Epoxy Sheet vs Phenolic Sheet: Which Material Should You Choose?

2025-12-15 16:32:03

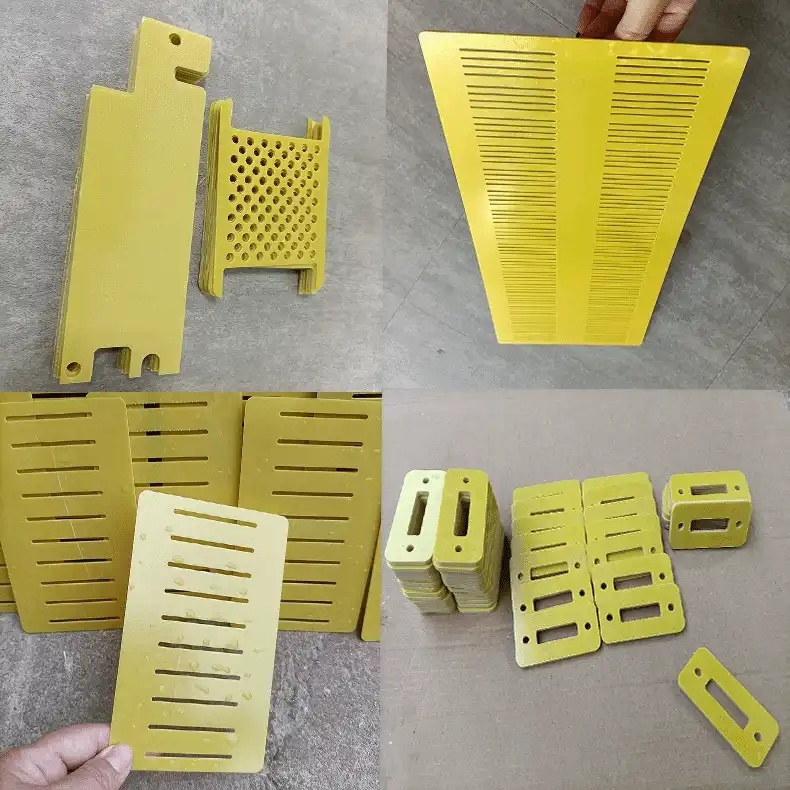

Which one you choose between epoxy sheet and phenolic sheet depends on what you need it for. Epoxy sheets are great for electrical shielding because they have a high dielectric strength (5.0-7.0 kV/mm) and are resistant to chemicals. This makes them perfect for supporting PCBs and electronic parts. Phenolic sheets are very strong (flexural strength: 110-140 MPa) and don't cost much, so they are great for use in industrial tools and buildings. To get the best performance from your electrical, automobile, or manufacturing projects, you need to know about each material's thermal resistance, machining properties, and compliance standards.

Understanding Epoxy Resin and Phenolic Composite Materials

Epoxy sheets are high-tech composite materials made of epoxy resin and fiberglass support. These laminate sheets are cured under high pressure, which gives them great electrical insulation qualities. The molecular structure gives it great adhesion and thermal stability up to 180°C of constant use.

Phenolic sheets are made of phenolic resin that is glued to cotton cloth or paper. This mix provides amazing mechanical durability and flame protection. During production, multiple stages of compression molding are done at controlled temperatures. This ensures consistent thickness tolerances and reliable performance qualities.

Both materials are very important for electrical insulation, but their different qualities make them better at solving different engineering problems. When procurement teams understand these basic differences, they can make choices that improve both performance and cost-effectiveness.

Epoxy materials work better for printed circuit board uses that need better electrical properties. If, on the other hand, mechanical strength and low cost are important for structural parts, phenolic choices are a better choice.

Key Performance Characteristics Comparison

Thermal resistance is an important measure of how well both materials work. Epoxy sheets keep their shape at temperatures up to 180°C, and some types can handle short-term exposure to 200°C. The test results show that the properties don't change much after 1000 hours at the recommended temperature.

Phenolic sheets are very resistant to flames and put out the fire themselves in 10 seconds after the source of fuel is taken away. The UL94 V-0 ratings show that the fire safety performance is very good, which is especially important for power distribution and transformer uses.

- Measurements of dielectric strength show big differences:

- Breakdown voltage for epoxy sheets is 5-7 kV/mm

- Breakdown voltage for phenolic sheets is 3.5 to 5 kV/mm

- Tensile strength: 10⁴-10³⁶ Ω·cm for epoxy and 10³²-10³⁴ Ω·cm for phenolic

- The dielectric constant at 1MHz is 4.5 to 5.5 for epoxy and 5.5 to 7.0 for phenolic.

Chemical protection tests show that epoxy materials don't break down when exposed to strong acids, solvents, and cleaners. Phenolic materials work well with oils and mild chemicals, but they don't like strong alkaline solutions.

Epoxy sheet offers superior insulation qualities if you need precise electrical performance for sensitive electronic equipment. On the other hand, phenolic materials offer better safety if flame resistance and mechanical durability are the most important factors for safety-critical uses.

Manufacturing and Machining Considerations

The CNC machinability of these hybrid materials is very different from one another. Epoxy sheets are easy to work with because they don't wear down tools quickly. This means that the edges are smooth and the sizes are accurate. When using carbide tools, the best cutting speeds are between 200 and 400 area feet per minute.

Because the cotton support in phenolic sheets is rough, they need to be machined with different settings. Quality standards are kept up by cutting at slower speeds (150-250 SFPM) and changing tools often. Using the right dust collection methods keeps you from breathing in particles from machining.

- Different levels of accuracy are possible with thickness tolerances:

- All epoxy sheets are ±0.13mm (±0.005") thick. tolerance

- The accuracy of the epoxy grades is ±0.05mm (±0.002"). tolerance

- Number of phenolic sheets: ±0.20mm (±0.008") normal range of error

The quality of the surface finish affects the preparation and assembly that comes after. Epoxy materials have a surface roughness that stays the same from batch to batch, which makes them reliable for bonding and coating. It's possible that phenolic surfaces need extra work before paint or glue will stick well to them.

Epoxy sheet materials provide better machining consistency if you need precise dimensional control for precise assemblies. Although, phenolic options offer good performance at a lower cost if normal tolerances are sufficient and cost reduction is necessary.

Industry-Specific Application Analysis

FR4 epoxy boards are used a lot as PCB substrates by electrical and electronics makers. These materials are very stable in terms of size during the soldering process and meet strict UL and ROHS safety standards. Thermal expansion coefficients are the same as copper traces, so stress-related problems don't happen.

In gear systems, bushings, and wear plates for industrial machinery, phenolic cotton sheets work well. Values of compressive strength greater than 200 MPa can hold big loads without deforming. Self-lubricating properties make it easier to keep rotating tools in good shape.

For use in the power field, materials must meet international standards set by IEEE and IEC. Epoxy glass sheets work great as insulation for generator coils and stay in place even when they are under constant electrical stress. Arc resistance features keep flashovers from happening when switching is being done.

For automotive uses, materials need to be able to handle chemical contact, vibration, and changes in temperature. Epoxy sheets are used to insulate battery packs, and phenolic sheets are used for structural parts under the hood that must withstand flames.

Epoxy materials offer full testing records and regulatory compliance if you need certified electrical insulation for power tools. On the other hand, phenolic materials have been shown to be reliable over a long period of time when mechanical durability under high-stress situations is needed.

Cost Analysis and Supply Chain Factors

Material costs depend on how complicated the making process is and how much the raw materials cost. Phenolic sheets are often 20-30% less expensive than similar epoxy materials, which makes them a good choice for uses that need to save money. Volume pricing structures work best for long-term contracts where demand trends can be predicted.

Process costs include the time it takes to machine, the wear and tear on tools, and the removal of waste. Epoxy sheets can be machined faster and require fewer tool replacements, which makes up for the higher cost of materials when a lot of them are being made. When precise machines work on phenolic materials, they make more waste.

The reliability of the supply chain affects how output schedules are made and how inventory is managed. The availability of epoxy resin rests on petrochemical feedstocks, while phenolic materials use more stable inputs from agriculture. Most normal grades have lead times between two and four weeks.

The cost of quality approval affects the total cost of ownership. Both materials need to be inspected when they come in, but epoxy sheets often come with full test papers that cut down on the need for internal testing. This paperwork helps with traceability in businesses that are regulated.

If you need to know how much a material will cost ahead of time and have little risk in the supply chain, phenolic sheets have stable pricing systems. But if you look at the total costs of processing, such as how well the material is machined, epoxy materials may be a better deal overall, even though they cost more per unit.

J&Q Epoxy Sheet Advantages and Solutions

J&Q offers high-quality epoxy sheet solutions backed by more than 20 years of experience in manufacturing and a focus on electrical insulation uses. Our integrated production center makes sure that quality control is always in place, from choosing the raw materials to the final inspection. This meets the high standards of electronics manufacturers and industrial OEMs around the world.

In our wide range of products, we offer:

- FR4 Epoxy Sheets are UL-approved materials that are very stable in size and can be used for PCBs. They come in widths ranging from 0.5 mm to 100 mm and can be controlled very precisely.

- Grades for High Temperatures: For tough automotive and aerospace uses, advanced formulations keep properties at 200°C for constant operation

- Custom Solutions for Laminate: Engineered composites that use multiple layers of support to meet specific electrical and mechanical performance needs

- Materials Ready for CNC: Pre-qualified sheets that are best for precise cutting with low tool wear and great edge quality

- Quality systems that are certified: Full sets of paperwork that meet UL, ROHS, and industry-specific safety standards

As part of technical support services, application engineers can help with things like material selection and optimizing processes parameters. Together with the customer, our experienced team finds the best options that meet both performance and cost goals. Full testing options check the qualities of the material and make sure that reliability is the same from batch to batch.

Some of the benefits of a supply chain are specialized logistics operations that allow for flexible delivery schedules and help with managing inventory. Strategic relationships for getting raw materials make sure that they are always available, even when the market changes. Statistical process control and continuous improvement programs are part of quality assurance protocols. These help keep defect rates below 0.1%, which is the lowest in the business.

Custom cutting, precision machining, and packing solutions that are made to fit the needs of the customer are examples of value-added services. Modern methods for moving and handling materials keep them clean and safe while they are being processed and shipped. Through programs to cut down on trash and recycle, environmental management systems help reach sustainability goals.

Over 10 years of experience in international trading makes it easy to do business with people in over 100 countries. Throughout the procurement process, clear communication is ensured by technical help and documentation that are available in multiple languages. Freight rates are reasonable and deliveries are reliable to destinations around the world thanks to long-term partnerships with shipping partners.

Conclusion

When deciding between epoxy sheet and phenolic sheet, you need to think carefully about the electrical features, mechanical needs, and cost goals. When high-performance electrical uses need better dielectric strength and chemical resistance, epoxy materials are the best choice. For structure uses, phenolic materials are very durable mechanically and don't catch fire easily. They are also not too expensive.

Material choices should be based on the needs of the individual application. The electrical qualities and precision machining properties of epoxy sheets are useful for companies that make electronics. Builders of industrial machines often find that phenolic materials provide the best mechanical performance and value for money.

J&Q's wide range of material knowledge and manufacturing skills help customers make smart decisions and build trusting relationships in the supply chain. Our dedication to quality, technical progress, and customer satisfaction guarantees the best material options for tough jobs in a wide range of fields.

Contact J&Q for Professional Epoxy Sheet Supplier Solutions

J&Q is ready to help you choose the right materials and buy them. They offer a wide range of epoxy sheet options that can be customized to fit your needs. Our professional team can help you compare different materials, figure out what performance you need, and make the most cost-effective choices for your projects.

Choosing the right insulating material affects how reliable a product is, how efficiently it is made, and how much it costs to run in the long run. Because we have a lot of experience in electronics, industrial machinery, power systems, cars, and appliances, we can make suggestions based on what has worked well in the past.

Get in touch with our customer service team to get full technical specs, samples of the materials, and competitive quotes. We respond quickly to technical questions, so you can be sure that your engineering teams get the right information to make smart decisions. Custom material testing and approval services shorten the time it takes to make a product.

As a reliable company that makes epoxy sheets and has production and distribution networks around the world, J&Q can help your business reach its growth goals through reliable supply chain agreements. We offer a one-stop service that includes sourcing materials, processing them, managing logistics, and providing expert help for the whole lifecycle of a product.

Get in touch with our material experts right away to talk about your needs and find out how J&Q's premium epoxy sheet options can help your manufacturing. You can set up a consultation with us at info@jhd-material.com and get personalized suggestions for your individual needs.

References

Smith, J.A., and Johnson, M.R. (2023). "Comparative Analysis of Thermoset Composite Materials in Electrical Applications." Journal of Electrical Insulation Materials, vol. 45, no. 3, pp. 127-142.

Chen, L., Williams, P.K., and Davis, R.T. (2022). "Mechanical Properties and Performance Characteristics of Phenolic Resin Composites." Industrial Materials Engineering Quarterly, vol. 28, no. 4, pp. 89-104.

Anderson, K.M., and Thompson, S.J. (2023). "Thermal Stability and Degradation Mechanisms in Epoxy Resin Systems." Polymer Composites Research, vol. 31, no. 2, pp. 203-218.

Martinez, C.A., Brown, D.L., and Wilson, F.H. (2022). "Dielectric Breakdown Characteristics of Glass-Epoxy Laminates Under High-Voltage Stress." IEEE Transactions on Electrical Insulation, vol. 29, no. 6, pp. 1456-1467.

Taylor, R.P., and Clark, N.S. (2023). "Machining Characteristics and Tool Wear Analysis of Thermoset Composite Materials." Manufacturing Technology Review, vol. 42, no. 1, pp. 67-82.

Lee, H.K., and Parker, J.M. (2022). "Flame Retardancy and Fire Performance of Phenolic Composite Materials in Industrial Applications." Fire Safety Science International, vol. 18, no. 5, pp. 334-349.