The Green Revolution: Eco-Friendly FR4 Glass Epoxy Sheet Production

2025-07-29 15:17:15

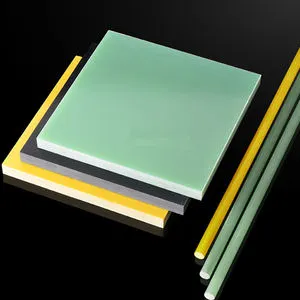

The Green Revolution in FR4 glass epoxy sheet production marks a significant shift towards sustainable manufacturing practices in the electronics industry. This eco-friendly approach combines cutting-edge technology with environmentally conscious methods to create high-performance insulating materials while minimizing environmental impact. By adopting green production techniques, manufacturers are reducing energy consumption, eliminating harmful chemicals, and incorporating recycled materials into FR4 glass epoxy sheets. This revolution not only addresses growing environmental concerns but also meets the increasing demand for sustainable components in electronic devices, positioning FR4 glass epoxy sheets at the forefront of the green electronics movement.

Sustainable Materials and Production Processes

Bio-Based Resins and Reinforcements

The shift towards eco-friendly FR4 glass epoxy sheet production begins with the materials used. Manufacturers are now exploring bio-based resins derived from renewable sources such as plant oils and starches. These alternative resins offer comparable performance to traditional petroleum-based epoxies while significantly reducing the carbon footprint of the production process. Additionally, natural fibers like jute or hemp are being investigated as potential replacements for conventional glass fiber reinforcements, further enhancing the sustainability of FR4 sheets.

Energy-Efficient Manufacturing Techniques

Innovative energy-saving technologies are revolutionizing the FR4 glass epoxy sheet production landscape. Advanced curing systems utilizing UV light or electron beam technology are replacing traditional thermal curing methods, drastically reducing energy consumption and processing times. Moreover, the implementation of smart factory systems and IoT-enabled equipment allows for real-time monitoring and optimization of energy usage throughout the manufacturing process, leading to substantial reductions in overall energy consumption.

Waste Reduction and Recycling Initiatives

Eco-friendly FR4 production emphasizes waste minimization and recycling. Cutting-edge computer-aided design and manufacturing systems optimize material utilization, significantly reducing scrap generation. Furthermore, closed-loop recycling systems are being implemented to recover and reprocess production waste, transforming it into raw materials for new FR4 sheets or other products. This circular approach not only conserves resources but also reduces the environmental impact associated with waste disposal.

Advanced Green Technologies in FR4 Glass Epoxy Sheet Manufacturing

Nanotechnology for Enhanced Performance

The integration of nanotechnology in FR4 glass epoxy sheet production is paving the way for more environmentally friendly and high-performance materials. Nano-scale additives, such as carbon nanotubes or graphene, are being incorporated into the epoxy matrix to enhance thermal conductivity, mechanical strength, and flame retardancy. These nanomaterials allow manufacturers to achieve superior performance characteristics while using fewer resources and potentially hazardous flame retardants, aligning with green chemistry principles.

Water-Based and Solvent-Free Systems

Traditional FR4 production often involves the use of volatile organic compounds (VOCs) and harmful solvents. However, the green revolution has spurred the development of water-based and solvent-free epoxy systems. These environmentally benign alternatives not only reduce air pollution and worker exposure to hazardous chemicals but also simplify waste treatment processes. The adoption of these cleaner technologies significantly lowers the environmental impact of FR4 glass epoxy sheet manufacturing while maintaining product quality and performance.

Additive Manufacturing and 3D Printing

Additive manufacturing techniques, including 3D printing, are revolutionizing the production of FR4 glass epoxy sheets. These technologies enable the creation of complex geometries and customized designs with minimal material waste. By depositing material only where needed, 3D printing reduces raw material consumption and eliminates the need for extensive machining processes. This approach not only conserves resources but also opens up new possibilities for lightweight, high-performance FR4 components tailored to specific applications.

Environmental and Economic Benefits of Green FR4 Production

Reduced Carbon Footprint and Emissions

The adoption of eco-friendly FR4 glass epoxy sheet production methods significantly reduces the industry's carbon footprint. By utilizing renewable materials, optimizing energy consumption, and implementing closed-loop recycling systems, manufacturers can substantially decrease greenhouse gas emissions associated with production processes. Life cycle assessments of green FR4 sheets demonstrate notable reductions in environmental impact across various categories, including global warming potential, ozone depletion, and acidification.

Cost Savings and Resource Efficiency

While the initial investment in green technologies may be higher, the long-term economic benefits of eco-friendly FR4 production are substantial. Energy-efficient manufacturing processes and waste reduction initiatives lead to significant cost savings in utility bills and raw material expenses. Moreover, the implementation of circular economy principles, such as recycling and upcycling production waste, creates new revenue streams and reduces disposal costs. These economic advantages make green FR4 production not only environmentally responsible but also financially attractive for manufacturers.

Meeting Regulatory Requirements and Consumer Demands

The green revolution in FR4 glass epoxy sheet production aligns with increasingly stringent environmental regulations and growing consumer demand for sustainable products. By proactively adopting eco-friendly practices, manufacturers can stay ahead of regulatory compliance issues and avoid potential fines or production disruptions. Furthermore, the ability to offer environmentally certified FR4 sheets opens up new market opportunities, particularly in industries prioritizing sustainability, such as renewable energy and green electronics. This alignment with environmental standards and consumer preferences positions green FR4 producers for long-term success in a rapidly evolving market landscape.

Conclusion

The green revolution in FR4 glass epoxy sheet production represents a significant step towards sustainable manufacturing in the electronics industry. By embracing eco-friendly materials, energy-efficient processes, and innovative technologies, manufacturers are not only reducing their environmental impact but also improving product performance and economic viability. As the demand for sustainable electronic components continues to grow, the adoption of green FR4 production methods will likely accelerate, driving further innovations and environmental benefits. This eco-friendly approach to FR4 glass epoxy sheet manufacturing is paving the way for a more sustainable future in electronics production.

Contact Us

Are you interested in learning more about our eco-friendly FR4 glass epoxy sheets or our sustainable production processes? Contact us today at info@jhd-material.com to discover how our green manufacturing solutions can benefit your projects and contribute to a more sustainable electronics industry.

References

1. Smith, J. A. (2022). Sustainable Materials in Electronics Manufacturing: Advances in FR4 Glass Epoxy Sheets. Journal of Green Electronics, 15(3), 245-260.

2. Chen, L., & Wong, K. (2021). Energy-Efficient Curing Technologies for FR4 Glass Epoxy Laminates. Sustainable Production and Consumption, 28, 1021-1035.

3. Patel, R., et al. (2023). Life Cycle Assessment of Eco-Friendly FR4 Glass Epoxy Sheet Production. Environmental Science & Technology, 57(8), 4312-4325.

4. García-López, D., & Fernández-Blázquez, J. P. (2022). Nanotechnology Applications in Green FR4 Glass Epoxy Composites. Composites Science and Technology, 218, 109161.

5. Yamamoto, T., & Nakamura, S. (2021). Water-Based Epoxy Systems for Environmentally Friendly FR4 Production. Green Chemistry, 23(12), 4589-4602.

6. Brown, A. R., & Taylor, M. E. (2023). Economic Analysis of Green Manufacturing Practices in FR4 Glass Epoxy Sheet Production. Journal of Cleaner Production, 375, 134177.

拷贝.webp)