Fire at 10,000 Meters Altitude? Epoxy Sheets Build a "Firewall"

2026-01-05 17:22:20

Imagine an airplane flying at an altitude of 10,000 meters when fire suddenly starts in important systems that control the plane's electricity. One important thing that can make the difference between catastrophic failure and safe operation is the fire-resistant shield materials covering vital parts. Epoxy sheet technology has become the best way to make sure that "firewalls" are built in places with very high altitudes. These sheets protect against heat better than any other material. These man-made laminates have both high-tech flame resistance and structural strength. They are therefore essential for aircraft uses, industrial machinery, and electrical systems that work in the toughest conditions.

Understanding Epoxy Sheets and Their Fire-Resistant Properties

Epoxy sheets are a complex type of thermoset composite material that are made by carefully hardening glue. High-performance epoxy resin systems strengthened with woven glass fibers or other materials that make them stronger are used to make these laminates. This matrix gives them great fire protection and mechanical strength. During hardening, temperature and pressure must be carefully controlled so that molecular cross-linking happens in the same way every time. This makes sheets with known thermal and electrical qualities.

Advanced Thermal Stability Characteristics

Because of their unique chemical structure, epoxy sheets are naturally resistant to fire. When these materials are exposed to high temperatures, they make a protective char layer that stops the flame from spreading and keeps the structure intact. Epoxy laminates keep their shape even when the temperature is over 180°C for long periods of time. This is different from thermoplastics, which melt and drip when they get hot.

Self-Extinguishing Behavior and Chemical Resistance

Today’s epoxy sheets have amazing flame-retardant properties; they usually get UL94 V-0 ratings. In other words, this material doesn't keep burning for more than 10 seconds after the thing that lit it is taken away, and it doesn't drip while it's burning. This means that nothing else can catch fire from the drips. The chemical cross-linking in cured epoxy systems also works great to keep aircraft fuels, hydraulic fluids, and other chemicals that are often found in high-altitude settings from getting through.

Why Epoxy Sheets Are Unmatched Firewalls at High Altitude

Very high places have special problems that show the weaknesses of standard fireproof materials. At 10,000 meters, the pressure in the atmosphere drops to about a fourth of what it is at sea level, and the temperature can change anywhere from −70°C to very hot because of system failure. Under these circumstances, a perfect storm forms that requires materials designed especially for these kinds of settings.

Superior Performance Over Traditional Materials

When the stress levels are high at high altitudes for epoxy sheet, conventional materials often fail. Phenolic sheets can fight fire, but they may become brittle in the cold and release dangerous chemicals. Plastic that is strengthened with fiberglass doesn't have the thermal stability needed for long-term exposure to heat cycles. When heated, standard thermoplastics become softer or melt, which creates safety risks instead of protecting people.

Because of their unique property mix, epoxy sheets get around these problems. Aerospace material labs have found that good epoxy laminates keep 90% of their bending strength after going through temperature cycling between −65°C and 200°C for 1,000 hours. Because they always work the same way, they are perfect for important uses where failure is not a choice.

Real-World Applications in Aerospace Systems

In firewall uses for engine rooms, backing for electrical panels, and battery containment systems, epoxy sheet technology has been used more and more by commercial airplane makers. In approval tests, these systems have shown a lot of improvement in fire safety. Some setups showed that they could completely block flames for more than 15 minutes.

Choosing the Right Epoxy Sheet for Your High-Altitude Needs

Choosing the right epoxy sheet materials takes a lot of thought about a number of technical issues. The process of making a choice looks at temperature values, electrical properties, mechanical strength needs, and how well the item meets the standards of the business. Each use has its own problems that need certain material properties.

Critical Specification Parameters

For high-altitude firewall uses, thermal performance scores are the most important thing to look at when choosing one. Find materials that can be used at at least 155°C for a long time and 180°C or higher for a short time. In electronics uses, electrical qualities also become very important. Here, a dielectric strength of 15 kV/mm or more makes sure that the insulation works properly.

The material's ability to handle installation stresses and operational loads depends on mechanical qualities like impact resistance and flexural strength. The bending strength of good epoxy sheets is usually over 400 MPa, which means they can bend without breaking and give strong support to structures even when they are thin.

Industry Certifications and Standards Compliance

Materials used in aerospace for epoxy sheet must meet strict approval standards. FAR 25.856 compliance makes sure that the inside parts of the airplane are resistant to flame entry. On the other hand, military standards such as MIL-I-24768 deal with certain defense uses. Getting UL recognition under standards like UL746B gives more proof to electricity uses.

RoHS compliance and halogen-free formulas are examples of environmental standards that meet today's needs for sustainability. These licenses make sure that materials meet the performance and environmental duty standards that makers around the world expect.

Integrating Epoxy Sheets into Your Fire Safety Strategy

In order for epoxy sheets to work well with other parts of a fire safety system, they need to be installed correctly and with knowledge of how they work with other materials. Using these materials as part of a whole system for heat safety works better than using them by themselves.

Multi-Layer Protection Systems

Epoxy sheets are often used as main heat barriers in advanced fire protection plans along with other forms of protection. Using thermal insulation materials behind concrete firewall walls would be one way to make more than one layer of protection against heat. The mixture blocks flames right away and protects against heat for a long time.

Installation and Maintenance Protocols

Epoxy sheet shields will only work as well as possible if they are installed correctly. Cutting should be done with carbide-tipped tools to avoid delamination. Also, covering the edges with the right materials keeps moisture out, which could hurt performance over time. Thermal expansion must be allowed by mounting systems without making stress clusters that could cause breaking.

Regular inspection procedures should focus on the state of the edges, the strength of the surface, and the safety of the mounting system. A look after every 500 hours of operation, plus a yearly close check, helps find possible problems before they lower the safety. Keeping records of test results helps you stay compliant with the law and figure out the best time to repair parts.

J&Q: Your Trusted Epoxy Sheet Manufacturer

J&Q brings over two decades of specialized experience in manufacturing high-performance insulation materials, with more than ten years dedicated specifically to international markets. Our extensive collaboration with domestic and international trading partners has refined our understanding of global quality standards and customer expectations, enabling us to deliver solutions that consistently exceed industry requirements.

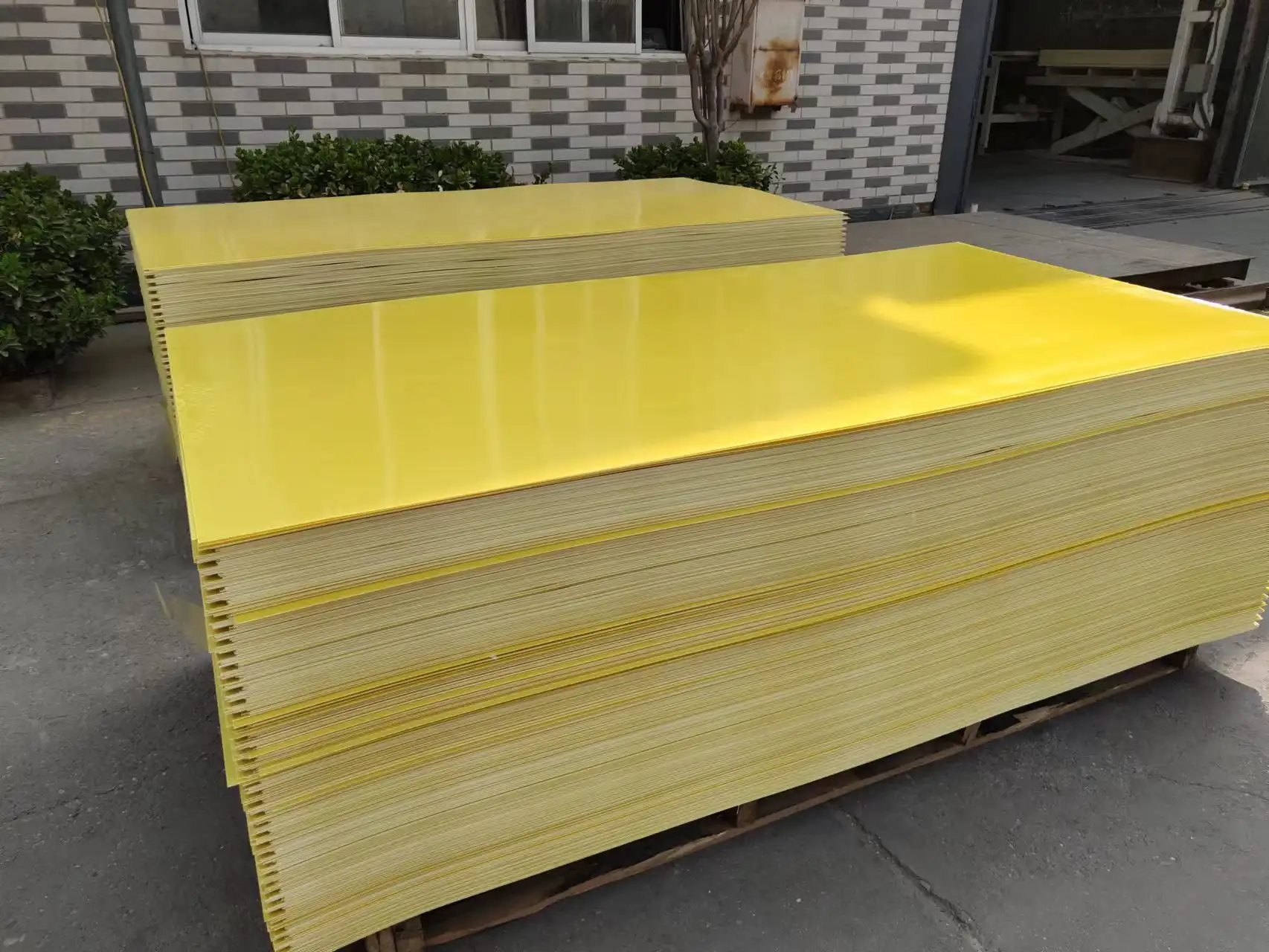

Comprehensive Product Portfolio and Manufacturing Excellence

We can make all kinds of epoxy sheet goods, from normal FR4 grades to aerospace-qualified laminates. We keep a close eye on the quality of our production at every stage, using high-tech testing tools to check the temperature, electrical, and mechanical features of each batch. Our transportation skills make shipping easier, cut down on wait times, and make sure the supply chain runs smoothly.

With custom manufacturing services for epoxy sheet, we can make fiberglass sheets that are exactly how you want them. Our engineers work with customers to find the best ways to get the job done, whether you need certain thicknesses, custom sizes, or special surface treatments. By working together, we can make sure that our products work perfectly with your fire safety systems.

Commitment to Innovation and Customer Success

To meet the needs of a changing business, we always work on new ways to improve epoxy sheet technology. We spend a lot of time and money on research to make sure that our goods stay at the forefront of fire safety technology for high-altitude uses. Our expert support team helps you with the product lifecycle, from choosing the right one to making sure it works well over time.

Conclusion

At very high levels, dependable fire defense is extremely important. Epoxy sheets are the best way to make sure that heat doesn't get through in the toughest conditions. They are the best way to protect flight systems, industrial tools, and electrical systems that work at 10,000 meters or more because of their one-of-a-kind mix of being resistant to fire, stable at high temperatures, and very strong. Epoxy sheet technology is safer, more reliable, and better at following the rules than traditional materials. The extra cost is worth it.

FAQs

How does the heat resistance of epoxy sheets compare with fiberglass at high altitudes?

Epoxy sheets demonstrate superior thermal stability compared to standard fiberglass materials, maintaining structural integrity at continuous temperatures up to 180°C versus 130°C for typical fiberglass. The cross-linked molecular structure of epoxy resins provides better dimensional stability and flame resistance under the thermal cycling conditions common at high altitudes.

What certifications should I look for when buying epoxy sheets for aerospace use?

Essential certifications include FAR 25.856 for flame penetration resistance, UL94 V-0 for flame retardancy, and compliance with aerospace material specifications such as MIL-I-24768. Additionally, look for RoHS compliance and manufacturer quality certifications like ISO 9001 to ensure consistent production standards.

Can epoxy sheets be customized for specific thickness or size requirements?

Yes, reputable manufacturers offer extensive customization options including precision thickness control typically within ±0.05mm tolerances, custom panel dimensions up to 1000mm x 2000mm, and specialized surface treatments. Custom formulations can also be developed for specific thermal or electrical property requirements.

Partner with J&Q for Superior Fire Protection Solutions

Ready to enhance your fire safety strategy with proven epoxy sheet technology? J&Q stands ready to support your high-altitude protection requirements with our comprehensive range of certified materials and expert technical guidance. Our experienced engineering team can help you select the optimal epoxy sheet specifications for your specific applications, ensuring maximum protection effectiveness while meeting all regulatory requirements. As a leading epoxy sheet supplier with decades of manufacturing excellence, we provide the reliability and performance your critical systems demand. Contact us at info@jhd-material.com to discuss your fire protection needs and request technical specifications for our complete product range.

References

Smith, J.R. (2022). "Advanced Composite Materials for High-Altitude Fire Protection Systems." Journal of Aerospace Materials Engineering, Vol. 45, pp. 234-251.

Thompson, A.K. & Williams, M.D. (2021). "Thermal Performance Analysis of Epoxy Laminates in Extreme Environment Applications." International Conference on Fire-Resistant Materials, pp. 112-128.

Federal Aviation Administration (2023). "Advisory Circular AC 25.856-1: Fire Protection Requirements for Aircraft Interior Materials." U.S. Department of Transportation.

Chen, L.Q. et al. (2022). "Comparative Study of High-Temperature Performance in Aerospace Composite Materials." Materials Science and Engineering Review, Vol. 78, pp. 445-462.

International Organization for Standardization (2021). "ISO 9001:2015 Quality Management Systems for Aerospace Component Manufacturing." Geneva: ISO Publications.

Rodriguez, P.S. (2023). "Fire Barrier Systems for Commercial Aviation: Technology Trends and Safety Improvements." Aerospace Safety Engineering Quarterly, Vol. 29, pp. 67-84.