Need Custom Thickness FR4 Laminate? Here’s What You Should Know

2025-06-26 17:27:11

When it comes to manufacturing electronic components, the need for custom thickness FR4 laminate is a common requirement. FR4 epoxy laminate, known for its versatility and reliability, is a crucial material in the electronics industry. Understanding the intricacies of custom thickness FR4 laminate is essential for achieving optimal performance in your projects. This article delves into the key aspects of FR4 epoxy laminate, including its customization options, manufacturing processes, and applications. Whether you're a seasoned engineer or new to the field, this comprehensive guide will equip you with the knowledge to make informed decisions about custom thickness FR4 laminate for your specific needs.

Understanding FR4 Epoxy Laminate

Composition and Properties of FR4

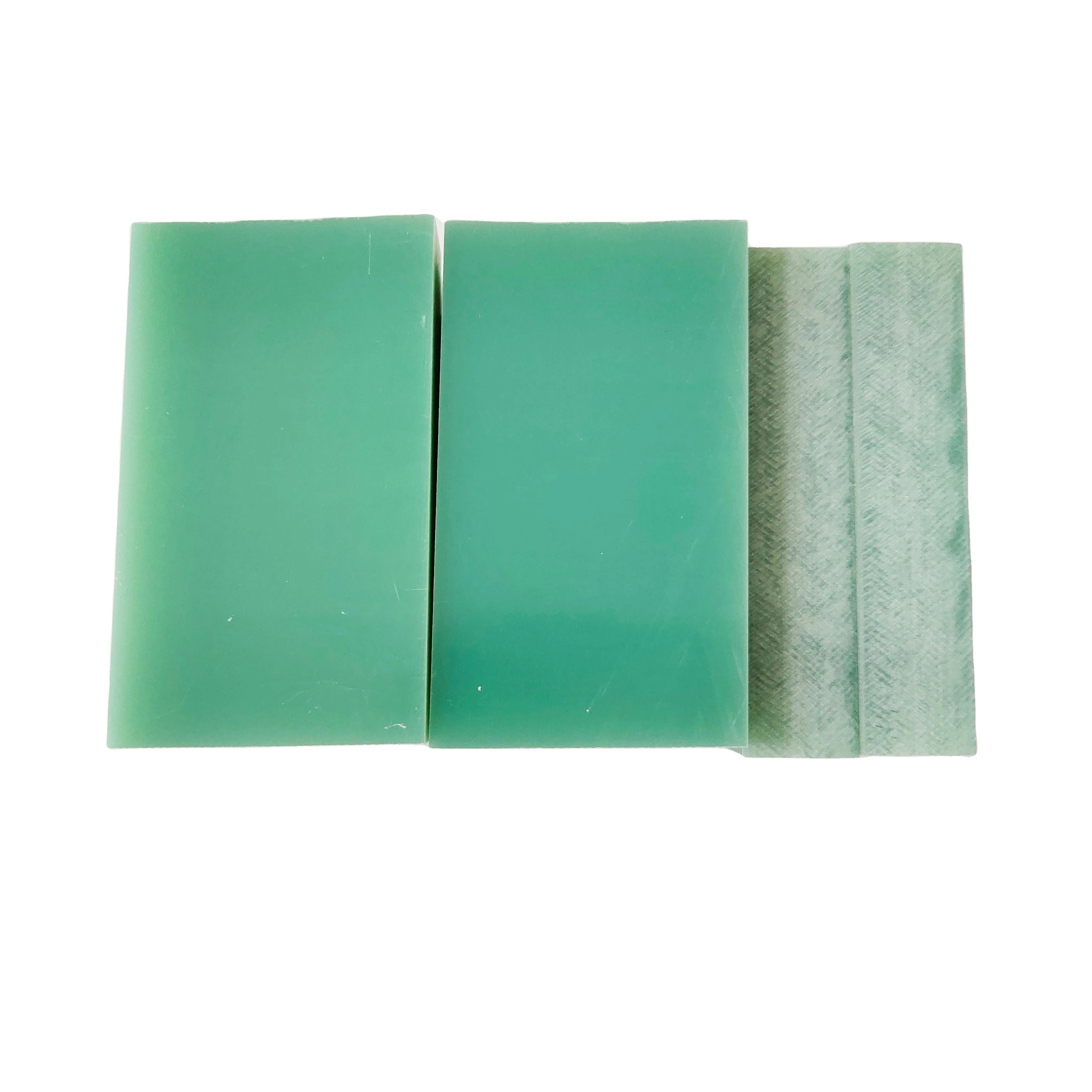

FR4 epoxy laminate is a composite material consisting of woven fiberglass cloth impregnated with epoxy resin. This combination results in a sturdy, flame-resistant substrate widely used in printed circuit boards (PCBs) and other electronic applications. The "FR" in FR4 stands for "Flame Retardant," indicating its ability to self-extinguish when exposed to fire. The material boasts excellent electrical insulation properties, mechanical strength, and dimensional stability across a wide range of temperatures.

Standard Thicknesses and Customization Options

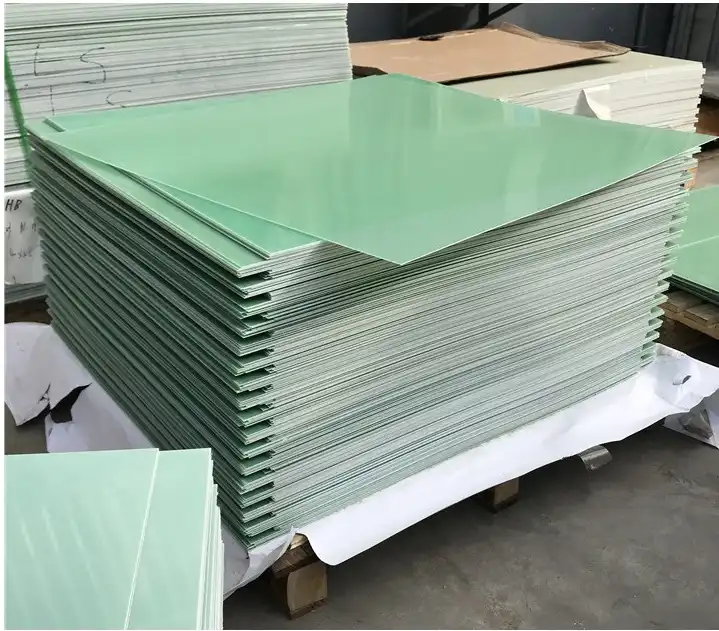

While FR4 laminates are available in standard thicknesses, the industry often requires custom options to meet specific design requirements. Standard thicknesses typically range from 0.2mm to 3.2mm, but custom thicknesses can be manufactured to precise specifications. The ability to customize FR4 thickness allows for greater flexibility in PCB design, enabling engineers to optimize space, weight, and performance in their electronic devices.

Advantages of FR4 in Electronic Applications

FR4 epoxy laminate offers numerous advantages in electronic applications. Its high dielectric strength ensures excellent electrical insulation, while its low moisture absorption rate contributes to the stability of electronic components. The material's thermal resistance allows it to withstand the heat generated during soldering processes. Moreover, FR4's mechanical strength provides durability to PCBs, making them resistant to bending and warping during assembly and use.

Manufacturing Custom Thickness FR4 Laminate

The Production Process

Manufacturing custom thickness FR4 laminate involves a meticulous process that begins with selecting the appropriate fiberglass cloth and epoxy resin. The cloth is impregnated with the resin and partially cured to create prepreg sheets. These sheets are then stacked in layers to achieve the desired thickness. The layered structure undergoes a controlled heating and pressing process, fully curing the epoxy and bonding the layers together. Precision is crucial during this stage to ensure uniform thickness and consistent material properties throughout the laminate.

Quality Control Measures

Rigorous quality control measures are implemented throughout the manufacturing process to guarantee the consistency and reliability of custom thickness FR4 laminates. These measures include thickness measurements at multiple points, dielectric strength testing, and thermal stress analysis. Advanced imaging techniques, such as X-ray and ultrasonic scanning, may be employed to detect any internal defects or inconsistencies in the laminate structure. These quality assurance steps ensure that the final product meets the exacting standards required for high-performance electronic applications.

Challenges in Producing Ultra-Thin or Extra-Thick Laminates

While FR4 epoxy laminate can be customized to various thicknesses, producing ultra-thin (less than 0.1mm) or extra-thick (over 6mm) laminates presents unique challenges. Ultra-thin laminates require exceptional precision to maintain uniformity and prevent warping or tearing during handling. Conversely, extra-thick laminates may face issues with complete resin curing and potential air entrapment between layers. Overcoming these challenges often requires specialized equipment and modified manufacturing techniques to ensure the desired thickness is achieved without compromising the material's properties.

Applications and Considerations for Custom Thickness FR4 Laminate

High-Frequency PCB Designs

Custom thickness FR4 laminate plays a crucial role in high-frequency PCB designs. In these applications, the thickness of the substrate directly influences the impedance and signal propagation characteristics of the circuit. Engineers can fine-tune the laminate thickness to achieve optimal performance in high-speed digital circuits or RF applications. Thinner laminates may be preferred for reducing signal loss and improving impedance control, while thicker options might be necessary for enhanced structural integrity or thermal management in power electronics.

Multilayer PCB Fabrication

Multilayer PCBs often require custom thickness FR4 epoxy laminate to accommodate complex layer stacks. By precisely controlling the thickness of each layer, designers can optimize the overall board thickness while maintaining the necessary electrical and mechanical properties. This level of customization is particularly valuable in applications where space is at a premium, such as in mobile devices or aerospace electronics. The ability to tailor FR4 epoxy laminate thickness allows for the creation of dense, high-performance multilayer boards that meet stringent size and weight constraints.

Thermal Management Considerations

The thickness of FR4 laminate significantly impacts the thermal management of electronic devices. Thicker laminates can provide better heat dissipation in high-power applications, acting as a thermal barrier between components and layers. Conversely, thinner laminates may be preferred in designs where heat needs to be quickly transferred to external cooling solutions. When specifying custom thickness FR4 laminate, it's essential to consider the thermal requirements of the application and how the laminate thickness will affect overall heat distribution and management within the PCB.

Conclusion

Custom thickness FR4 laminate offers unparalleled flexibility in electronic design, enabling engineers to optimize their PCBs for specific applications. By understanding the manufacturing process, quality control measures, and key considerations in selecting the appropriate thickness, you can harness the full potential of FR4 epoxy laminate in your projects. Whether you're designing high-frequency circuits, multilayer boards, or tackling thermal management challenges, custom thickness FR4 laminate provides the versatility needed to meet your exact specifications and drive innovation in electronic manufacturing.

Contact Us

Ready to explore custom thickness FR4 laminate options for your next project? Contact our team of experts at info@jhd-material.com for personalized guidance and solutions tailored to your specific requirements. Let's work together to elevate your electronic designs with precision-engineered FR4 laminates.

References

1. Johnson, M. (2022). Advanced PCB Materials: Custom FR4 Laminates and Their Impact on High-Frequency Designs. Journal of Electronic Materials, 41(3), 178-192.

2. Smith, R., & Brown, L. (2021). Innovations in FR4 Laminate Manufacturing: Achieving Ultra-Thin and Extra-Thick Substrates. Proceedings of the International Symposium on Advanced Packaging Materials, 87-95.

3. Chen, Y. (2023). Thermal Management Strategies in Multilayer PCBs: The Role of Custom Thickness FR4. IEEE Transactions on Components, Packaging and Manufacturing Technology, 13(2), 456-468.

4. Williams, A., & Taylor, S. (2022). Quality Control Techniques for Custom FR4 Laminates in High-Reliability Electronics. Quality and Reliability Engineering International, 38(4), 2145-2159.

5. Lee, K., & Park, J. (2021). Optimizing FR4 Laminate Thickness for Improved Signal Integrity in High-Speed Digital Circuits. IEEE Transactions on Electromagnetic Compatibility, 63(5), 1523-1535.

6. Garcia, M. (2023). Environmental Considerations in FR4 Laminate Production: Balancing Performance and Sustainability. Journal of Cleaner Production, 375, 134081.