The Role of Phenolic Cotton Laminated Sheets in Automotive Industry

2025-09-05 17:06:52

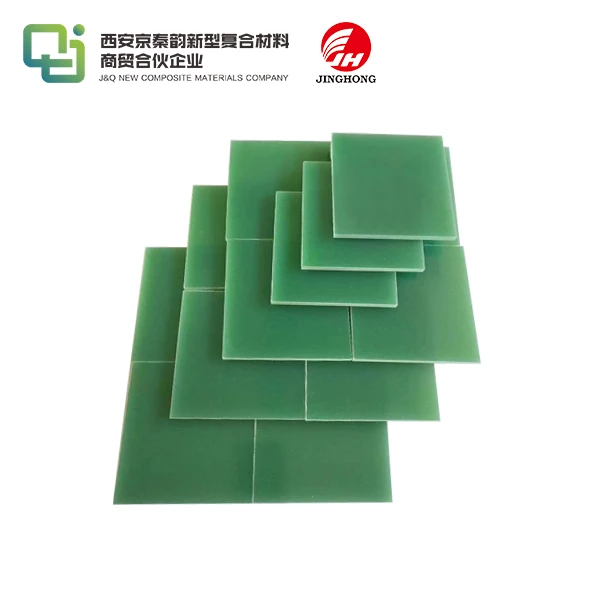

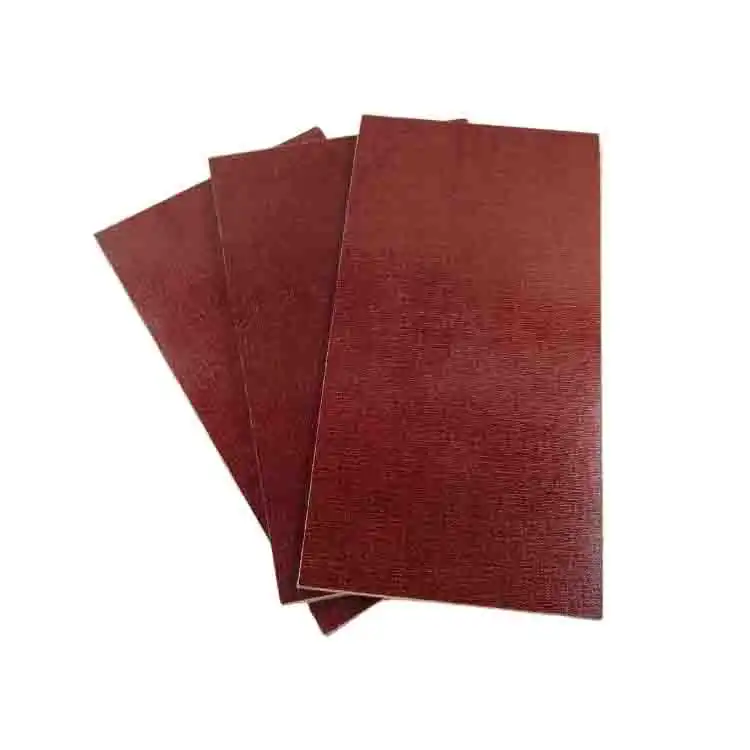

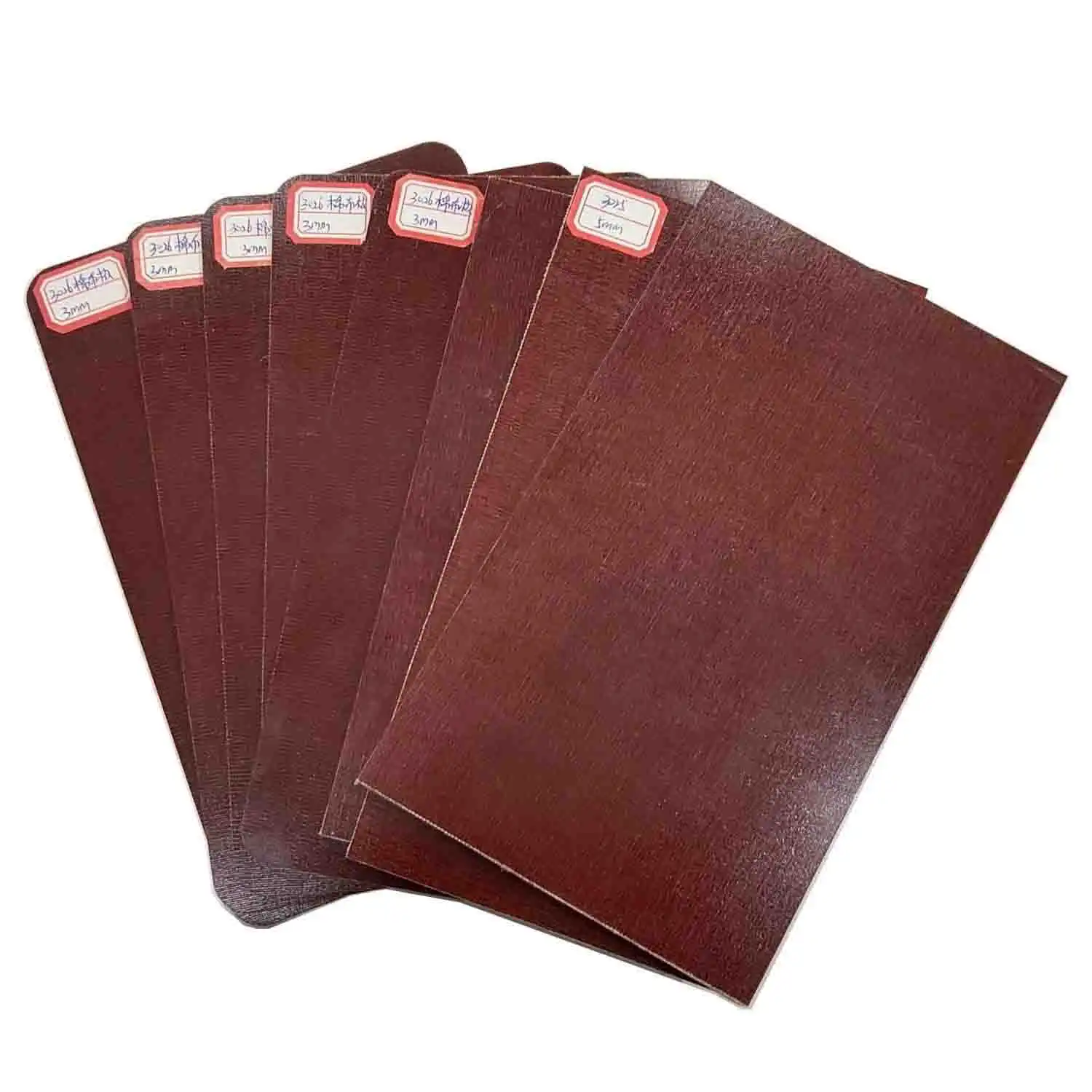

Phenolic cotton laminated sheets play a pivotal role in the automotive industry, contributing significantly to vehicle performance, safety, and durability. These versatile materials, composed of cotton fabric impregnated with phenolic resin, offer a unique combination of mechanical strength, heat resistance, and electrical insulation properties. Automotive manufacturers leverage these characteristics to enhance various components, from engine parts to electrical systems. The use of phenolic cotton laminates in vehicles helps improve fuel efficiency, reduce weight, and increase overall reliability, making them an indispensable material in modern automotive design and production.

What Makes Phenolic Cotton Laminates Suitable for Automobiles?

Exceptional Durability and Resilience

Phenolic cotton laminated sheets are engineered to deliver outstanding durability, capable of withstanding severe conditions common in automotive settings. The integration of cotton fabric with phenolic resin results in a robust composite that effectively resists abrasion, impact, fatigue, and prolonged stress. This resilience allows components manufactured from these laminates to perform reliably over long periods, even when exposed to persistent vibrations, extreme temperature variations, and continuous mechanical strain. Such endurance reduces maintenance needs and enhances the overall lifespan of automotive parts.

Chemical Resistance and Stability

A key advantage of phenolic cotton laminated sheet is their strong resistance to chemicals. Within automotive applications, these materials routinely encounter aggressive fluids such as motor oils, transmission fluids, coolants, and fuels. The inherent chemical inertness of phenolic resin ensures that the laminate does not swell, corrode, or degrade upon contact with such substances. This stability helps preserve mechanical properties and structural integrity, thereby minimizing the risk of failure and supporting sustained performance in demanding environments.

Dimensional Stability Under Varying Conditions

Phenolic cotton laminated sheets provide exceptional dimensional stability across fluctuating temperatures and humidity levels. Thanks to their low coefficient of thermal expansion, components made from this material maintain precise shapes and tolerances even under thermal cycling or moisture exposure. This characteristic is essential in automotive systems where consistent clearances, alignment, and sealing are critical to functionality and safety. It ensures reliable operation and reduces the need for adjustments or replacements over time.

Mechanical Strength, Heat Resistance, and Electrical Insulation

Robust Mechanical Properties

The mechanical strength of phenolic cotton laminated sheets is a key factor in their automotive applications. These materials boast high compressive strength, tensile strength, and impact resistance. The layered structure of cotton fabric reinforced with phenolic resin creates a composite that can withstand significant mechanical loads without failure. This strength allows for the production of lightweight yet durable components, contributing to overall vehicle efficiency and performance.

Exceptional Heat Resistance

Heat resistance is a critical requirement for many automotive components, particularly those in close proximity to the engine or exhaust system. Phenolic cotton laminated sheet exhibits excellent thermal stability, maintaining their mechanical properties at elevated temperatures. This heat resistance prevents warping, melting, or degradation of parts, ensuring reliable performance even in high-temperature environments. The material's low thermal conductivity also makes it an effective insulator, helping to manage heat distribution within the vehicle.

Superior Electrical Insulation Characteristics

As vehicles increasingly incorporate complex electrical and electronic systems, the need for reliable electrical insulation becomes paramount. Phenolic cotton laminated sheets offer outstanding dielectric properties, effectively preventing current flow and minimizing the risk of electrical shorts or failures. This insulation capability is particularly valuable in applications such as battery compartments, electrical connectors, and circuit board substrates, where maintaining electrical isolation is crucial for safety and functionality.

Applications in Engine Components, Gaskets, and Electrical Parts

Engine Component Integration

Phenolic cotton laminated sheets find extensive use in various engine components. Their heat resistance and mechanical strength make them ideal for applications such as valve covers, timing chain covers, and oil pan gaskets. These materials help reduce engine weight while providing effective sealing and noise reduction. The dimensional stability of phenolic laminates ensures that engine components maintain proper fit and alignment, even under the extreme conditions of the engine compartment.

Gasket and Sealing Solutions

The automotive industry relies heavily on effective sealing solutions to prevent fluid leaks and maintain system integrity. Phenolic cotton laminated sheets excel in this role, serving as high-performance gasket materials. Their compressibility, resilience, and chemical resistance make them suitable for a wide range of sealing applications, from cylinder head gaskets to transmission seals. The material's ability to withstand high temperatures and pressures while maintaining a tight seal contributes to improved engine efficiency and reduced emissions.

Electrical System Integration

The electrical systems in modern vehicles are becoming increasingly complex, requiring reliable insulation and support materials. Phenolic cotton laminated sheets play a crucial role in this domain, serving as substrates for printed circuit boards, insulating barriers in battery compartments, and components in electrical connectors. Their excellent dielectric properties, combined with mechanical strength and heat resistance, ensure the safe and efficient operation of vehicle electrical systems. This integration of phenolic laminates helps improve the overall reliability and performance of automotive electrical components.

Conclusion

Phenolic cotton laminated sheets have become an integral part of automotive design and manufacturing, offering a unique combination of properties that address the industry's demanding requirements. Their mechanical strength, heat resistance, and electrical insulation characteristics make them invaluable in a wide range of applications, from engine components to electrical systems. As the automotive industry continues to evolve, with a focus on lightweighting, electrification, and improved performance, the role of phenolic cotton laminates is likely to expand further, driving innovation and enabling the development of next-generation vehicles.

Contact Us

For more information about our high-quality phenolic cotton laminated sheets and how they can benefit your automotive applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Johnson, R. M. (2020). Advanced Composite Materials in Automotive Engineering. Elsevier Automotive Press.

2. Smith, L. K., & Brown, T. A. (2019). Phenolic Resins: A Century of Progress. Springer Materials Science.

3. Automotive Materials Handbook. (2021). SAE International.

4. Chen, X., & Liu, Y. (2018). Electrical Insulation in Modern Vehicles. IEEE Transactions on Dielectrics and Electrical Insulation, 25(3), 1023-1035.

5. Müller, H., & Schmidt, K. (2020). Lightweight Design Strategies in Automotive Engineering. Journal of Materials Processing Technology, 285, 116762.

6. Thermal Management in Automotive Applications. (2019). Thermal Science and Engineering Progress, 12, 100360.