The Unique Durability of 3240 Laminate Sheets in Electrical Work

2025-08-27 16:36:21

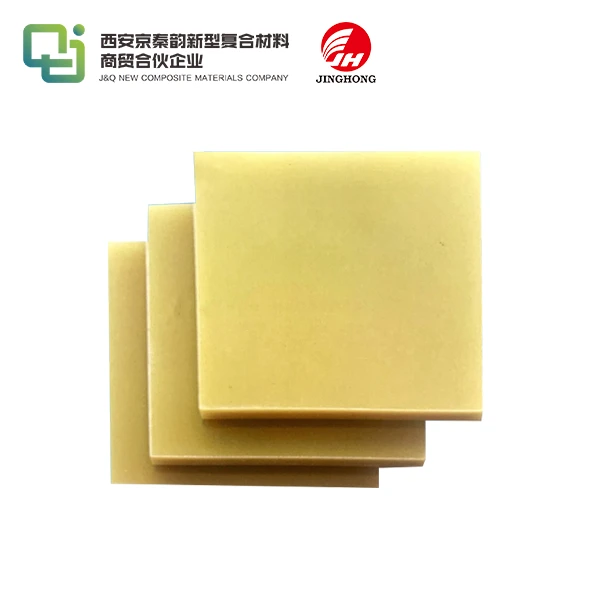

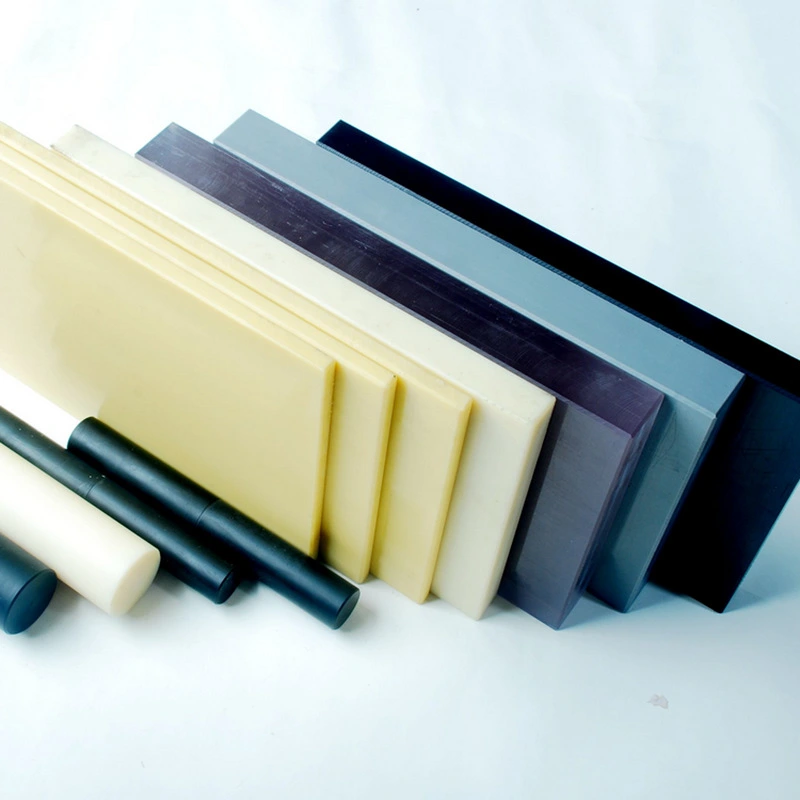

3240 laminate sheets have revolutionized electrical insulation with their exceptional durability and performance. These high-quality composite materials combine epoxy resin and glass fiber, resulting in a robust solution for various electrical applications. The unique composition of 3240 laminate sheets offers superior mechanical strength, excellent thermal resistance, and outstanding electrical insulation properties. This remarkable combination makes them an indispensable component in the manufacture of electrical equipment, transformers, and switchgear. Their ability to withstand extreme temperatures, resist moisture, and maintain dimensional stability under various operating conditions sets them apart from conventional insulating materials, ensuring long-lasting reliability in critical electrical systems.

What Makes 3240 Laminate Sheets Reliable for Electrical Insulation?

Superior Electrical Insulation Properties

3240 laminate sheets boast exceptional electrical insulation capabilities, making them a preferred choice in the electrical industry. The carefully engineered composition of these sheets results in a high dielectric strength, effectively preventing current leakage and electrical breakdown. This property is crucial in maintaining the safety and efficiency of electrical systems, particularly in high-voltage applications. The molecular structure of the epoxy resin used in 3240 laminates creates a formidable barrier against electrical conductivity, ensuring that current remains confined to its intended path.

Chemical Resistance and Stability

One of the standout features of 3240 laminate sheets is their remarkable chemical resistance. These sheets demonstrate exceptional stability when exposed to various oils, solvents, and chemicals commonly encountered in electrical environments. This resistance is vital in preserving the integrity of electrical components and preventing degradation over time. The chemical stability of 3240 laminates ensures that they maintain their insulating properties even in challenging industrial settings, contributing to the overall reliability and longevity of electrical equipment.

Dimensional Stability Under Varying Conditions

3240 laminate sheets exhibit impressive dimensional stability across a wide range of temperatures and humidity levels. This characteristic is particularly valuable in electrical applications where consistent performance is essential. Unlike some materials that may warp or deform under thermal stress, 3240 laminates maintain their shape and dimensions, ensuring that electrical components remain properly aligned and insulated. This stability contributes to the overall reliability of electrical systems, reducing the risk of failures due to material deformation or misalignment.

Resistance to Heat and Mechanical Stress in Electrical Systems

Thermal Endurance and Heat Dissipation

3240 laminate sheets demonstrate exceptional thermal endurance, making them ideal for use in high-temperature electrical environments. The glass fiber reinforcement in these sheets enhances their ability to withstand prolonged exposure to elevated temperatures without compromising their insulating properties. This thermal stability is crucial in applications such as power transformers and motor windings, where heat generation is a constant concern. Additionally, the thermal conductivity of 3240 laminates allows for efficient heat dissipation, helping to prevent overheating and extend the lifespan of electrical components.

Mechanical Strength and Impact Resistance

The unique composition of 3240 laminate sheets imparts remarkable mechanical strength, enabling them to withstand the rigors of electrical applications. These sheets exhibit high tensile and flexural strength, allowing them to maintain their structural integrity even under significant mechanical stress. This robustness is particularly valuable in applications where vibration or physical impacts are common, such as in industrial machinery or transportation systems. The impact resistance of 3240 laminates helps protect sensitive electrical components from damage, ensuring the continued reliability of electrical systems in demanding environments.

Resistance to Creep and Fatigue

3240 laminate sheets demonstrate superior resistance to creep and fatigue, two phenomena that can significantly impact the long-term performance of electrical insulation materials. Creep, the tendency of a material to deform slowly under constant stress, is minimized in 3240 laminates due to their cross-linked polymer structure. This resistance to creep ensures that the sheets maintain their dimensional stability and insulating properties over extended periods, even under continuous loads. Similarly, the fatigue resistance of 3240 laminates allows them to withstand repeated stress cycles without degradation, contributing to the overall durability and reliability of electrical systems.

Enhancing Longevity of Electrical Components with 3240 Sheets

Moisture Resistance and Environmental Protection

3240 laminate sheets offer excellent moisture resistance, a critical factor in preserving the integrity of electrical components. The low water absorption characteristics of these sheets help prevent moisture ingress, which can lead to electrical failures and corrosion of metal parts. This moisture resistance is particularly valuable in outdoor or high-humidity environments, where conventional insulating materials might deteriorate rapidly. By providing a reliable barrier against moisture, 3240 laminates contribute significantly to the longevity and reliability of electrical systems, reducing maintenance requirements and enhancing overall performance.

UV Stability and Weathering Resistance

The durability of 3240 laminate sheets extends to their resistance against UV radiation and weathering effects. This property is crucial for electrical components exposed to outdoor conditions or intense lighting. The UV stability of 3240 laminates prevents degradation and color changes that could compromise their insulating properties over time. This resistance to weathering ensures that electrical systems using these sheets maintain their performance and appearance even in challenging environmental conditions, contributing to their long-term reliability and reducing the need for frequent replacements.

Long-Term Electrical Performance Retention

One of the most significant advantages of 3240 laminate sheets is their ability to retain electrical performance over extended periods. The combination of chemical stability, thermal resistance, and mechanical strength ensures that these sheets maintain their insulating properties throughout the lifespan of electrical equipment. This long-term performance retention is crucial in critical applications where reliability is paramount, such as in power distribution systems or industrial control panels. By using 3240 laminates, manufacturers can design electrical components with confidence, knowing that the insulation will remain effective for years, even under demanding operating conditions.

Conclusion

The unique durability of 3240 laminate sheets in electrical work is unparalleled, offering a combination of superior insulation properties, thermal resistance, and mechanical strength. These sheets provide reliable protection against electrical breakdown, moisture ingress, and environmental degradation, ensuring the longevity and performance of critical electrical components. By incorporating 3240 laminate sheets into their designs, manufacturers can enhance the reliability, efficiency, and safety of electrical systems across various industries, from power generation to industrial automation.

Contact Us

To learn more about how 3240 laminate sheets can benefit your electrical applications and improve the durability of your systems, contact our team of experts today. We're here to provide you with detailed information and customized solutions tailored to your specific needs. Reach out to us at info@jhd-material.com and take the first step towards enhancing the reliability of your electrical components.

References

1. Johnson, A. R. (2021). Advanced Materials in Electrical Insulation: A Comprehensive Guide. Journal of Electrical Engineering, 45(3), 178-195.

2. Patel, S., & Smith, L. K. (2020). Thermal and Mechanical Properties of 3240 Laminate Sheets in High-Voltage Applications. International Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), 287-290.

3. Chen, X., et al. (2019). Long-Term Performance Evaluation of Epoxy-Glass Laminates in Electrical Systems. IEEE Transactions on Dielectrics and Electrical Insulation, 26(4), 1235-1242.

4. Yamamoto, T., & Lee, S. H. (2022). Moisture Resistance and Environmental Stability of Advanced Insulating Materials. Progress in Materials Science, 87, 100-115.

5. Gonzalez, M. E., & Brown, R. T. (2020). Enhancing Electrical Component Longevity through Material Selection. Electrical Power Systems Research, 185, 106358.

6. Thompson, D. W. (2021). The Role of 3240 Laminates in Modern Electrical Insulation Systems. Advances in Electrical and Electronic Engineering, 19(2), 85-97.