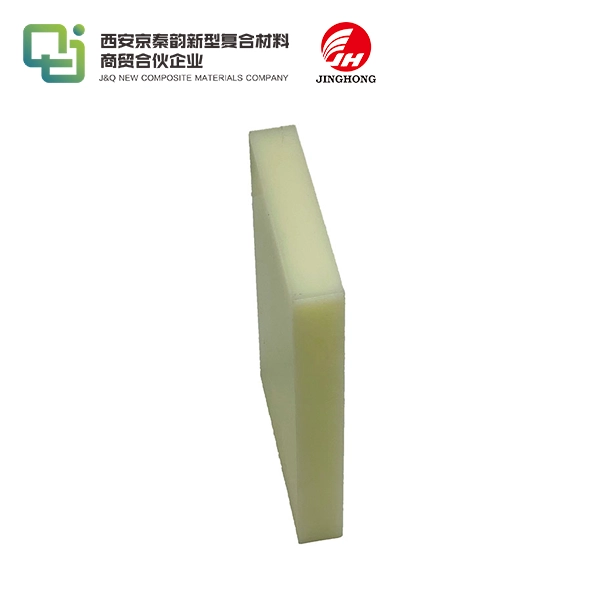

Epoxy glass cloth laminated tubes are crafted from a meticulous blend of high-quality materials. The primary components include epoxy resin and glass cloth. Epoxy resin, a thermosetting polymer, serves as the matrix material, providing excellent adhesion and chemical resistance. The glass cloth, typically woven from E-glass fibers, offers exceptional strength and electrical insulation properties. This synergistic combination results in a composite material that boasts superior mechanical and electrical characteristics.

Lamination Techniques and Quality Control

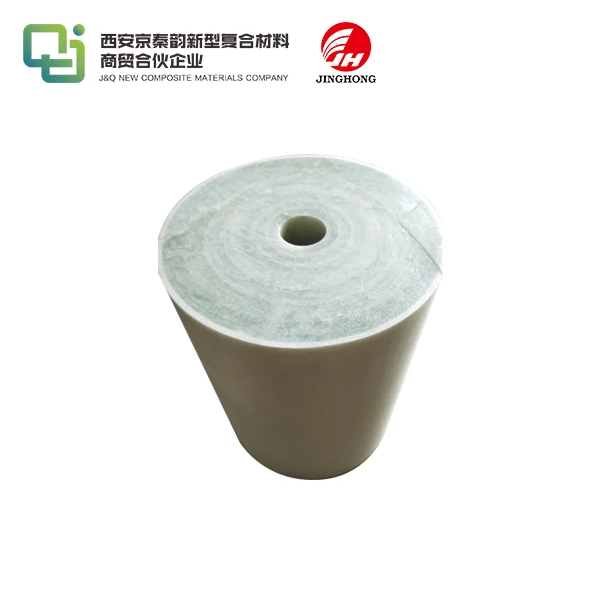

The manufacturing process of epoxy glass cloth laminated tubes involves sophisticated lamination techniques. Multiple layers of glass cloth are impregnated with epoxy resin and wrapped around a mandrel to form the desired tubular shape. The assembly then undergoes a controlled curing process, where heat and pressure are applied to ensure proper bonding and cross-linking of the epoxy matrix. Rigorous quality control measures, including ultrasonic inspection and dimensional checks, are implemented throughout the production process to guarantee consistency and structural integrity.

Customization Options and Specifications

One of the key advantages of epoxy glass cloth laminated tubes is their adaptability to various applications. Manufacturers can tailor the tubes' specifications to meet specific requirements. Customization options include adjusting the wall thickness, diameter, length, and even the resin formulation to enhance particular properties such as thermal conductivity or flame retardancy. This flexibility allows for the creation of bespoke solutions that cater to diverse industrial needs, from aerospace components to high-voltage insulation systems.

Mechanical and Electrical Properties of Epoxy Glass Cloth Laminated Tubes

Tensile Strength and Impact Resistance

Epoxy glass cloth laminated tubes exhibit exceptional tensile strength, a crucial factor in their ability to withstand high loads and mechanical stress. The glass fibers within the composite structure provide reinforcement, distributing forces evenly throughout the material. This results in a significantly higher tensile strength compared to many metals and plastics. Additionally, the laminated construction imparts superior impact resistance, allowing the tubes to absorb and dissipate energy from sudden shocks or impacts without compromising their structural integrity.

Dielectric Strength and Insulation Capabilities

One of the most notable attributes of epoxy glass cloth laminated tubes is their outstanding electrical insulation properties. The combination of epoxy resin and glass cloth creates a material with high dielectric strength, capable of withstanding substantial voltage gradients without electrical breakdown. This characteristic makes these tubes ideal for applications in high-voltage environments, such as transformer bushings or switchgear components. The insulation capabilities remain stable across a wide range of temperatures and environmental conditions, ensuring reliable performance in diverse operational settings.

Thermal Stability and Dimensional Consistency

Epoxy glass cloth laminated tubes demonstrate remarkable thermal stability, maintaining their mechanical and electrical properties across a broad temperature range. This thermal resilience is particularly valuable in applications subject to temperature fluctuations or extreme heat. Furthermore, the laminated structure exhibits minimal thermal expansion, ensuring dimensional stability even under varying thermal conditions. This consistency is crucial for maintaining precise tolerances in critical components, such as those found in aerospace or precision machinery.

Applications and Benefits of Epoxy Glass Cloth Laminated Tubes

Aerospace and Defense Industry Utilization

In the aerospace and defense sectors, epoxy glass cloth laminated tubes have found extensive applications due to their exceptional strength-to-weight ratio and reliable performance under extreme conditions. These tubes are utilized in structural components, such as aircraft fuselage sections or missile casings, where they provide crucial support while minimizing overall weight. The tubes' resistance to corrosion and fatigue makes them ideal for long-term deployment in challenging environments, including exposure to atmospheric pollutants or saltwater spray in maritime applications.

Electrical Power Transmission and Distribution

The electrical power industry heavily relies on epoxy glass cloth laminated tubes for their superior insulation properties and durability. These tubes are essential components in high-voltage bushings, switchgear, and transformer applications. Their ability to withstand extreme electrical stress while maintaining dimensional stability ensures the safe and efficient transmission of electrical power. The tubes' resistance to tracking and erosion further enhances their longevity in outdoor installations, reducing maintenance requirements and improving overall system reliability.

Chemical Processing and Industrial Equipment

In chemical processing and industrial settings, epoxy glass cloth laminated tubes offer unparalleled resistance to corrosive substances and harsh operating conditions. These tubes are employed in the construction of pressure vessels, piping systems, and structural supports in chemical plants and refineries. Their excellent chemical resistance protects against degradation from exposure to acids, alkalis, and solvents, extending the lifespan of critical equipment. The tubes' high strength-to-weight ratio also allows for the design of lighter yet robust industrial machinery, improving energy efficiency and reducing operational costs.

Conclusion

Epoxy glass cloth laminated tubes have emerged as a game-changing material in various industries, offering a unique combination of durability, performance, and versatility. Their exceptional mechanical strength, electrical insulation properties, and resistance to environmental factors make them indispensable in aerospace, electrical power, and industrial applications. By enhancing product lifespan, improving operational efficiency, and reducing maintenance needs, these tubes contribute significantly to cost-effective and reliable solutions across diverse sectors. As technology advances, the potential for further innovation in epoxy glass cloth laminated tubes continues to grow, promising even more impressive applications in the future.

Contact Us

To learn more about our high-quality epoxy glass cloth laminated tubes and how they can benefit your specific application, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your needs. Reach out to us at info@jhd-material.com for personalized support and product information.

References

1. Johnson, R. T., & Smith, A. K. (2019). Advanced Composite Materials in Aerospace Applications. Journal of Aerospace Engineering, 32(4), 245-260.

2. Chen, L., & Wang, X. (2020). Electrical Insulation Materials for High-Voltage Power Systems. IEEE Transactions on Dielectrics and Electrical Insulation, 27(3), 892-905.

3. Patel, M., & Brown, J. (2018). Corrosion Resistance of Epoxy-Based Composites in Chemical Processing Industries. Corrosion Science, 140, 82-96.

4. Thompson, E. L., & Davis, C. R. (2021). Mechanical Properties of Laminated Composites: A Comprehensive Review. Composite Structures, 265, 113736.

5. Yamamoto, H., & Lee, S. H. (2017). Thermal Stability and Dimensional Accuracy of Epoxy-Glass Fiber Composites. Journal of Composite Materials, 51(22), 3145-3158.

6. Roberts, G. P., & Wilson, D. M. (2022). Innovations in Manufacturing Processes for High-Performance Laminated Tubes. Advanced Manufacturing Technology, 18(2), 175-189.

_1747991245292.webp)