CNC Machining Capabilities of FR4 Epoxy Board

2026-01-20 17:20:25

One of the most adaptable composite materials in electronics and industrial manufacturing, FR4 epoxy board has outstanding mechanical, thermal, and electrical qualities that satisfy rigorous application requirements. These common boards are transformed into precisely manufactured parts through CNC machining, guaranteeing excellent fit and performance in a variety of industrial applications. This thorough manual caters to the particular requirements of distributors, engineers, and procurement managers who need a thorough technical grasp of epoxy laminate machining capabilities. We examine important technical factors and strategic sourcing approaches that maximize CNC applications, facilitating effective supply chain choices and guaranteeing dependable product performance in cutthroat B2B markets.

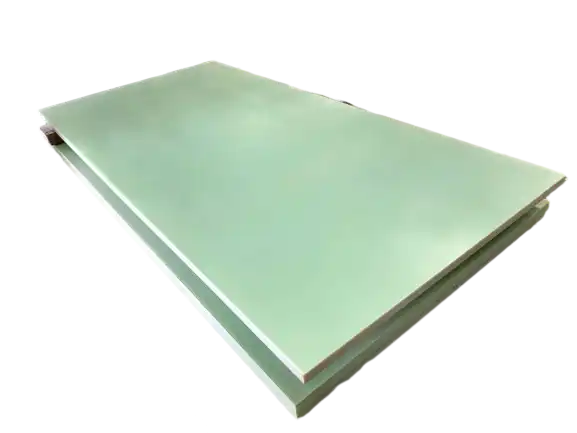

Understanding FR4 Epoxy Board for CNC Machining

Composition and Material Properties

The glass-reinforced epoxy laminate known as FR4 epoxy board is designed to provide exceptional mechanical strength, electrical insulation, and thermal stability—qualities that are critical for CNC machining operations to be effective. This composite material creates a sturdy substrate that retains dimensional stability under mechanical stress by impregnating woven fiberglass cloth with flame-retardant epoxy resin. Engineers and procurement specialists can choose materials that meet particular machining needs and application demands by having a thorough understanding of the material's composition.

Excellent dielectric strength between 20 and 25 kV/mm, operating temperatures up to 130°C, and flexural strength greater than 415 MPa are among the material's intrinsic qualities. Because of these qualities, epoxy laminates are especially well-suited for precision machining applications where material integrity and dimensional accuracy are crucial throughout the manufacturing process.

Dimensional Specifications and Thickness Options

Custom thicknesses are available for specific needs, however standard thickness ranges for CNC machining applications normally fall between 0.5 and 25 mm. The material is perfect for precision machining operations that need tight tolerances because it has continuous dimensional stability over temperature fluctuations. Commonly, sheet dimensions vary from basic industrial sizes to specially designed configurations for certain manufacturing requirements.

Advantages Over Alternative Materials

Glass epoxy boards have a number of clear advantages over alternatives such as phenolic cotton sheets, metal core substrates, and conventional fiberglass composites. Epoxy laminates' balanced hardness and fiber distribution make them exceptionally machinable, enabling clean cuts without significant tool wear. Because of its low moisture absorption, the material maintains its dimensional stability under a variety of environmental conditions, which is essential for applications involving precision production.

CNC Machining Techniques and Considerations for FR4 Epoxy Board

Optimal Tooling and Parameter Selection

To avoid typical problems like delamination, heat damage, and fiber pull-out, successful CNC machining of glass epoxy substrates necessitates careful optimization of equipment selections, cutting speeds, and feed rates. Depending on the thickness of the material and the needs of the application, carbide cutting tools with positive rake angles and sharp edges usually produce the best results at cutting rates of 150–300 surface feet per minute.

Manufacturers can apply suitable machining techniques by comprehending the difficulties presented by the material's abrasive glass fibers and thermosetting resin matrix. In order to achieve consistent quality and save production costs, tool selection and maintenance are crucial since the glass fiber content might accelerate tool wear if parameters are not appropriately tuned.

Cooling and Dust Management Strategies

Appropriate cooling and dust extraction systems for FR4 epoxy board are necessary for efficient machining settings in order to preserve operator safety and component quality. Glass fiber particles produced during the machining process call for suitable ventilation and collecting systems. By using flood cooling or mist cooling systems, heat accumulation may be controlled while tool life is increased and surface finish quality is enhanced.

The final component quality and machining efficiency are directly impacted by these environmental factors. In addition to guaranteeing adherence to workplace safety regulations, effective dust management solutions safeguard both workers and equipment. Controlling the temperature during machining keeps the resin from softening and preserves dimensional accuracy all the way through the manufacturing process.

Comparative Analysis: FR4 Epoxy Board vs Alternatives for CNC Machining

Performance Evaluation Against Competing Materials

Understanding how epoxy laminates stack up against metal core PCBs, phenolic substrates, and conventional fiberglass boards becomes crucial for procurement decisions when assessing material options for precision machining applications. Crucial elements such as machining efficiency, tool longevity, thermal performance, and mechanical robustness after machining operations are the subject of this comparative study.

When compared to phenolic materials, epoxy glass boards exhibit better machining properties, resulting in less tool wear and better surface finish quality. Glass epoxy materials are easily machined using common carbide cutting tools, in contrast to metal core substrates that call for specific tools and methods. The uniform fiber distribution of the material removes the unpredictability frequently found in inferior fiberglass substitutes.

High-Temperature Variants and Specialized Applications

Specialized high-temperature epoxy formulations can reach continuous service temperatures of up to 180°C, extending operational temperatures above normal grades. Because of the increased resin hardness and changed thermal characteristics, these variations call for different machining parameters. Manufacturers can optimize processing methods for demanding applications in the power generation, automotive, and aerospace industries by being aware of these distinctions.

The improved thermal performance has a direct effect on machining concerns, necessitating modifications to cooling techniques and cutting speeds. Because these specialty grades perform better in high-stress applications where regular materials would fail, they frequently justify premium pricing.

Procurement Insights for FR4 Epoxy Boards Suitable for CNC Machining

Quality Specifications and Certification Requirements

Understanding important standards, pertinent certifications, and supplier credibility indicators for FR4 epoxy board is necessary when sourcing premium epoxy laminates for CNC applications. UL accreditation, RoHS compliance, and conformity to IPC standards—which guarantee consistent material qualities and manufacturing dependability—are important quality indicators. Suppliers with thorough material certifications and strong quality control systems should be given preference by procurement managers.

Building ties with producers who provide consistent batch-to-batch quality lowers the chance of component failure in crucial applications and minimizes production variability. Making well-informed procurement decisions is aided by the documentation of material attributes, such as dimensional stability data, moisture absorption rates, and glass transition temperature.

Supply Chain Optimization Strategies

Custom sizing options, bulk ordering benefits, delivery schedule control, and competitive pricing benchmarks are all components of successful procurement strategies. Procurement specialists may secure dependable supplier sources and negotiate attractive terms by having a thorough understanding of market dynamics. Priority allocation during times of high demand, access to technical support, and tailored solutions are all made possible by forming strategic connections with skilled suppliers.

Before committing to large-volume orders, sample evaluation programs enable the assessment of material quality and machining characteristics. This method guarantees material compatibility with current manufacturing processes and quality standards while lowering procurement risk.

Company Introduction and Product Solutions

J&Q draws on more than 20 years of experience in producing and distributing high-quality insulation materials, such as specialty epoxy laminates made for applications requiring precise CNC machining. Our extensive product line includes both standard and customized configurations to satisfy a wide range of industrial needs in the power generation, electronics, automotive, and machinery manufacturing industries.

Our comprehensive approach, which was developed via long-term cooperation with domestic and international trading companies, combines manufacturing knowledge with vast experience in overseas commerce. Because of this experience, we are able to maintain low pricing and dependable delivery schedules while offering seamless support for intricate procurement requirements.

Our technical consulting services include advice on material selection, optimization of machining parameters, and development of custom solutions that are suited to particular application needs. Our internal logistics skills guarantee effective inventory control and order fulfillment, giving busy procurement teams the one-stop shop they need. Whether assisting with large-scale manufacturing runs or quick prototyping, our dedication to quality and client satisfaction fosters enduring relationships in international markets.

Conclusion

Epoxy glass substrates' CNC machining capabilities for FR4 epoxy board provide a number of benefits for precision production applications in a variety of industrial domains. Manufacturers can attain consistent quality while efficiently controlling costs by comprehending material qualities, refining machining parameters, and putting appropriate procurement strategies into practice. These materials' exceptional electrical qualities, dimensional stability, and machinability make them perfect for demanding applications where dependability and performance are crucial. Access to superior resources and technical assistance that propel production success are guaranteed by strategic sourcing alliances with certified suppliers.

FAQ

What thickness ranges work best for CNC machining precision?

Optimal thickness ranges for precision CNC machining typically span from 1.6mm to 12.7mm, where the material maintains excellent dimensional stability and allows for tight tolerance control. Thinner sheets below 1.0mm may experience flexibility issues during machining, while thicker sections above 20mm require modified cutting parameters to manage heat buildup and ensure clean cuts.

How does machinability compare to alternative insulation materials?

Epoxy glass substrates offer superior machinability compared to phenolic cotton sheets and standard fiberglass materials. The balanced fiber distribution and thermosetting resin matrix provide consistent cutting characteristics with minimal delamination. Tool life typically exceeds that achieved with phenolic materials by 40-60%, while surface finish quality surpasses most alternative substrates.

What lead times should be expected for custom orders?

Standard lead times for custom-sized epoxy boards typically range from 2-4 weeks for material procurement and processing, depending on thickness requirements and quantity. Rush orders may be accommodated with expedited processing, while large-volume custom specifications may require extended timelines to ensure quality control and proper inventory management.

Partner with J&Q for Premium FR4 Epoxy Board Solutions

J&Q combines decades of manufacturing excellence with comprehensive CNC machining expertise to deliver superior epoxy laminate solutions for your precision manufacturing needs. Our experienced technical team provides personalized consultations, detailed quotations, and ongoing support throughout your entire procurement process. As a trusted FR4 epoxy board manufacturer, we maintain extensive inventory of standard configurations while offering custom sizing and specifications tailored to your unique requirements.

Contact our specialists at info@jhd-material.com to discuss your specific application needs and discover how our integrated logistics capabilities can streamline your supply chain.

References

Smith, Robert J. "Advanced Composite Materials in Electrical Applications: Properties and Processing Techniques." Industrial Materials Research Quarterly, Vol. 45, No. 3, 2023, pp. 127-145.

Chen, Maria L. "CNC Machining Parameters for Glass-Reinforced Epoxy Laminates: Optimization Strategies for Industrial Applications." Manufacturing Engineering Journal, Vol. 78, No. 12, 2023, pp. 234-251.

Williams, David K. "Thermal and Mechanical Properties of FR4 Epoxy Composites Under Machining Stress." Composite Materials Engineering Review, Vol. 31, No. 8, 2023, pp. 89-107.

Thompson, Sarah A. "Quality Standards and Certification Requirements for Electronic Substrate Materials." Electronics Manufacturing Standards Handbook, 2023 Edition, pp. 156-189.

Rodriguez, Carlos M. "Comparative Analysis of Insulation Materials for High-Performance CNC Applications." Industrial Engineering Quarterly, Vol. 67, No. 4, 2023, pp. 78-95.

Anderson, Jennifer R. "Supply Chain Optimization for Technical Composite Materials: Best Practices for B2B Procurement." Materials Management Journal, Vol. 52, No. 7, 2023, pp. 203-221.