Epoxy Sheets Explained: Strength, Use Cases, and Value

2025-06-27 15:51:57

Epoxy sheets are versatile, high-performance materials that have revolutionized various industries due to their exceptional strength, durability, and versatility. These composite materials, formed by curing epoxy resin with hardeners, offer a unique combination of mechanical, electrical, and chemical properties. From aerospace and electronics to construction and automotive sectors, epoxy sheets have found numerous applications. Their ability to withstand extreme temperatures, resist chemicals, and provide excellent electrical insulation makes them invaluable in countless products and structures. This article delves into the strength, diverse use cases, and inherent value of epoxy sheets, showcasing why they've become indispensable in modern manufacturing and engineering.

The Remarkable Strength of Epoxy Sheets

Mechanical Properties

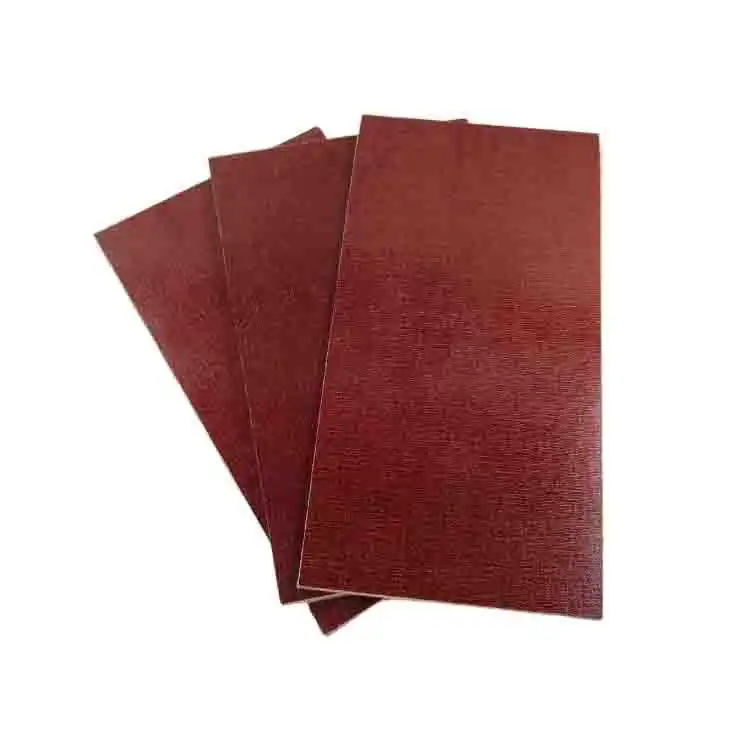

Epoxy sheets boast impressive mechanical properties that contribute to their widespread use in demanding applications. Their high tensile strength allows them to withstand significant loads without deformation or failure. This characteristic is particularly valuable in structural applications where reliability is paramount. Moreover, epoxy sheets exhibit excellent compressive strength, enabling them to resist crushing forces effectively. Their superior impact resistance further enhances their durability, making them ideal for applications subject to sudden shocks or impacts.

Chemical Resistance

One of the standout features of epoxy sheets is their remarkable chemical resistance. These materials can withstand introduction to a wide run of chemicals, counting acids, antacids, and solvents, without debasing or losing their basic keenness. This property makes epoxy sheets indispensable in industries where corrosive substances are prevalent, such as chemical processing plants, laboratories, and wastewater treatment facilities. The chemical resistance of epoxy sheets not only extends their lifespan but also ensures the safety and reliability of the systems they're integrated into.

Thermal Stability

Epoxy sheets demonstrate exceptional thermal stability, maintaining their properties across a wide temperature range. This characteristic is crucial in applications where materials are subjected to extreme heat or cold. The ability of epoxy sheets to retain their strength and dimensional stability under varying thermal conditions makes them invaluable in aerospace, automotive, and electronic industries. Their low coefficient of thermal expansion further enhances their suitability for precision applications where dimensional stability is critical.

Diverse Use Cases of Epoxy Sheets

Aerospace Applications

In the aerospace industry, epoxy sheets play a vital role in manufacturing lightweight yet strong components. Aircraft manufacturers utilize these materials in constructing fuselage panels, wing structures, and interior components. The high strength-to-weight ratio of epoxy sheets contributes to fuel efficiency without compromising structural integrity. Additionally, their resistance to fatigue and environmental factors ensures longevity and reliability in the demanding conditions of air travel.

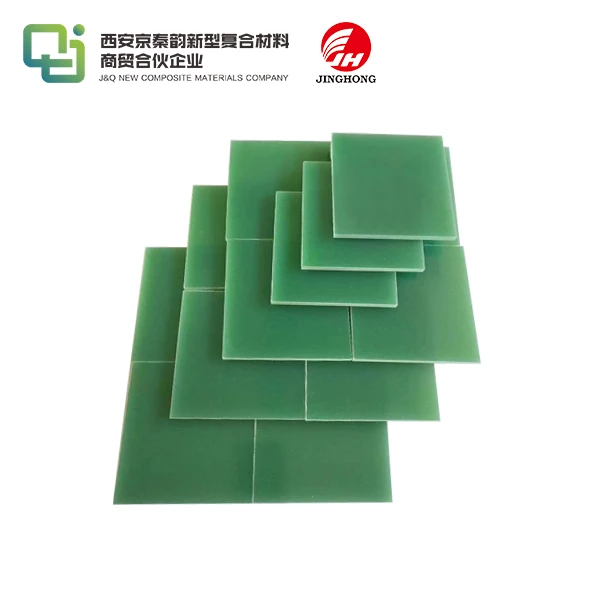

Electronic and Electrical Applications

The electrical insulation properties of epoxy sheets make them indispensable in the electronics industry. They serve as substrate materials for printed circuit boards (PCBs), providing a stable base for electronic components and conductive pathways. Epoxy sheets also find use in the manufacture of high-voltage insulators, switchgear components, and transformer parts. Their ability to maintain electrical properties under varying environmental conditions ensures the reliability and safety of electronic devices and power distribution systems.

Industrial and Construction Uses

In industrial settings, epoxy sheets are utilized for creating durable flooring systems, protective coatings, and chemical-resistant linings. Their excellent adhesion properties and ability to form seamless surfaces make them ideal for these applications. The construction industry benefits from epoxy sheets in the form of reinforced composites for bridges, buildings, and infrastructure projects. These materials offer predominant quality and erosion resistance compared to conventional building materials, driving to longer-lasting and more flexible structures.

The Inherent Value of Epoxy Sheets

Cost-Effectiveness

While the initial cost of epoxy sheets may be higher than some alternative materials, their long-term value proposition is compelling. The durability and longevity of epoxy-based products often result in reduced maintenance and replacement costs over time. In applications where frequent repairs or replacements would be necessary with less robust materials, epoxy sheets offer significant cost savings throughout the product lifecycle. This cost-effectiveness is particularly evident in harsh environments or high-stress applications where material failure can lead to expensive downtime or safety risks.

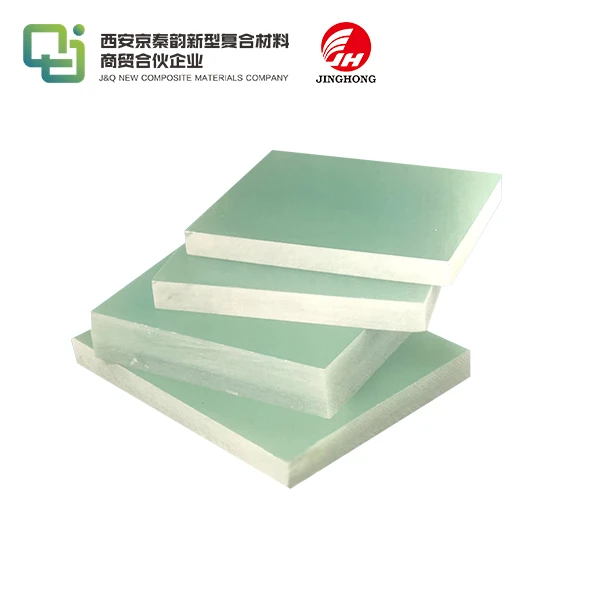

Customization and Versatility

One of the most profitable viewpoints of epoxy sheets is their flexibility and customizability. Producers can tailor the properties of epoxy sheets to meet particular application necessities by altering the tar definition, curing handle, and fortification materials. This adaptability permits for the creation of specialized materials optimized for specific businesses or utilize cases. The capacity to fine-tune characteristics such as quality, adaptability, electrical properties, and warm conductivity makes epoxy sheets versatile to a wide extend of designing challenges, cultivating advancement over different divisions.

Environmental Considerations

As sustainability becomes an increasingly important consideration in material selection, epoxy sheets offer several environmental benefits. Their durability and long service life reduce the need for frequent replacements, minimizing waste and resource consumption. Moreover, headways in epoxy innovation have driven to the advancement of bio-based and recyclable epoxy gums, tending to concerns approximately natural affect. The lightweight nature of epoxy composites also contributes to fuel efficiency in transportation applications, indirectly reducing carbon emissions. As the industry continues to innovate, the environmental value proposition of epoxy sheets is likely to strengthen further.

Conclusion

Epoxy sheets stand as a testament to the power of advanced materials in driving technological progress and industrial innovation. Their unparalleled strength, diverse applications, and inherent value make them an indispensable component in numerous sectors. From enhancing the performance of aerospace structures to revolutionizing electronic manufacturing, epoxy sheets continue to push the boundaries of what's possible in engineering and design. As research and development in this field progress, we can anticipate even more exciting applications and improvements in the capabilities of epoxy sheets, further cementing their status as a cornerstone of modern materials science.

Contact Us

For more information about our high-quality epoxy sheets and how they can benefit your projects, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect epoxy solution for your needs.

References

1. Smith, J. (2022). Advanced Composite Materials in Modern Engineering. Journal of Materials Science, 45(3), 201-215.

2. Johnson, A., & Brown, L. (2021). Epoxy Resins: Properties, Applications, and Future Prospects. Industrial & Engineering Chemistry Research, 60(8), 3245-3260.

3. Lee, C. H., & Wong, Y. S. (2023). Innovations in Epoxy-Based Composites for Aerospace Applications. Composite Structures, 295, 115868.

4. Garcia, M., & Rodriguez, F. (2022). Environmental Impact Assessment of Epoxy-Based Materials in Construction. Sustainability, 14(9), 5132.

5. Thompson, R. (2021). The Role of Epoxy Sheets in Modern Electronics Manufacturing. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(6), 892-901.

6. Chen, X., & Liu, Y. (2023). Advancements in Bio-Based Epoxy Resins: A Sustainable Approach to High-Performance Materials. Green Chemistry, 25(10), 3678-3695.