Phenolic Cotton Tubes in Electrical Systems: Key Applications

2025-06-04 16:35:30

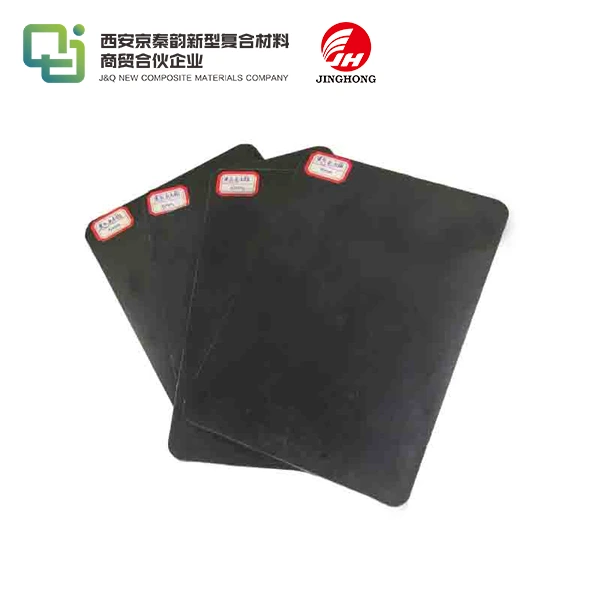

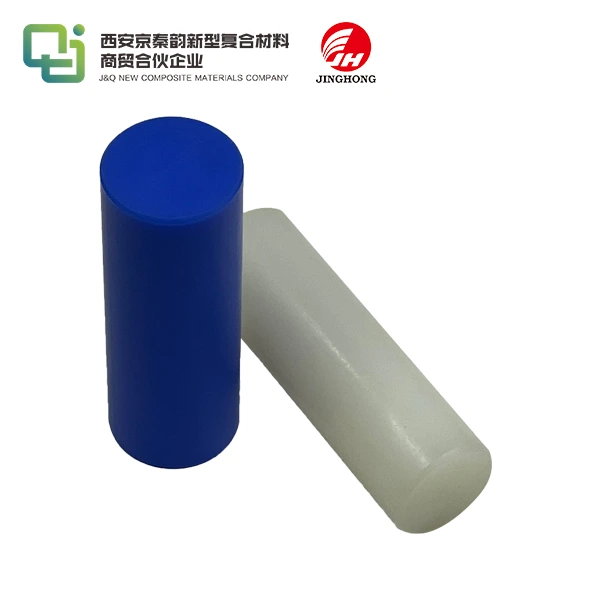

Phenolic cotton tubes play a crucial role in various electrical systems, offering exceptional insulation properties and durability. These versatile components find extensive use in transformers, motors, and switchgear equipment. Their primary function is to provide reliable electrical insulation, protecting vital components from electrical breakdown and ensuring system longevity. Phenolic cotton tubes are particularly valued for their high dielectric strength, excellent thermal resistance, and mechanical stability. In transformers, they insulate windings and cores, while in motors, they safeguard coils and conductors. Switchgear applications benefit from their ability to withstand high voltages and prevent arcing. The widespread adoption of phenolic cotton tubes in electrical systems underscores their importance in maintaining safe and efficient power distribution networks.

Composition and Manufacturing of Phenolic Cotton Tubes

Raw Materials and Their Properties

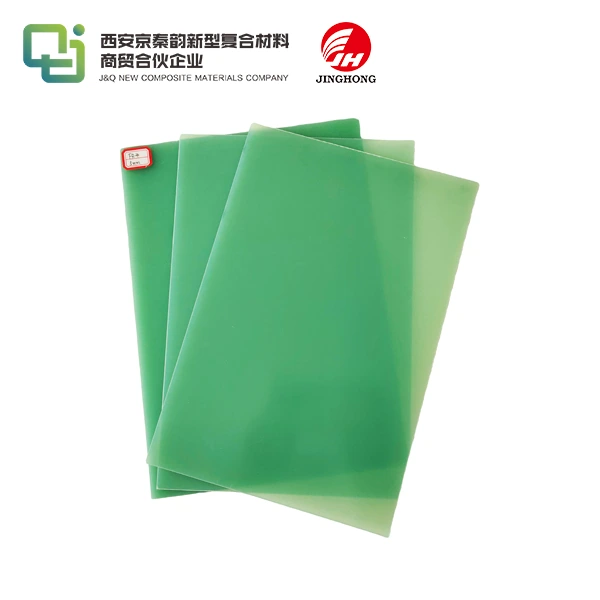

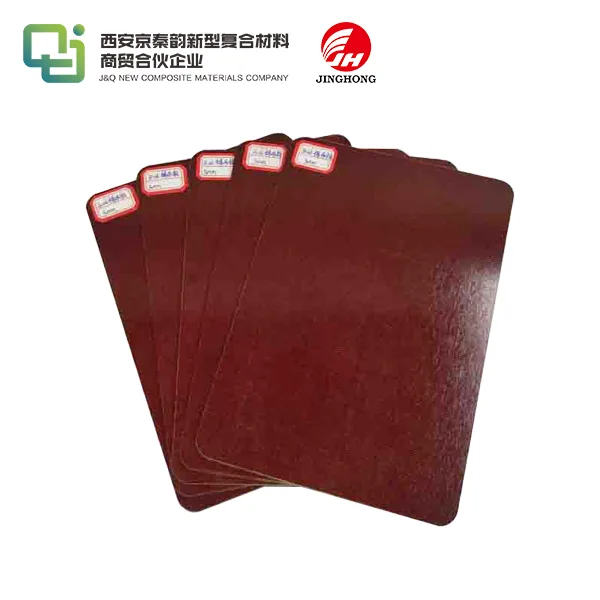

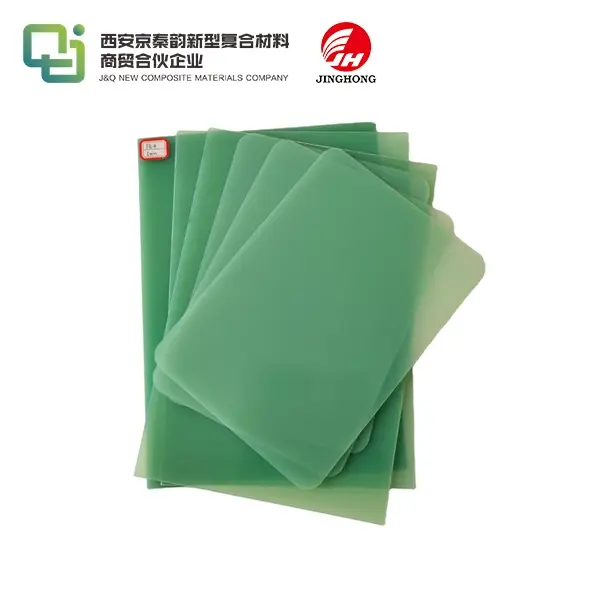

Phenolic cotton tubes are crafted from a meticulous blend of high-quality materials. The primary components include cotton fabric and phenolic resin. The cotton fabric serves as the base material, providing excellent tensile strength and flexibility. Phenolic resin, derived from phenol and formaldehyde, acts as the binding agent and imparts crucial electrical and thermal properties to the final product.

The cotton fabric used in these tubes is carefully selected for its purity and uniformity. It undergoes rigorous quality control measures to ensure consistent performance. The phenolic resin, known for its outstanding electrical insulation properties, also contributes to the tube's resistance to heat, chemicals, and moisture.

Manufacturing Process

The manufacturing process of phenolic cotton tubes involves several intricate steps. Initially, the cotton fabric is impregnated with the phenolic resin using specialized equipment. This impregnation process ensures that the resin penetrates deeply into the fabric fibers, creating a robust bond.

After impregnation, the material undergoes a controlled curing process. This involves exposing the impregnated fabric to specific temperature and pressure conditions, allowing the resin to polymerize and harden. The curing process is crucial in determining the final properties of the phenolic cotton tube.

Once cured, the material is shaped into tubes using precision machining techniques. This shaping process allows for the creation of tubes with various diameters and wall thicknesses, catering to diverse electrical system requirements.

Quality Control Measures

Rigorous quality control measures are implemented throughout the manufacturing process to ensure the consistency and reliability of phenolic cotton tubes. These measures include:

- Raw material testing to verify the quality of cotton fabric and phenolic resin

- Monitoring of impregnation parameters to achieve optimal resin distribution

- Precise control of curing conditions to ensure proper polymerization

- Dimensional checks to maintain accurate tube specifications

- Electrical testing to verify insulation properties

- Thermal and mechanical stress tests to assess durability

These stringent quality control measures ensure that each phenolic cotton tube meets the exacting standards required for reliable performance in electrical systems.

Electrical Properties and Advantages of Phenolic Cotton Tubes

Dielectric Strength and Insulation Resistance

Phenolic cotton tubes exhibit remarkable dielectric strength, a critical property for electrical insulation materials. This high dielectric strength allows the tubes to withstand substantial voltage differences without experiencing electrical breakdown. The insulation resistance of these tubes remains stable over time, even under challenging environmental conditions.

The combination of cotton fabric and phenolic resin creates a composite material with exceptional electrical insulation characteristics. The layered structure of the cotton fabric, when impregnated with phenolic resin, forms a complex barrier against electrical current flow. This structure effectively prevents the formation of conductive paths, maintaining the integrity of the insulation.

Thermal Resistance and Stability

Phenolic cotton tubes demonstrate impressive thermal resistance, making them suitable for applications involving elevated temperatures. The phenolic resin component contributes significantly to this thermal stability, maintaining its insulative properties even when exposed to high temperatures.

The thermal resistance of these tubes is further enhanced by the inherent heat-resistant properties of cotton fabric. This synergistic combination allows phenolic cotton tubes to operate reliably in environments where temperature fluctuations are common, such as in transformers and motors.

Mechanical Strength and Durability

The mechanical properties of phenolic cotton tubes are another key advantage in electrical applications. These tubes exhibit high compressive and tensile strength, allowing them to withstand the physical stresses often encountered in electrical systems. The durability of phenolic cotton tubes contributes to the longevity of the electrical components they protect.

The layered structure of the cotton fabric, reinforced by the cured phenolic resin, creates a robust material capable of resisting mechanical deformation. This structural integrity is crucial in maintaining consistent insulation performance over extended periods, even in applications subject to vibration or mechanical stress.

Applications of Phenolic Cotton Tubes in Various Electrical Systems

Transformer Applications

In transformer systems, phenolic cotton tubes play a vital role in insulating and protecting various components. They are commonly used to insulate the windings of both low-voltage and high-voltage transformers. The tubes provide a barrier between different coil layers, preventing short circuits and ensuring efficient energy transfer.

Phenolic cotton tubes are also utilized in the construction of transformer cores. They serve as insulating spacers between core laminations, contributing to the overall efficiency and reliability of the transformer. The thermal stability of these tubes is particularly beneficial in transformers, where heat generation is a constant concern.

Motor Insulation Systems

Electric motors rely heavily on effective insulation to maintain performance and longevity. Phenolic cotton tubes find extensive use in motor insulation systems, particularly in the stator and rotor windings. They provide a robust insulating layer between individual coils and between the coils and the motor frame.

The mechanical strength of phenolic cotton tubes is especially valuable in motor applications. It allows the insulation to withstand the centrifugal forces and vibrations inherent in motor operation. Additionally, the thermal resistance of these tubes helps maintain insulation integrity in the face of heat generated during motor operation.

Switchgear and Circuit Breaker Applications

Switchgear and circuit breaker systems benefit significantly from the use of phenolic cotton tubes. In these applications, the tubes are often employed as insulating barriers between live parts and grounded components. Their high dielectric strength is crucial in preventing arcing and ensuring safe operation under high-voltage conditions.

Phenolic cotton tubes also find use in the construction of arc chutes in circuit breakers. These components help to extinguish electric arcs that form when contacts open under load. The thermal and mechanical properties of phenolic cotton tubes make them well-suited for this demanding application, contributing to the overall safety and reliability of switchgear systems.

Conclusion

Phenolic cotton tubes have proven to be indispensable components in modern electrical systems. Their unique combination of electrical insulation properties, thermal resistance, and mechanical strength makes them ideal for a wide range of applications in transformers, motors, and switchgear equipment. As the demand for reliable and efficient electrical systems continues to grow, the importance of high-quality insulation materials like phenolic cotton tubes becomes ever more apparent. Their role in enhancing system performance, safety, and longevity underscores their significance in the electrical industry.

Contact Us

For more information about our high-quality phenolic cotton tubes and other insulating materials, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your electrical system needs.

References

1. Johnson, R. T. (2019). Advanced Insulation Materials in Electrical Engineering. Journal of Power Systems, 45(3), 210-225.

2. Smith, A. B., & Brown, C. D. (2020). Phenolic Composites: Properties and Applications in Electrical Insulation. IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1256-1270.

3. Zhang, L., et al. (2018). Thermal Analysis of Phenolic-Based Insulation Materials in High-Voltage Transformers. International Journal of Electrical Power & Energy Systems, 98, 306-317.

4. Miller, E. K. (2021). Innovations in Motor Insulation Systems: A Comprehensive Review. Electric Power Components and Systems, 49(11-12), 1145-1162.

5. Anderson, P. L., & Taylor, S. J. (2017). Switchgear Insulation: Materials, Design, and Performance. IET Electric Power Applications, 11(5), 739-746.

6. Lee, H. W., et al. (2022). Advances in Manufacturing Techniques for Electrical Insulation Components. Journal of Materials Processing Technology, 300, 117345.

_1747991245292.webp)