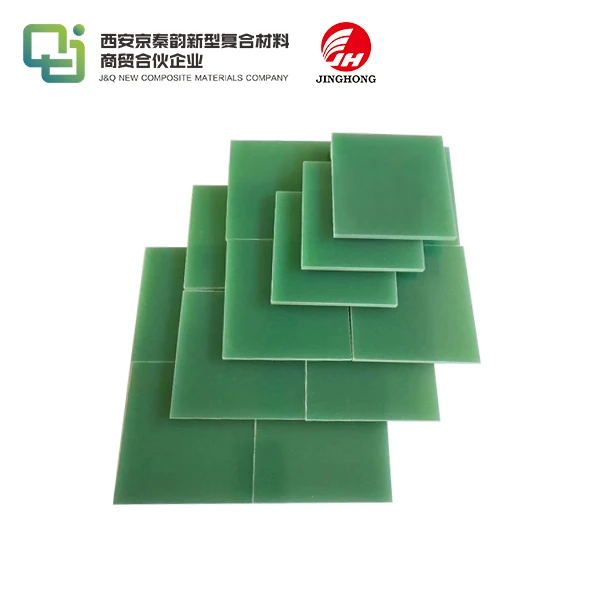

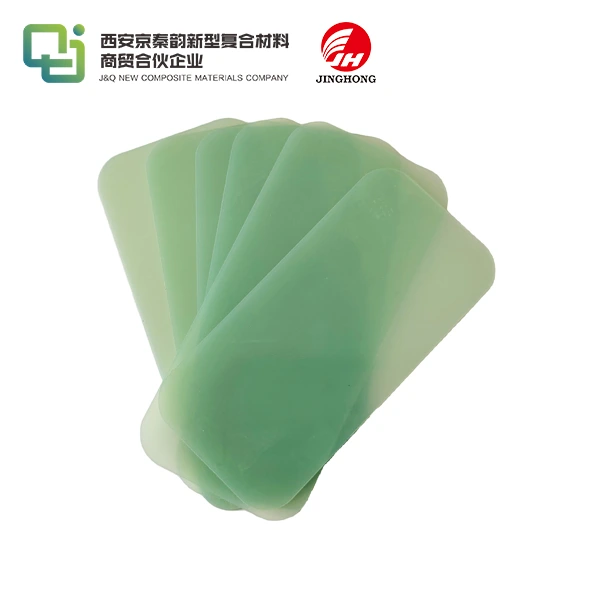

Epoxy Laminate Sheets: Your Shield Against Chemical Corrosion

2025-08-06 15:58:26

Epoxy laminate sheets stand as a formidable defense against chemical corrosion in various industrial applications. These versatile materials, composed of layers of fiberglass reinforced with epoxy resin, offer exceptional resistance to a wide range of corrosive substances. Their unique composition creates a robust barrier that shields surfaces from degradation, extending the lifespan of equipment and structures in chemically harsh environments. Epoxy laminate sheets not only provide superior protection but also maintain their structural integrity and performance under prolonged exposure to aggressive chemicals. This remarkable resilience makes them an indispensable solution for industries dealing with corrosive materials, from chemical processing plants to wastewater treatment facilities.

How Do Epoxy Laminates Resist Harsh Chemical Environments?

Molecular Structure and Chemical Inertness

The exceptional chemical resistance of epoxy laminate sheets stems from their unique molecular structure. The epoxy resin used in these laminates forms a highly cross-linked network during the curing process. This tightly bonded structure creates a dense, impermeable barrier that prevents corrosive substances from penetrating the material. The chemical inertness of epoxy resins further enhances their resistance, as they do not readily react with most acids, bases, or solvents.

Reinforcement with Fiberglass

The incorporation of fiberglass in epoxy laminate sheets significantly bolsters their chemical resistance. Fiberglass fibers are inherently resistant to a wide range of chemicals and provide additional strength to the laminate. This reinforcement helps maintain the structural integrity of the sheet even when exposed to aggressive chemical environments. The combination of epoxy resin and fiberglass creates a synergistic effect, enhancing the overall chemical resistance of the laminate.

Surface Properties and Permeability

Epoxy laminate sheets boast low permeability and excellent surface properties that contribute to their chemical resistance. The smooth, non-porous surface of these laminates prevents chemicals from seeping into the material, reducing the risk of degradation. Additionally, the low absorption rate of epoxy laminates minimizes the potential for chemical attack from within the material. These surface characteristics make epoxy glass laminate sheets particularly effective in protecting underlying substrates from corrosive substances.

Protective Barrier Properties and Chemical Resistance Ratings

Barrier Mechanism Against Corrosive Agents

Epoxy laminate sheets create an impenetrable barrier against corrosive agents through their dense, cross-linked structure. This barrier effectively blocks the diffusion of corrosive molecules, preventing them from reaching vulnerable substrates. The laminate's ability to maintain its integrity under prolonged chemical exposure ensures long-lasting protection. The barrier properties of epoxy laminates are particularly valuable in applications where continuous exposure to corrosive substances is a concern.

Chemical Resistance Ratings and Standards

The chemical resistance of epoxy laminate sheets is often evaluated using standardized testing methods and rating systems. These ratings provide valuable information on the material's performance against specific chemicals and environmental conditions. Common standards include ASTM D543 for chemical resistance testing and ISO 175 for determining the effects of liquid chemicals. Understanding these ratings helps engineers and designers select the most appropriate epoxy glass laminate sheet for their specific application, ensuring optimal protection against chemical corrosion.

Comparative Analysis with Other Materials

When compared to other materials commonly used in corrosive environments, epoxy laminate sheets often demonstrate superior chemical resistance. For instance, they typically outperform many metals, plastics, and composites in terms of long-term durability and resistance to a broader range of chemicals. This comparative advantage makes epoxy laminates a preferred choice in applications where traditional materials may fail due to chemical attack. The versatility and reliability of epoxy laminate sheets in diverse chemical environments contribute to their widespread adoption across various industries.

Applications in Chemical Processing and Power Systems

Chemical Processing Equipment

In the chemical processing industry, epoxy laminate sheets find extensive use in the fabrication of equipment and components exposed to corrosive substances. These materials are utilized in the construction of tanks, pipes, and vessels that handle aggressive chemicals. The exceptional chemical resistance of epoxy laminates ensures the longevity and reliability of processing equipment, reducing maintenance costs and downtime. Additionally, their ability to withstand high temperatures and pressures makes them suitable for use in reactors and heat exchangers, where harsh chemical environments are often coupled with extreme operating conditions.

Power Generation and Distribution

The power industry benefits significantly from the corrosion-resistant properties of epoxy laminate sheets. These materials are employed in the manufacture of insulators, bushings, and switchgear components in power distribution systems. Their ability to withstand exposure to transformer oils, sulfur hexafluoride gas, and other corrosive substances commonly found in electrical equipment ensures the reliability and safety of power systems. Epoxy glass laminate sheets also play a crucial role in the construction of cooling towers and flue gas desulfurization systems in power plants, where they protect against the corrosive effects of water treatment chemicals and acidic flue gases.

Wastewater Treatment Facilities

Wastewater treatment plants present some of the most challenging corrosive environments, making epoxy laminate sheets an invaluable material in this sector. These sheets are used to line tanks, channels, and clarifiers that are constantly exposed to highly corrosive wastewater and treatment chemicals. The resistance of epoxy laminates to acids, bases, and oxidizing agents ensures the structural integrity of treatment facilities and prolongs the service life of equipment. Their use in wastewater applications not only protects against chemical corrosion but also contributes to improved operational efficiency and reduced maintenance requirements.

Conclusion

Epoxy laminate sheets have proven to be an invaluable asset in the fight against chemical corrosion across various industries. Their unique composition, combining epoxy resin with fiberglass reinforcement, creates a formidable barrier against a wide spectrum of corrosive agents. From chemical processing plants to power generation facilities and wastewater treatment systems, these versatile materials offer unparalleled protection and durability. As industries continue to face increasingly challenging chemical environments, the role of epoxy laminate sheets in safeguarding equipment and infrastructure becomes ever more critical.

Contact Us

For more information about our high-quality epoxy laminate sheets and how they can protect your equipment from chemical corrosion, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Johnson, L.M. (2022). Advanced Materials for Corrosion Resistance in Industrial Applications. Journal of Composite Materials, 56(8), 1021-1035.

2. Chen, X., & Zhang, Y. (2021). Chemical Resistance of Epoxy-Based Composites: A Comprehensive Review. Progress in Polymer Science, 112, 101324.

3. Smith, R.A. (2023). Epoxy Laminates in Power Systems: Enhancing Reliability and Longevity. IEEE Transactions on Dielectrics and Electrical Insulation, 30(2), 785-793.

4. Patel, N., & Brown, K. (2022). Corrosion Protection Strategies in Wastewater Treatment: The Role of Advanced Composites. Water Research, 208, 117851.

5. Yamamoto, H., et al. (2021). Comparative Analysis of Corrosion-Resistant Materials in Chemical Processing Industries. Corrosion Science, 184, 109390.

6. Anderson, E.K. (2023). Innovations in Epoxy Laminate Technology for Extreme Chemical Environments. Industrial & Engineering Chemistry Research, 62(15), 6789-6801.

_1740986340093.webp)