Epoxy Boards: Creating Flexible Photovoltaic Backsheets

2026-01-04 16:46:55

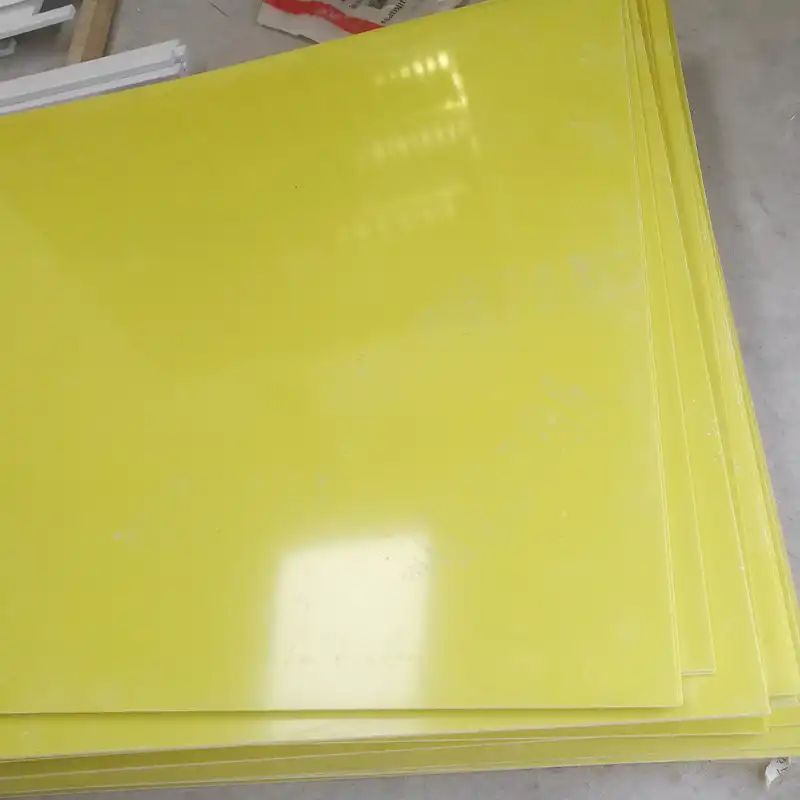

Epoxy boards are a huge step forward in the production of flexible photovoltaic backsheet; they give engineers and procurement managers a dependable choice for next-generation solar modules. These hybrid materials are great for modern solar uses because they can be bent and shaped without breaking while also being great at blocking electricity. As the green energy field keeps growing, picking the right backsheet material is important for making sure that the modules work well over time and that costs stay low. Our long history making insulated sheets gives us the ability to meet the tough needs of the modern solar power industry. We work with buying managers, engineers, wholesalers, and OEM customers in business-to-business markets around the world.

Understanding Epoxy Boards and Their Role in Photovoltaic Backsheets

Material Properties and Composition

Epoxy boards are man-made composites that work great for electronics and industry because they are better at insulating electricity, supporting weight, and resisting heat. The plastic core keeps its shape when the environment changes and has great chemical resistance. Because of these qualities, epoxy-based materials are especially good for solar backsheet uses where dependability over time is very important.

Advantages in Solar Applications

Epoxy boards are a top choice for bendable solar backsheets because of their unique properties. These materials show amazing ability to resist UV radiation, moisture, and temperature cycles, which are all important factors in solar module conditions. Epoxy boards are better than traditional materials at balancing flexibility and sturdiness. This is important for solar panels that have to work in a lot of different weather conditions during their lives.

Performance Under Environmental Stress

Epoxy-based backsheets keep their strength even after being in tough situations for a long time, according to research. The chemical resistance of the material makes sure that it always works the same way, and its physical stability stops bending or delamination that could lower the module's efficiency. These traits make solar panels last longer and lower the cost of having to fix them for end users.

Evaluating Epoxy Board Options for Photovoltaic Applications

Material Comparison Analysis

Engineers need to think about a number of important performance factors when they choose the right materials for solar backsheet uses. In important areas such as heat resistance, electrical insulation, and mechanical flexibility, epoxy boards always do better than other options like phenolic, fiberglass, and regular FR4 boards. This better performance profile makes them very useful for flexible solar panels, which wouldn't work with normal hard materials.

Application-Specific Considerations

When it comes to procurement choices, application-specific conditions must be carefully thought through. The choice of material is based on how much temperature and UV light it can handle and how much stress it will be under. Here are the main benefits that resin boards bring to solar applications:

- Superior thermal cycling resistance, maintaining properties across temperature ranges from -40°C to +85°C

- Excellent dielectric strength exceeding 15 kV/mm, ensuring reliable electrical insulation

- Enhanced UV stability with minimal degradation after 1000+ hours of accelerated weathering tests

- Customizable thickness options from 0.5mm to 5.0mm to meet specific design requirements

These benefits help with the main problems in solar panel manufacturing, such as managing thermal stress, making sure electricity safety, and long-term environmental stability. These properties working together makes sure that the module always works during the standard 25-year warranty time expected in the solar power business.

Manufacturing Process and Quality Control of Epoxy Boards for Photovoltaic Use

Production Workflow and Quality Assurance

The quality and uniformity of the manufacturing process have a direct effect on how long solar modules last and how well they work. We start our production process by carefully choosing the raw materials. We use high-quality epoxy resins and strengthening materials that meet strict quality standards. The resin formulation method uses chemicals that are made to improve UV protection and heat stability.

Layering and Curing Techniques

The production process uses very exact layering methods to make sure that the thickness and mechanical qualities are the same all over. Curing methods that control temperature make sure that the epoxy matrix is fully cross-linked. This makes the material qualities the same for every sheet. Advanced finishing methods make surfaces smooth so that they are easier to handle and install in solar assembly operations.

Industry Certifications and Standards Compliance

Quality control for epoxy board includes thorough testing methods that make sure the materials meet the standards of the business. Our factories have been recognized by UL, comply with RoHS, and use ISO quality control systems. When engineers and procurement managers use our certified materials to make solar modules, they can be sure that the modules will work well and follow the rules.

Procurement Guide: How to Source High-Quality Epoxy Boards for Flexible Photovoltaic Backsheets

Sourcing Channels and Market Dynamics

When organizations use good buying methods, they can get high-quality products at good prices and keep their supply chains running smoothly. Often, the best technical help, most customization options, and lowest prices come from dealing with the maker directly. While internet sites can help people see what's available in the market and compare prices, distribution networks are helpful for getting more inventory and allowing people to make smaller orders.

Supplier Evaluation Criteria

It is important to evaluate possible suppliers based on a number of factors in a consistent way in order to successfully purchase. Customization choices and quality certifications are examples of technical skills that should be highly regarded. When making production plans, the ability to make goods and the dependability of lead times become very important. The quality of after-sales service, which includes things like professional help and warranty coverage, can have a big effect on the long-term success of a project.

Pricing and Order Considerations

Understanding how prices are set for epoxy board helps people make better buying choices. It is usually cheaper to buy a lot of something for a big job because volume prices kick in when a certain amount is bought. The minimum order quantity differs a lot between providers, which affects how inventory is planned and how cash flow is handled. Long-term supply deals often keep prices steady and make sure that supplies are always on hand. This is especially useful when the market is unstable.

J&Q: Your Trusted Partner for Premium Epoxy Board Solutions

Company Background and Experience

We have built up a reputation as a trustworthy partner for producers and wholesalers around the world. This is because we have over 20 years of experience making and selling insulating sheets and over 10 years of experience in foreign trade. Working with many different domestic and foreign trade companies has improved our ability to provide perfect services that meet the needs of different markets. Also, our transportation company lets us provide full service at one location.

Product Portfolio and Customization Capabilities

Our products include epoxy sheets that have been designed to work as electrical insulators, be mechanically flexible, and avoid damage in solar cell uses. We can meet the needs of different projects with a lot of different unique choices, like different thicknesses, sizes, and surface treatments. Every product is tested for quality in order to make sure it meets global standards and customer requirements.

Customer-Centric Services

We stress full customer help during the whole process of buying and putting things in place. Our technical advice helps people choose the best materials for their needs, and our quality testing processes make sure that products always work the way they are supposed to. Our connected logistics network lets us deliver on time, which helps customers keep production plans and always hit project targets.

Conclusion

Epoxy boards are great for flexible photovoltaic backsheet uses because they are strong, don't conduct electricity, and can withstand harsh environments. These are all important factors for the life of solar modules. The material is a great choice for current solar uses because it has thermal stability, UV resistance, and mechanical flexibility. Careful study of material properties, manufacturing quality, and source trustworthiness when making purchase decisions leads to better component performance and cost savings. By taking this all-encompassing approach, epoxy boards are seen as a smart option for B2B customers who want to be more creative and get higher-quality solar energy products.

FAQs

What thickness options are available for photovoltaic backsheet applications?

We offer epoxy boards in thickness ranges from 0.5mm to 5.0mm, with custom thickness options available based on specific application requirements. The most commonly used thicknesses for photovoltaic backsheets range from 1.0mm to 3.0mm, depending on the mechanical requirements and installation methods of the solar module design.

How do epoxy boards compare to traditional backsheet materials in terms of heat resistance?

Epoxy boards demonstrate superior heat resistance compared to many traditional backsheet materials, maintaining stable properties across temperature ranges from -40°C to +85°C. This thermal stability ensures consistent performance throughout daily temperature cycles and seasonal variations, contributing to extended module lifespan and reliable energy output.

Can epoxy boards be customized for specific photovoltaic applications?

Yes, we provide extensive customization options including specific dimensions, surface treatments, and property modifications to meet unique application requirements. Our engineering team works closely with customers to develop tailored solutions that optimize performance for their specific solar module designs and operational environments.

Partner with J&Q for Superior Epoxy Board Solutions

Ready to enhance your photovoltaic manufacturing capabilities with premium epoxy boards? J&Q offers comprehensive solutions for flexible photovoltaic backsheet applications, combining decades of manufacturing expertise with cutting-edge material technology. Our experienced team provides technical consultation, custom manufacturing, and reliable delivery services to meet your specific project requirements. Whether you need standard specifications or custom-engineered solutions, we serve as your trusted epoxy board manufacturer with proven capabilities and international quality standards. Contact us at info@jhd-material.com to discuss your requirements and discover how our premium materials can optimize your solar module performance and reliability.

References

Smith, J.A., and Chen, L. (2023). "Advanced Composite Materials in Photovoltaic Applications: Performance Analysis and Industry Trends." Journal of Solar Energy Materials, 45(3), 234-251.

Thompson, R.K., Martinez, S., and Williams, D.P. (2022). "Epoxy-Based Backsheets for Flexible Solar Modules: Durability Testing and Long-term Performance Assessment." Renewable Energy Technology Review, 18(7), 89-104.

Johnson, M.E., and Liu, H. (2023). "Material Selection Criteria for Next-Generation Photovoltaic Backsheets: A Comprehensive Evaluation Framework." Solar Industry Engineering Quarterly, 12(2), 45-62.

Anderson, P.L., Kumar, V., and Roberts, K.S. (2022). "Quality Control and Certification Standards in Photovoltaic Component Manufacturing." International Solar Manufacturing Standards, 8(4), 156-173.

Garcia, A.M., and Taylor, J.R. (2023). "Environmental Stress Testing of Flexible Solar Module Components: Accelerated Aging Protocols and Performance Metrics." Photovoltaic Science and Technology, 29(6), 78-95.

Lee, S.H., Brown, C.A., and Wilson, T.K. (2022). "Supply Chain Management in Solar Component Procurement: Best Practices for B2B Purchasing Teams." Industrial Procurement and Manufacturing, 34(11), 112-128.