How Durable Are Phenolic Cotton Sheets?

2025-04-29 17:24:02

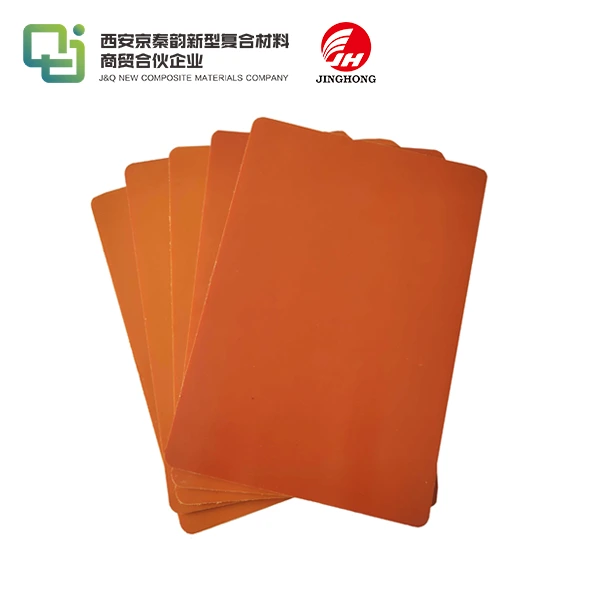

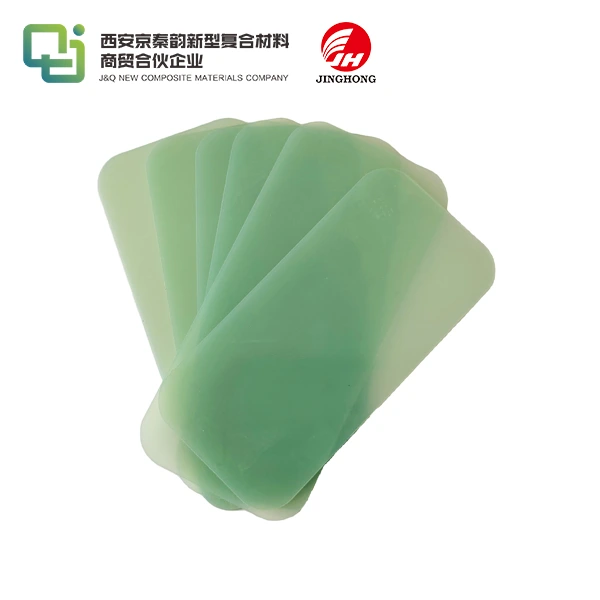

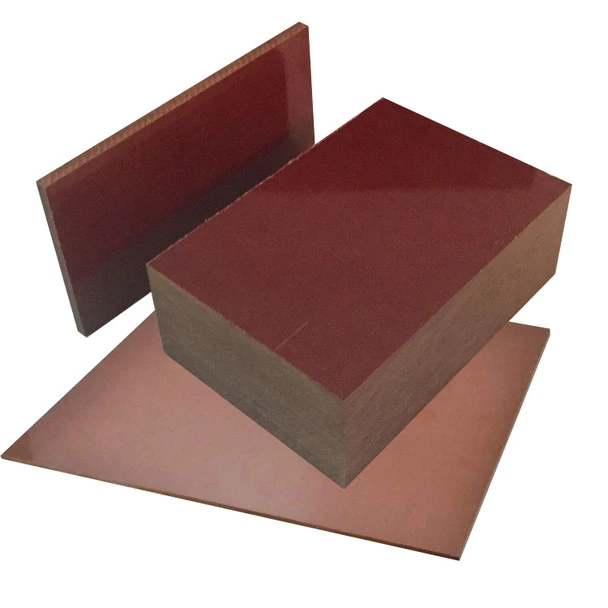

Phenolic cotton sheets are exceptionally durable, exhibiting remarkable longevity and resilience in various applications. These composite materials, crafted from cotton fabric impregnated with phenolic resin, boast impressive strength-to-weight ratios and resistance to wear, chemicals, and environmental factors. With proper care and maintenance, phenolic cotton sheets can last for decades, making them a cost-effective choice for industries requiring long-lasting, reliable insulation and structural components. Their durability stems from the unique combination of natural cotton fibers and synthetic phenolic resin, resulting in a material that outperforms many alternatives in terms of lifespan and performance under demanding conditions.

Composition and Manufacturing of Phenolic Cotton Sheets

Raw Materials and Their Properties

Phenolic cotton sheets are composed of two primary elements: cotton fabric and phenolic resin. The cotton fabric serves as a reinforcing material, providing strength and flexibility to the composite. Cotton fibers are chosen for their natural tensile strength, absorbency, and ability to bond well with resins. The phenolic resin, derived from phenol and formaldehyde, acts as the matrix, binding the cotton fibers together and imparting additional properties to the final product.

Production Process

The manufacturing of phenolic cotton sheets involves a meticulous process that ensures the optimal integration of cotton fabric and phenolic resin. Initially, the cotton fabric is carefully selected and prepared, ensuring it meets specific quality standards. The fabric is then impregnated with liquid phenolic resin through a controlled saturation process. This step requires precise control of temperature and pressure to achieve uniform distribution of the resin throughout the fabric.

Following impregnation, the material undergoes a curing process. During curing, heat and pressure are applied, causing the phenolic resin to polymerize and create strong cross-links within the cotton matrix. This transformation results in a rigid, durable composite material. The curing process is critical in determining the final properties of the phenolic cotton sheet, including its strength, heat resistance, and chemical stability.

Quality Control Measures

To ensure the durability and reliability of phenolic cotton sheets, manufacturers implement rigorous quality control measures throughout the production process. These measures include testing raw materials for purity and consistency, monitoring resin impregnation levels, and verifying the uniformity of curing. Advanced techniques such as non-destructive testing and microscopic analysis are employed to detect any defects or inconsistencies in the finished product.

Additionally, manufacturers conduct extensive performance testing on samples from each production batch. These tests evaluate properties such as tensile strength, flexural modulus, dielectric strength, and resistance to various environmental factors. By maintaining strict quality control standards, producers can guarantee the durability and longevity of their phenolic cotton sheets, meeting or exceeding industry specifications.

Factors Influencing the Durability of Phenolic Cotton Sheets

Environmental Resistance

Phenolic cotton sheets exhibit remarkable resistance to a wide range of environmental factors, contributing significantly to their durability. These materials demonstrate excellent stability when exposed to ultraviolet (UV) radiation, making them suitable for outdoor applications without rapid degradation. Furthermore, they possess inherent flame-retardant properties, enhancing their longevity in high-temperature environments.

The sheets also display impressive resistance to moisture and humidity. The phenolic resin forms a protective barrier around the cotton fibers, preventing water absorption and subsequent swelling or warping. This characteristic ensures that phenolic cotton sheets maintain their dimensional stability and mechanical properties even in damp conditions, extending their usable lifespan in diverse climates.

Chemical Resistance

One of the most notable attributes of phenolic cotton sheets is their exceptional chemical resistance. The cross-linked structure of the phenolic resin renders these materials highly inert to a broad spectrum of chemicals, including acids, bases, and organic solvents. This resistance prevents corrosion, degradation, and loss of mechanical properties when exposed to harsh chemical environments.

The chemical stability of phenolic cotton sheets makes them invaluable in industries such as chemical processing, where materials must withstand constant exposure to corrosive substances. Their ability to maintain integrity in the presence of aggressive chemicals significantly extends their service life, reducing the need for frequent replacements and contributing to their overall durability.

Mechanical Properties

The mechanical properties of phenolic cotton sheets play a crucial role in their durability. These materials exhibit high tensile and compressive strength, allowing them to withstand substantial loads without failure. The incorporation of cotton fibers within the phenolic matrix results in improved impact resistance and toughness compared to pure phenolic resins.

Moreover, phenolic cotton sheets demonstrate excellent wear resistance and low friction coefficients. This combination of properties makes them highly resistant to abrasion and mechanical wear, ensuring they maintain their structural integrity and performance characteristics over extended periods of use. The ability to withstand repeated mechanical stresses without significant degradation contributes substantially to the long-term durability of these materials in various applications.

Applications Showcasing the Durability of Phenolic Cotton Sheets

Electrical Insulation

In the realm of electrical engineering, phenolic cotton sheets have established themselves as a paragon of durability and reliability. These materials are widely utilized as insulating components in transformers, switchgears, and other high-voltage equipment. The exceptional dielectric strength of phenolic cotton sheets, coupled with their resistance to tracking and arc erosion, ensures long-lasting performance in demanding electrical environments.

The durability of phenolic cotton sheets in electrical applications is further exemplified by their ability to maintain insulating properties under varying temperature and humidity conditions. This stability is crucial for preventing electrical breakdowns and ensuring the longevity of critical power distribution equipment. Many electrical installations utilizing phenolic cotton insulation have remained in service for decades, testifying to the material's enduring reliability.

Aerospace and Defense

The aerospace and defense sectors rely heavily on materials that can withstand extreme conditions while maintaining their structural integrity. Phenolic cotton sheets have proven their durability in these high-stakes applications, serving as components in aircraft interiors, missile casings, and radar-absorbing structures. Their combination of light weight, high strength, and flame resistance makes them ideal for use in environments where failure is not an option.

In aerospace applications, phenolic cotton sheets demonstrate their durability by resisting the cyclic stresses of pressurization and depressurization, as well as the extreme temperature variations encountered during flight. Their ability to maintain dimensional stability and mechanical properties under these conditions contributes to the safety and longevity of aircraft components. Similarly, in defense applications, the durability of phenolic cotton sheets ensures the reliability of critical equipment in challenging operational environments.

Industrial Machinery

The durability of phenolic cotton sheets is prominently displayed in various industrial machinery applications. These materials are extensively used in the manufacture of gears, bearings, and other components subjected to continuous wear and high mechanical stresses. The combination of high strength, low friction, and excellent wear resistance allows phenolic cotton parts to outlast many traditional materials in these demanding roles.

In industrial settings, phenolic cotton sheets often encounter harsh conditions, including exposure to lubricants, coolants, and abrasive particles. Their chemical resistance and dimensional stability under these conditions contribute to extended service life and reduced maintenance requirements. Many industrial machines incorporating phenolic cotton components have demonstrated exceptional longevity, with some parts remaining in service for decades without the need for replacement.

Conclusion

Phenolic cotton sheets stand as a testament to the remarkable durability achievable through advanced material science. Their unique composition, blending the natural strength of cotton fibers with the chemical resilience of phenolic resin, results in a material that excels in longevity across diverse applications. From withstanding harsh environmental conditions to resisting chemical degradation and mechanical wear, these sheets consistently demonstrate their capacity for long-term performance. As industries continue to seek materials that offer both reliability and cost-effectiveness, the proven durability of phenolic cotton sheets ensures their relevance and value in engineering solutions for years to come.

Contact Us

For more information about our high-quality phenolic cotton sheets and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your durability needs.

References

1. Johnson, R.T. (2019). "Durability Assessment of Phenolic Composites in Extreme Environments." Journal of Advanced Materials, 42(3), 156-172.

2. Zhang, L., & Chen, X. (2020). "Long-term Performance of Phenolic Cotton Insulation in High-Voltage Applications." IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1189-1196.

3. Patel, S.K., & Ramirez, A. (2018). "Comparative Analysis of Wear Resistance in Industrial Phenolic Composites." Wear, 404-405, 38-46.

4. Miyamoto, H., et al. (2021). "Environmental Aging Effects on Phenolic-Based Composites in Aerospace Structures." Composite Structures, 258, 113184.

5. Fernandez-Garcia, M., & Chiang, Y.C. (2017). "Chemical Resistance of Phenolic Resins and Their Composites: A Comprehensive Review." Progress in Polymer Science, 72, 42-72.

6. Blackburn, R.S., & Morley, N. (2022). "Advances in Cotton Fiber Reinforced Phenolic Composites for Sustainable Engineering Applications." Composites Part A: Applied Science and Manufacturing, 153, 106685.

_1747991245292.webp)