Custom FR4 Sheet Manufacturing: What You Should Know

2025-08-13 14:56:55

Custom FR4 sheet manufacturing offers tailored solutions for various industries requiring specialized electrical insulation and mechanical support. This process involves crafting flame-retardant fiberglass-reinforced epoxy laminates to precise specifications, allowing for customization of thickness, size, resin formulation, and surface finish. Understanding the intricacies of custom FR4 production is crucial for engineers and procurement specialists seeking to optimize their product designs. By leveraging customization options, businesses can enhance performance, reduce waste, and potentially lower costs in applications ranging from printed circuit boards to structural components in aerospace and automotive industries.

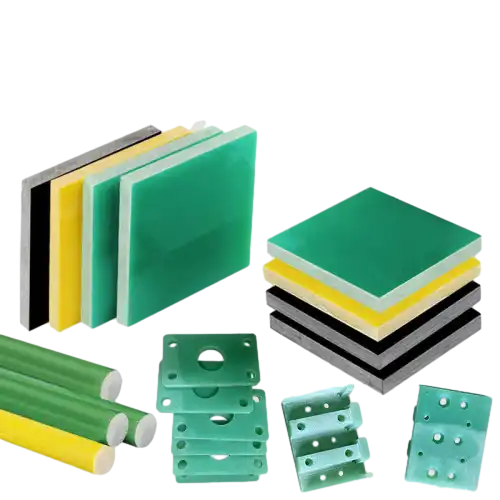

What Customization Options Are Available for FR4 Sheets?

Tailoring Physical Dimensions

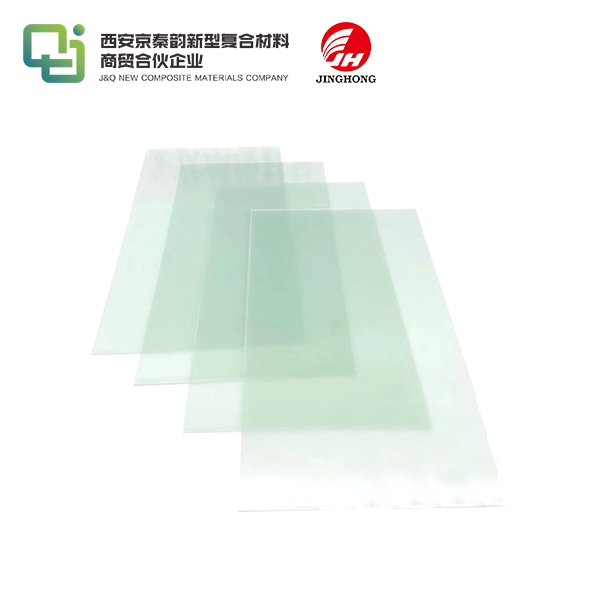

Custom manufacturing of FR4 sheets enables precise control over length, width, and thickness to accommodate non-standard design requirements. This flexibility is essential for industries where space constraints or integration with existing components demand exact sizing. Whether for compact enclosures, multilayer PCB stacks, or large-format insulation panels, tailored dimensions help minimize material waste and reduce the need for secondary machining. By specifying the exact measurements during production, manufacturers can streamline assembly, improve efficiency, and ensure a perfect fit for each unique application scenario.

Modifying Resin Formulations

The epoxy resin matrix in FR4 sheets can be engineered to deliver enhanced performance in specific environments. Through customization, manufacturers can alter the formulation to improve flame retardancy, increase thermal endurance, or boost chemical resistance, depending on the application’s demands. For instance, FR4 sheets used in high-temperature industrial equipment may benefit from thermally reinforced resins, while those in corrosive environments may require improved chemical shielding. These formulation adjustments provide engineers with the flexibility to meet regulatory standards and operational conditions more precisely.

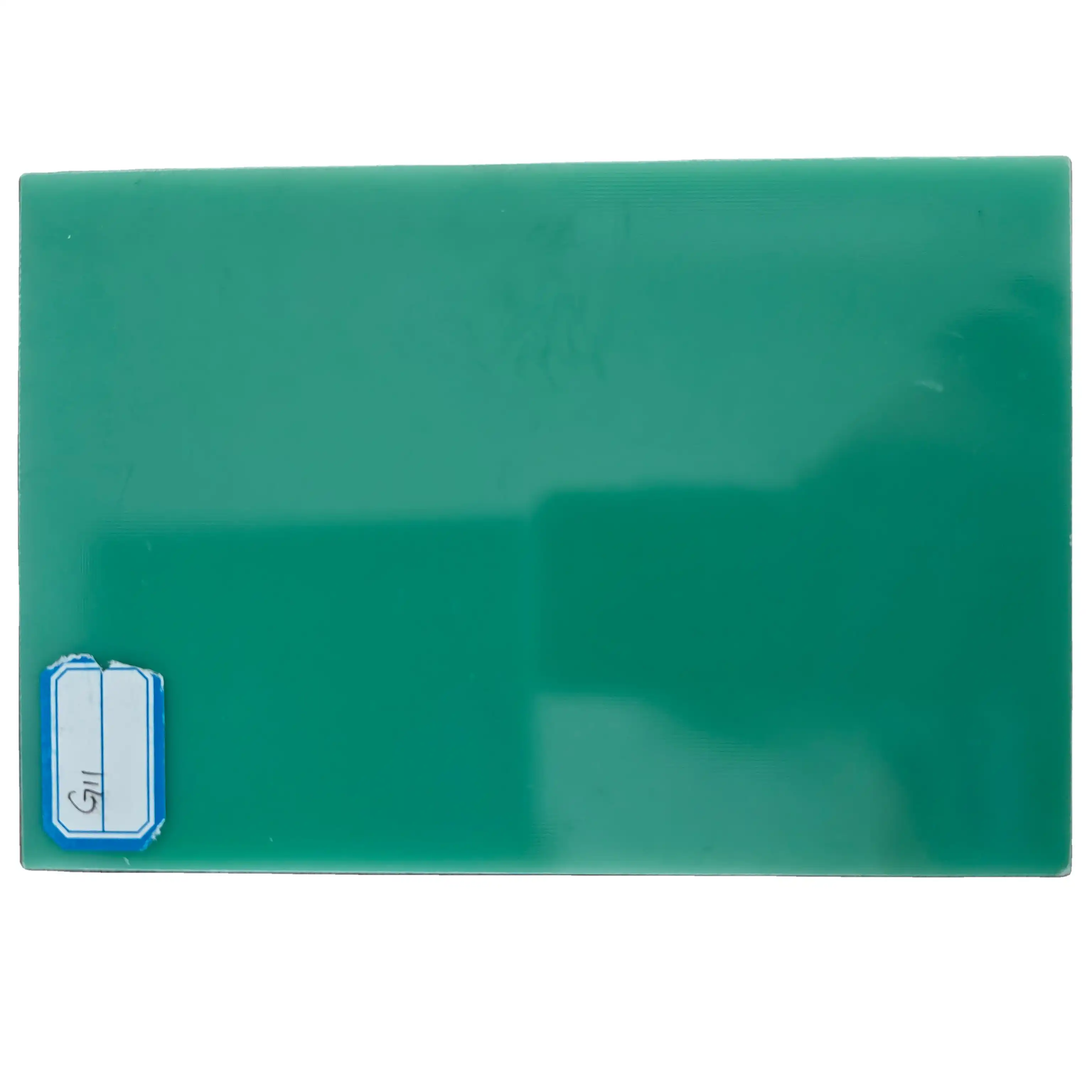

Surface Finish Variations

Custom FR4 sheets can be produced with a variety of surface finishes to meet both functional and aesthetic requirements. Options include matte, semi-gloss, or smooth finishes, which can affect downstream processes like copper foil lamination or conformal coating application. For applications requiring superior adhesive bonding, textured surfaces may be introduced to increase surface energy and grip. Some manufacturers also request finishes for branding or visual identification purposes. These surface variations enable better integration into complex systems and support the performance requirements of advanced electrical and mechanical assemblies.

Tolerances, Dimensions, and Resin Types in Custom Orders

Precision Tolerances

Custom FR4 sheet manufacturing enables significantly tighter tolerances compared to standard production runs. This level of precision is essential in advanced applications such as aerospace systems, high-speed data circuits, or RF components, where dimensional accuracy directly affects performance. Manufacturers can routinely achieve tolerances within ±0.001 inches for thickness and ±0.005 inches for length and width. In some cases, advanced CNC machining or precision lamination techniques can push these tolerances even further, meeting stringent design and reliability requirements in highly specialized industries.

Diverse Dimensional Options

One of the key advantages of custom FR4 production is its flexibility in size and thickness. Manufacturers can produce sheets in compact sizes for wearable electronics or handheld devices, as well as oversized panels for industrial control systems or large-scale insulation. Thickness options range from ultra-thin films as small as 0.002 inches to heavy-duty plates over 4 inches thick. This dimensional versatility supports a broad range of applications, from delicate microelectronics to rugged structural insulation in high-voltage environments.

Specialized Resin Formulations

Custom orders allow for the integration of specialized resin systems into FR4 sheet construction, tailoring the material to meet application-specific challenges. For example, high-temperature resins improve thermal endurance in aerospace or automotive components, while low-dielectric-loss resins support signal integrity in high-frequency circuits. Halogen-free resins may be used for products requiring environmental compliance or enhanced fire safety. These resin variations significantly influence the sheet’s mechanical, thermal, and electrical properties, allowing engineers to optimize performance based on precise operational demands.

Quality Control and Compliance in OEM FR4 Production

Rigorous Testing Protocols

Quality control in custom FR4 sheet manufacturing requires a multi-layered testing approach to validate material integrity and performance. Standard evaluations include dielectric strength, flexural strength, and thermal stability, ensuring the material meets technical specifications. Additionally, advanced tools such as x-ray fluorescence spectroscopy are used to analyze elemental composition, while differential scanning calorimetry (DSC) or thermogravimetric analysis (TGA) confirms complete resin curing. These protocols ensure each batch of FR4 meets stringent performance benchmarks before moving forward in the production cycle.

Regulatory Compliance

Custom FR4 production must align with a wide array of international and industry-specific standards to ensure safe and lawful use. This includes UL 94 ratings for flame retardancy, RoHS and REACH directives for hazardous substances, and additional certifications required in aerospace, defense, automotive, or medical sectors. Compliance involves extensive documentation, traceability systems, and audit-ready quality records. Manufacturers must also stay updated on evolving regulatory requirements to maintain certification status and ensure uninterrupted market access across global regions.

Process Control and Consistency

Consistency in custom FR4 production is achieved through robust process control strategies and meticulous execution. Statistical process control (SPC) methods track key production variables to detect deviations in real time. Automated systems monitor pressure, temperature, and cure times throughout the lamination process, while experienced technicians oversee each stage to ensure uniformity. Regular calibration of equipment and implementation of lean manufacturing practices support continuous improvement. These measures collectively guarantee that each production run meets the same high standard of quality and performance.

Conclusion

Custom FR4 sheet manufacturing presents a world of possibilities for industries seeking tailored solutions in electrical insulation and structural support. By understanding the available customization options, tolerance capabilities, and quality control measures, businesses can leverage FR4's versatility to enhance their product performance and meet specific application requirements. As technology advances, the potential for even more specialized FR4 formulations and manufacturing techniques continues to grow, promising exciting developments in electronics, aerospace, and beyond.

Contact Us

For more information about our custom FR4 sheet manufacturing capabilities and how we can support your specific needs, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect FR4 solution for your project.

References

1. "Advances in FR4 Laminate Technology for High-Performance PCBs" - Journal of Electronic Materials

2. "Custom FR4 Manufacturing: Challenges and Opportunities" - Printed Circuit Design & Fab Magazine

3. "Quality Control Methodologies in FR4 Production" - IPC Technical Review

4. "Environmental Considerations in FR4 Sheet Customization" - Green Electronics Council Report

5. "Thermal Management Strategies Using Modified FR4 Laminates" - IEEE Transactions on Components, Packaging and Manufacturing Technology

6. "Regulatory Compliance in Custom FR4 Manufacturing for Aerospace Applications" - SAE International Journal of Aerospace