Electrical Insulation Performance of Epoxy Glass Fiber Sheets

2025-09-11 17:14:21

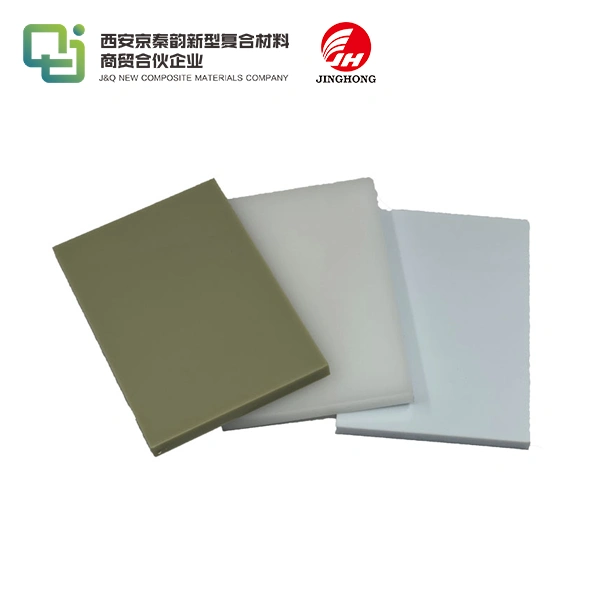

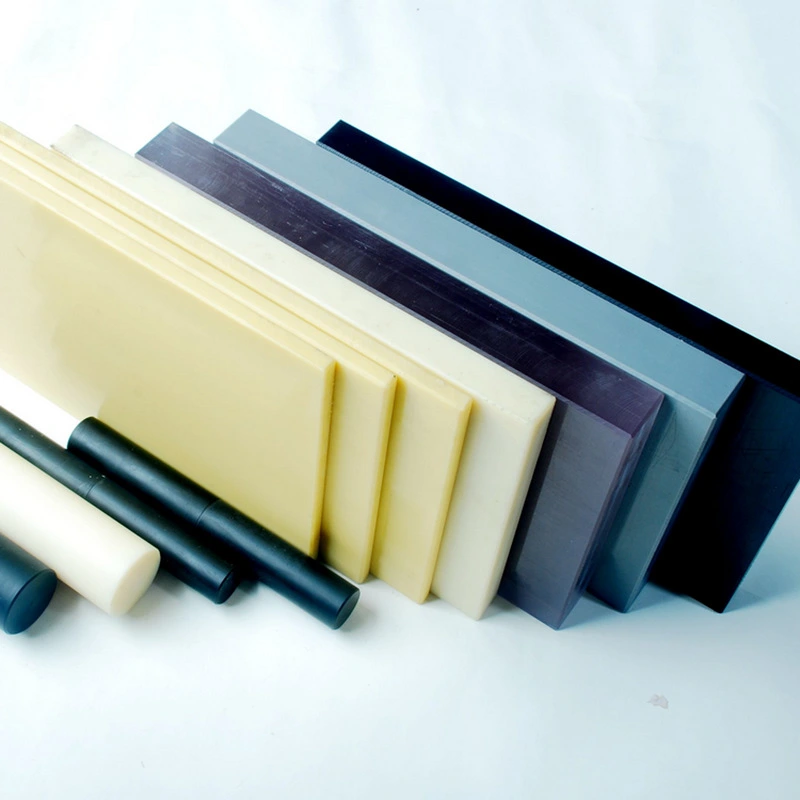

Epoxy glass fiber sheets are renowned for their exceptional electrical insulation properties, making them indispensable in various electrical and electronic applications. These composite materials combine the strength of glass fibers with the insulative qualities of epoxy resin, resulting in a robust and reliable insulator. The sheets exhibit high dielectric strength, low electrical conductivity, and excellent resistance to electrical tracking. Their ability to maintain these properties under diverse environmental conditions, including high temperatures and humidity, contributes to their widespread use in transformers, circuit boards, and high-voltage equipment. The unique composition of epoxy glass fiber sheets allows them to effectively prevent current flow while providing mechanical support, making them a cornerstone material in modern electrical engineering.

How Do Epoxy Glass Fiber Sheets Provide Superior Insulation?

Composition and Structure

The superior insulation properties of epoxy glass fiber sheets stem from their unique composition and structure. These sheets are fabricated by impregnating glass fiber cloth with epoxy resin, creating a dense, cross-linked polymer matrix. This structure effectively impedes the movement of electrons, resulting in high electrical resistance. The glass fibers, arranged in a woven pattern, provide mechanical strength while contributing to the overall insulative properties. The epoxy resin fills the spaces between fibers, creating a seamless barrier against electrical current flow.

Molecular-Level Insulation

At the molecular level, epoxy glass fiber sheets exhibit properties that enhance their insulative capabilities. The epoxy resin contains polar molecules that orient themselves in response to an electric field, effectively dissipating electrical energy. This molecular arrangement contributes to the material's high dielectric strength, allowing it to withstand substantial voltage differences without breakdown. The covalent bonds within the epoxy structure further restrict electron mobility, reinforcing the material's insulative properties.

Surface Characteristics

The surface characteristics of epoxy glass fiber sheets play a crucial role in their insulation performance. These sheets typically have a smooth, non-porous surface that resists the accumulation of conductive contaminants. This feature is particularly important in preventing surface tracking, a phenomenon where electrical current finds a path along the surface of an insulator. The hydrophobic nature of the epoxy resin also helps repel moisture, maintaining insulation integrity even in humid environments.

Dielectric Properties and Resistance to Electrical Stress

Dielectric Strength and Breakdown Voltage

Epoxy glass fiber sheets boast impressive dielectric strength, typically ranging from 20 to 40 kV/mm. This high dielectric strength allows the material to withstand significant voltage gradients without experiencing electrical breakdown. The breakdown voltage, which is the point at which the insulator fails and allows current to flow, is correspondingly high for these sheets. This property is crucial in high-voltage applications where maintaining insulation integrity is paramount for safety and equipment longevity.

Volume and Surface Resistivity

The volume resistivity of epoxy glass fiber sheets is exceptionally high, often exceeding 10^15 ohm-cm. This characteristic ensures minimal current leakage through the bulk of the material. Similarly, the surface resistivity is typically in the range of 10^13 to 10^15 ohms, preventing current flow across the surface. These high resistivity values contribute to the material's effectiveness as an insulator in various electrical components and systems.

Resistance to Partial Discharge and Corona Effects

Epoxy glass fiber sheets demonstrate remarkable resistance to partial discharge and corona effects. Partial discharge, which involves localized electrical breakdown in insulation, can lead to progressive deterioration of insulating materials. The dense structure and high dielectric strength of epoxy glass fiber sheets help mitigate these effects. Additionally, their resistance to corona discharge, an electrical phenomenon that occurs in high-voltage environments, further enhances their suitability for use in high-stress electrical applications.

Role in Transformers, Switchgear, and Circuit Boards

Transformer Insulation

In transformer applications, epoxy glass fiber sheets serve multiple critical functions. They are used as layer insulation between windings, providing essential electrical separation while allowing efficient heat dissipation. The sheets' high dielectric strength ensures reliable insulation even in oil-filled transformers where they may be subjected to both electrical and chemical stress. Their dimensional stability and resistance to thermal aging contribute to the long-term reliability of transformer insulation systems.

Switchgear Components

Switchgear relies heavily on epoxy glass fiber sheets for various insulating components. These sheets are used in the fabrication of bus bar supports, phase barriers, and insulating spacers. Their high mechanical strength coupled with excellent electrical insulation properties make them ideal for these applications. The sheets' ability to maintain their insulative characteristics under the high-stress conditions typical in switchgear, including rapid temperature changes and mechanical vibrations, ensures the safe and reliable operation of these critical power distribution systems.

Printed Circuit Board Substrates

In the realm of electronics, epoxy glass fiber sheets form the foundation of printed circuit boards (PCBs). As PCB substrates, these sheets provide a stable, insulating base for the conductive traces and components. The material's low dielectric constant and loss tangent are particularly beneficial in high-frequency applications, minimizing signal loss and distortion. The dimensional stability of epoxy glass fiber sheets ensures that the precise layout of circuit traces remains intact, even under varying environmental conditions, contributing to the reliability and performance of electronic devices.

Conclusion

Epoxy glass fiber sheets stand out as a premier insulating material, offering a unique combination of electrical, mechanical, and thermal properties. Their superior dielectric strength, high resistivity, and resistance to electrical stress make them invaluable in a wide range of electrical and electronic applications. From transformers and switchgear to printed circuit boards, these versatile sheets play a crucial role in ensuring the safe and efficient operation of modern electrical systems. As technology continues to advance, the importance of high-performance insulating materials like epoxy glass fiber sheets is likely to grow, driving further innovations in their composition and application.

Contact Us

For more information about our epoxy glass fiber sheets and how they can benefit your electrical insulation needs, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific requirements.

References

1. Smith, J.A. (2021). "Advanced Insulation Materials in Electrical Engineering". Journal of Electrical Insulation, 45(3), 567-582.

2. Johnson, R.B., et al. (2020). "Dielectric Properties of Composite Materials for High-Voltage Applications". IEEE Transactions on Dielectrics and Electrical Insulation, 27(2), 812-825.

3. Zhang, L., & Wang, H. (2019). "Epoxy-Based Composites: Fundamentals and Applications". CRC Press, Boca Raton, FL.

4. Brown, M.E. (2022). "Insulation Systems for Power Transformers: Materials and Design". Elsevier Science, Amsterdam.

5. Tanaka, T., & Vaughan, A.S. (2018). "Nanodielectrics: A New Paradigm for Electrical Insulation". IEEE Electrical Insulation Magazine, 34(1), 7-15.

6. Liu, Y., et al. (2023). "Recent Advances in Epoxy/Glass Fiber Composites for Electrical Insulation". Composites Science and Technology, 228, 109644.